High-sulfur magnetite processing agent and application method thereof

A magnetite ore, high-sulfur technology, applied in flotation, solid separation, etc., can solve the problems of high chemical cost and high cost, and achieve the effect of enhancing the desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further limited below in conjunction with specific embodiments, but the scope of protection is not limited to the descriptions made.

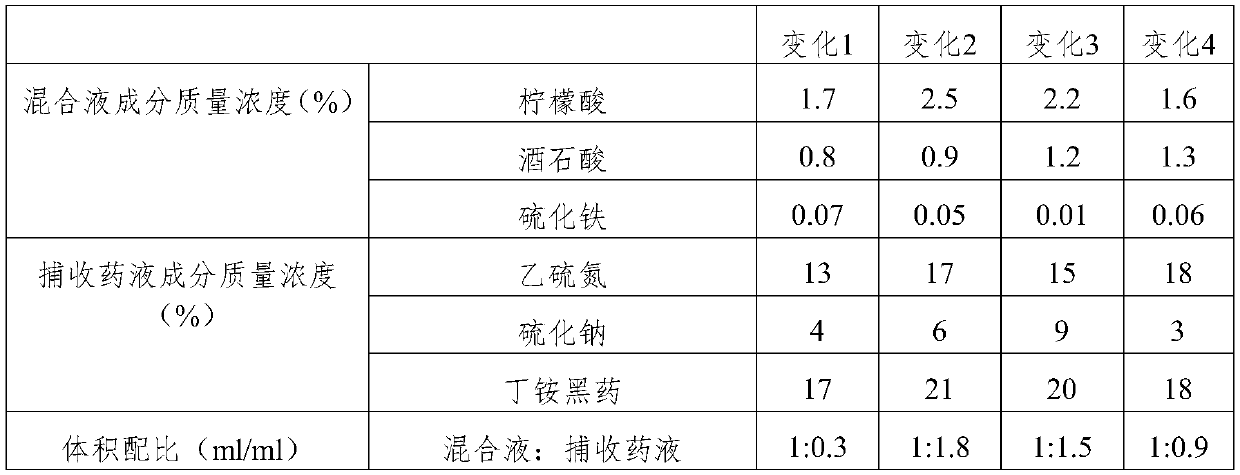

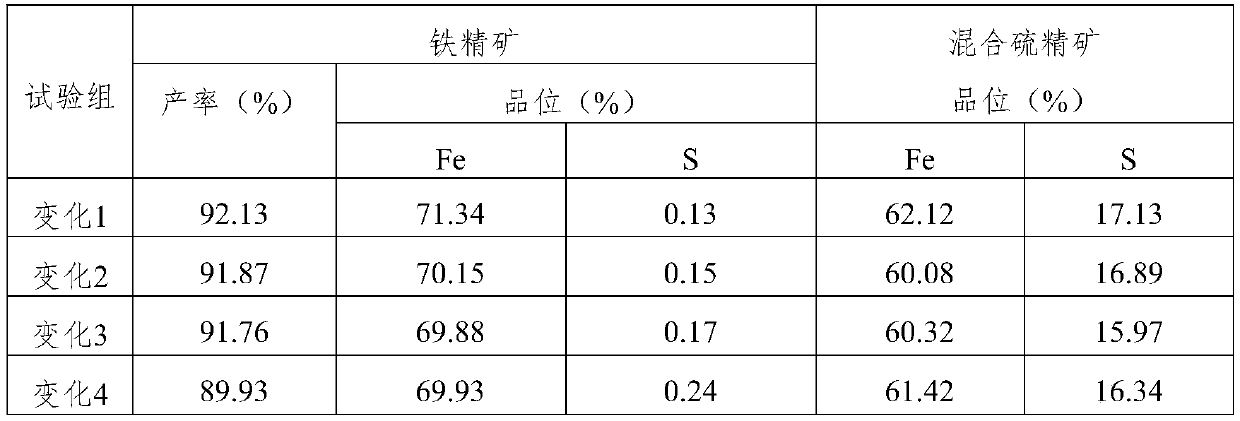

[0016] In the following tests, the high-sulfur magnetite ore beneficiation agent used was prepared and stored separately after the mixed solution was prepared; when the collection liquid was used, it was prepared now, and after the preparation was completed, it was added to the mixed solution and used immediately Flotation removes pyrrhotite in high-sulfur iron concentrate; the preparation process includes the steps of preparing the mixed solution, preparing the collecting liquid, mixing the mixing liquid and collecting the liquid; the step of preparing the mixed solution is After mixing citric acid, tartaric acid and iron sulfide evenly, add them into water, and stir them evenly to obtain the product; the preparation step of the collection medicinal solution is to mix ethiazide, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com