Flotation method for lead and zinc ore difficult to select

A lead-zinc ore and refractory technology, applied in flotation, solid separation and other directions, can solve the problems of low metal grade and recovery rate, high production cost, high lead-zinc mutual content, and achieve ideal separation indicators and lead-zinc mutuality. Contains reduced, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The ore processed in this embodiment contains 1.22% lead and 1.24% zinc.

[0030] The priority flotation process is adopted, specifically, the process of first roughing, two sweeps and three refinements is used to preferentially flotation lead, and the tailings of lead sweeping are adopted to flotation zinc by one process, two sweeps and three refinements. Specifically include the following steps:

[0031] (1) Rough separation of lead: first put the raw ore into the grinding machine, then add lime 2000g / t, zinc sulfate 1000g / t, sodium sulfite 500g / t for grinding, put the raw ore after grinding into flotation tank, add 60g / t of ethyl dithiazide, 10g / t of ethyl xanthate, 40g / t of terpineol oil to carry out flotation, and obtain lead rough concentrate through flotation;

[0032] (2) Lead sweeping: carry out two sweeps to the lead roughing tailings, add 500g / t of zinc sulfate, 250g / t of sodium sulfite, and 30g / t of ethylsulfite to the lead roughing tailings in the first sw...

Embodiment 2

[0048] The ore processed in this embodiment contains 1.22% lead and 1.24% zinc.

[0049]The priority flotation process is adopted, specifically, the process of first roughing, two sweeps and three refinements is used to preferentially flotation lead, and the tailings of lead sweeping are adopted to flotation zinc by one process, two sweeps and three refinements. Specifically include the following steps:

[0050] (1) Rough separation of lead: first put the raw ore into the grinding machine, then add lime 2200g / t, zinc sulfate 1100g / t, sodium sulfite 550g / t for grinding, put the raw ore after grinding into flotation trough, adding 65g / t of ethyl thiazolin, 12g / t of ethyl xanthate, 40g / t of terpineol oil for flotation, and obtained lead rough concentrate through flotation;

[0051] (2) Lead sweeping: carry out two sweeps to the lead roughing tailings, add 550g / t of zinc sulfate, 260g / t of sodium sulfite, and 35g / t of ethylsulfite to the lead roughing tailings in the first sweep ...

Embodiment 3

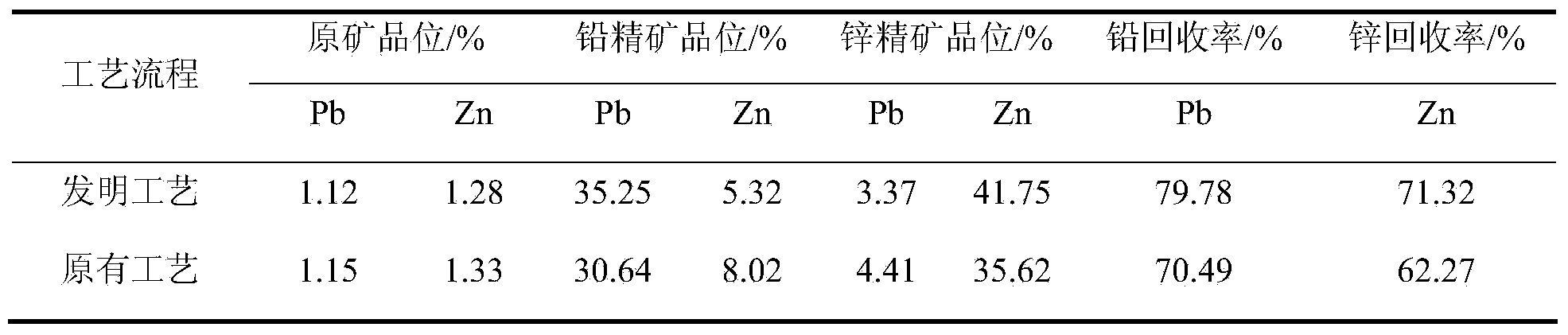

[0067] The process of the invention is applied in industry and compared with the original process index. The processed ore is low-grade refractory lead-zinc ore, and the contents of lead and zinc in the ore are shown in Table 1. The priority flotation process is adopted, specifically, the process of first roughing, two sweeps and three refinements is used to preferentially flotation lead, and the tailings of lead sweeping are adopted to flotation zinc by one process, two sweeps and three refinements. Specifically include the following steps:

[0068] (1) Rough separation of lead: Put the raw ore into a grinding machine, add lime 2000g / t, zinc sulfate 1000g / t, sodium sulfite 500g / t into the mill, put the raw ore after grinding into the flotation cell, add 60g / t of ethyl dithiazide, 10g / t of ethyl xanthate, 40g / t of terpineol oil are used for flotation, and the rough concentrate of lead is obtained through flotation;

[0069] (2) Lead sweeping: carry out two sweeps to the lead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com