Preparation method of modified coral aggregate and basic magnesium sulfate cement gradient composite coral aggregate concrete

A magnesium sulfate and concrete technology, applied in the field of concrete, can solve problems such as increasing safety risks and affecting the durability of Portland cement-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

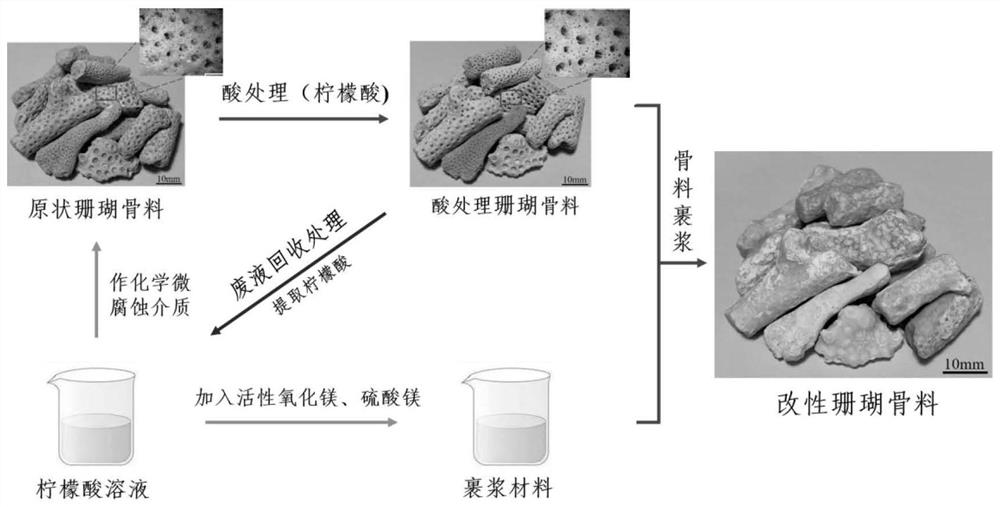

[0036] The present invention provides a kind of preparation method of modified coral aggregate, comprising the following steps:

[0037] (1) Soak and corrode coral aggregates in weak acid aqueous solution to obtain acid-treated coral aggregates;

[0038] (2) Soak the acid-treated coral aggregate in basic magnesium sulfate cement slurry material to obtain modified coral aggregate.

[0039]Preferably, in the step (1): the weak acid is citric acid, and the mass fraction of the weak acid in the weak acid aqueous solution is 0.5-3%, more preferably 0.5%-2%, more preferably 1%. Excessive acid concentration will increase the porosity of coral aggregate, destroy the skeleton structure of coral aggregate, reduce the strength of aggregate, and then reduce the strength of coral concrete.

[0040] In an embodiment of the present invention, the weak acid aqueous solution used is an aqueous citric acid solution, and the present invention has no special requirements on the specific source o...

Embodiment 1

[0052] Step 1: Sieve the undisturbed coral aggregate with a particle size of 5.0-10mm, and dry the coral aggregate at 80°C for 24 hours;

[0053] Step 2: Soak the coral aggregate obtained in Step 1 in 1% citric acid solution for 40 minutes (the mass ratio of coral aggregate to citric acid solution is 1:1.5), filter and remove after soaking (without washing) And drying the coral aggregate at 80°C for 24 hours to obtain the acid-treated coral aggregate;

[0054] Step 3: Take 500 parts of light-burned magnesia powder (the light-burned magnesite powder with active magnesium oxide content of 60%), 333 parts of magnesium sulfate heptahydrate, 340 parts of water and 5 parts of citric acid are mixed and stirred in proportion to prepare alkali formula magnesium sulfate cement grouting material, and put 600 parts of step two gained acid-treated coral aggregates into the basic magnesium sulfate cement grouting liquid and soak for 10 minutes, then remove and filter to obtain modified cora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com