Dust collection system for rewinding machine

A vacuum system and rewinding machine technology, applied in the field of toilet paper production, can solve the problems that the width of the paper web cannot be used directly, the edges on both sides are not neat, and affect the working environment, etc., so as to achieve controllable ventilation speed, ensure cleanliness, and protect the environment good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

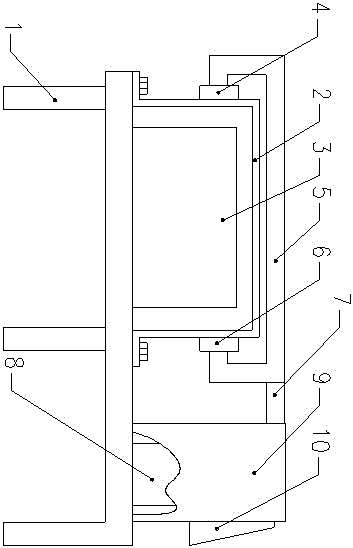

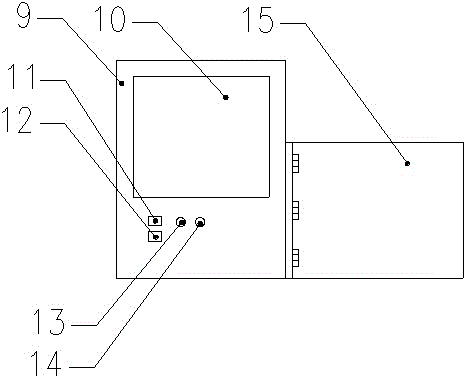

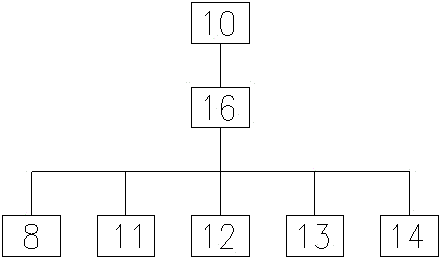

[0017] Such as Figure 1-3 As shown, a dust suction system for a rewinding machine, which includes a frame 1 and a housing 2 fixed on the frame 1 by bolts, the lower side of the housing 2 is provided with a rewinding device 3, the housing The left side of 2 is equipped with an air outlet A4, and the air outlet A4 is connected with an air outlet pipe 5, and the other end of the air outlet pipe 5 is connected with an air outlet B6, and the air outlet B6 is fixed on the right side of the housing 2. side; the exhaust branch pipe 5 is connected with the exhaust main pipe 7, the exhaust main pipe 7 is connected with the exhaust fan 8, the outer side of the exhaust fan 8 is provided with a casing 9, and one side of the casing 9 is embedded with a control The display screen 10, the control switch 11 is arranged on the cover 9 on the lower side of the control display screen 10, the reset switch 12 is arranged on the lower side of the control switch 11, and the working state is arranged...

Embodiment 2

[0020] Such as Figure 1-3 As shown, a dust suction system for a rewinding machine, which includes a frame 1 and a housing 2 fixed on the frame 1 by bolts, the lower side of the housing 2 is provided with a rewinding device 3, the housing The left side of 2 is equipped with an air outlet A4, and the air outlet A4 is connected with an air outlet pipe 5, and the other end of the air outlet pipe 5 is connected with an air outlet B6, and the air outlet B6 is fixed on the right side of the housing 2. side; the exhaust branch pipe 5 is connected with the exhaust main pipe 7, the exhaust main pipe 7 is connected with the exhaust fan 8, the outer side of the exhaust fan 8 is provided with a casing 9, and one side of the casing 9 is embedded with a control The display screen 10, the control switch 11 is arranged on the cover 9 on the lower side of the control display screen 10, the reset switch 12 is arranged on the lower side of the control switch 11, and the working state is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com