Treatment method of organic amine wastewater

A treatment method and organic amine technology, applied in the field of organic amine wastewater treatment, can solve the problems of generating harmful substances, side reaction incineration, secondary pollution, etc., and achieve the effects of reducing energy consumption, small footprint and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

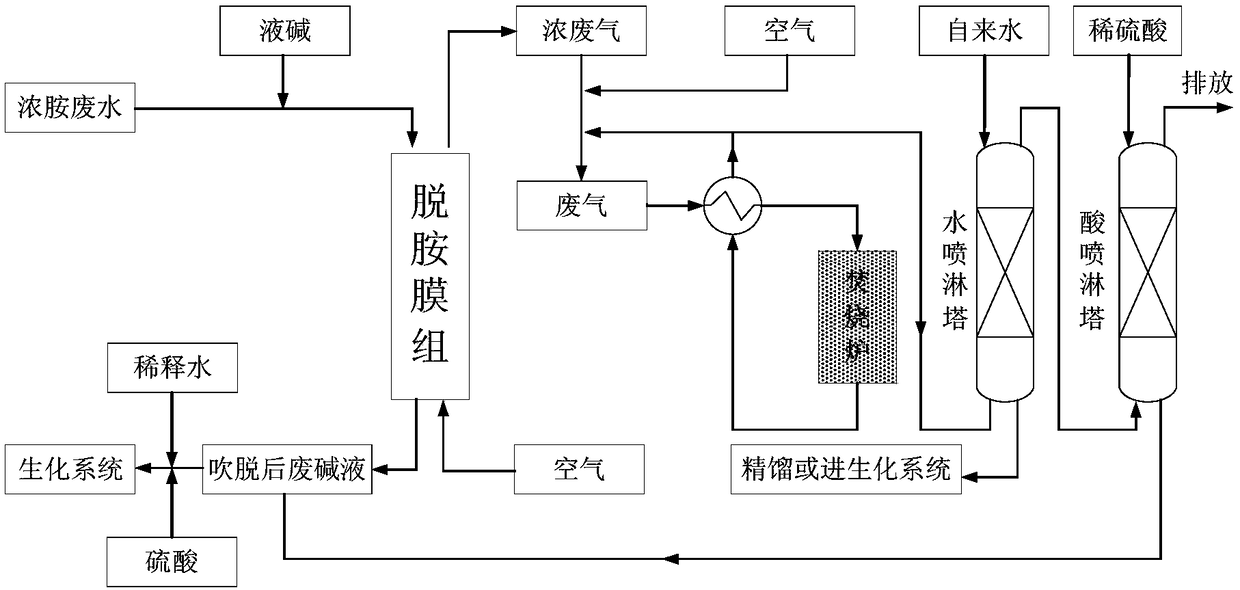

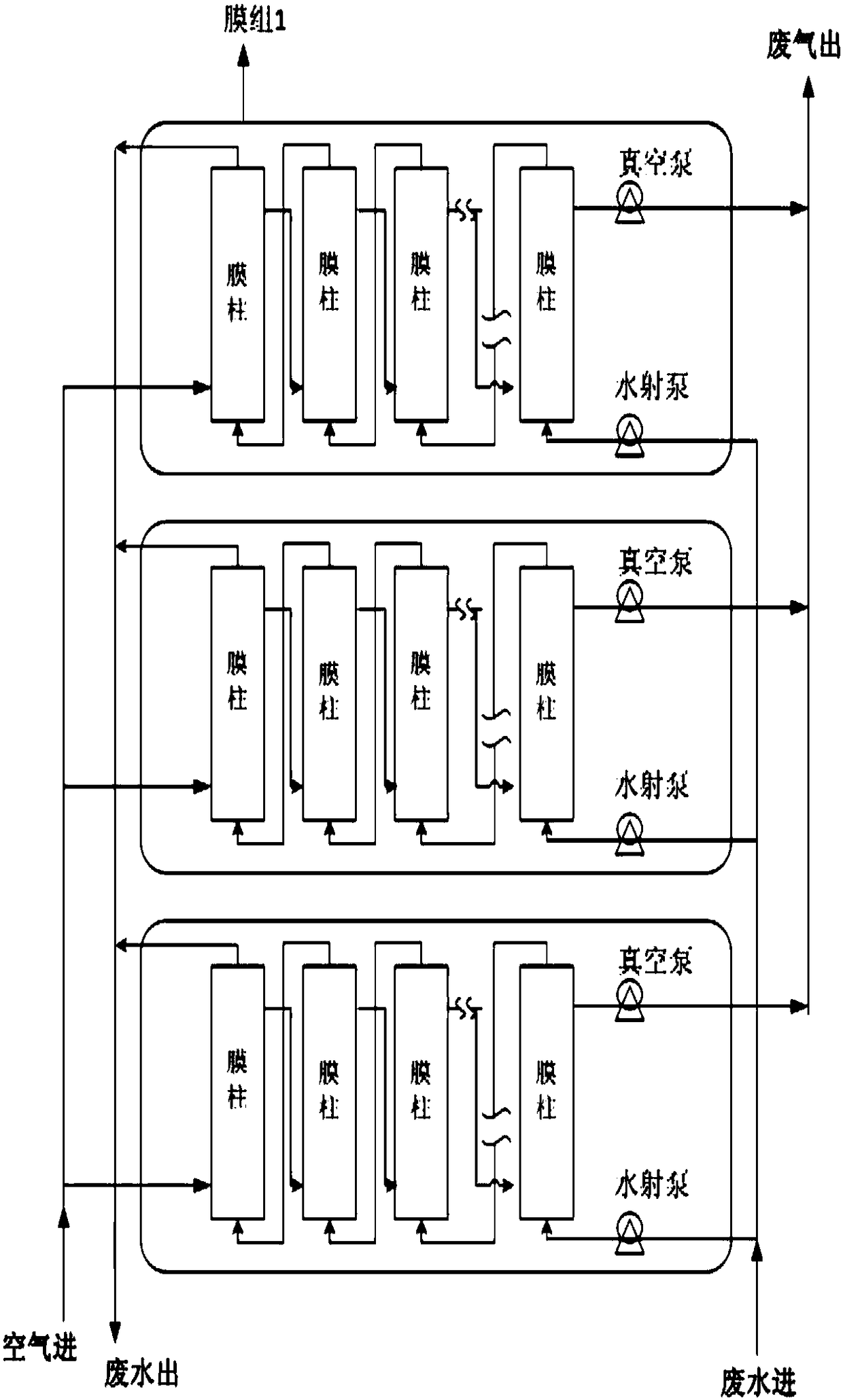

[0066] The processing system adopted in the processing method in embodiment 1 is as figure 1 shown.

[0067] The organic amine wastewater is adjusted to pH and heated and passed into the degassing membrane system. Organic amines and other volatile organic compounds enter the gas phase in the degassed membrane system. The degassed waste lye is diluted and neutralized and then enters the biochemical system for treatment. , the released organic amine waste gas is passed into the regulating tank, and after being diluted in the regulating tank, it passes through the heat exchanger to exchange heat with the incineration tail gas, and then passes into the catalytic incinerator for catalytic incineration. After the incinerated tail gas is cooled by the heat exchanger, a part Enter the regulating tank to dilute and preheat the organic amine waste gas, and the remaining part is passed into the water spray tower for washing with tap water. The water out of the washing is used to dilute t...

Embodiment 2

[0078] A special material company in Zhejiang, the main product is rubber gloves. Solvents DMF and triethylamine are also used in the glove production process, and a large amount of organic solvents can be recovered from workshop production wastewater through rectification. Because DMF is easy to decompose at high temperature, the condensed water of the rectification tower contains a large amount of small molecule organic amines, among which the content of dimethylamine is 1750mg / L, and the concentration of triethylamine is about 800mg / L. The direct entry of this waste water into the biochemical system will cause Wastewater discharge is not up to standard, and there is great difficulty in treatment.

[0079] The processing method is as follows:

[0080] (1) The workshop collects organic amine wastewater, adjusts the pH of the organic amine wastewater to 11, heats it with catalytic incineration tail gas to heat it to 65°C, and passes it into the polypropylene hollow fiber memb...

Embodiment 3

[0085]A chemical company in Jiangsu, the main product is the production of prochloraz and intermediates. In the production process of the product, a large amount of solvent DMF solvent is used, and triethylamine and propylamine are used as raw materials, and a large amount of waste water containing DMF and triethylamine and propylamine is produced per ton of product. The solvent wastewater workshop can recover a large amount of DMF through rectification, but the condensed water of the rectification tower contains a large amount of dimethylamine wastewater; other workshops produce a large amount of triethylamine and propylamine wastewater, of which the content of triethylamine is 2150 mg / L, and the content of propylamine The concentration is about 1100mg / L. The above wastewater enters the biochemical system for treatment through evaporation and condensate dilution, and the operation of the biochemical system is unstable. After adopting the amine-containing wastewater treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com