Hydrogen power generation system

A power generation system, hydrogen technology, applied in the field of power generation systems based on hydrogen energy transmission, can solve the problems of air kinetic energy and pressure not being utilized, achieve high kinetic energy and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

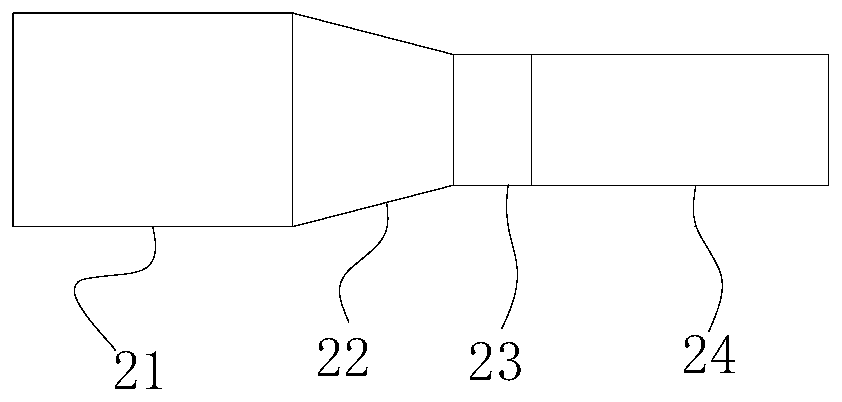

[0045] Such as figure 2 As shown, the specific structure of the Venturi tube 2 in this embodiment is: the Venturi tube 2 includes an inlet section 21 , a contraction section 22 , a throat 23 and a straight section 24 connected in sequence.

[0046] The diameter of the straight section 24 is the same as that of the throat 23. Specifically, the inlet section 21 is a short cylindrical section with a diameter of D; the shape of the constricted section 22 is a tapered tube with a cone angle of is 21°±2°; the throat 23 is a short straight pipe section with a diameter of about 1 / 3~1 / 4D, and the length is equal to the diameter of the pipe; the diameter of the straight section 24 is equal to the diameter of the circle of the throat 23 Tube.

[0047] By changing the diffusion section of the traditional Venturi tube 2 into a straight section 24, high-speed hydrogen with high kinetic energy can be obtained.

Embodiment 3

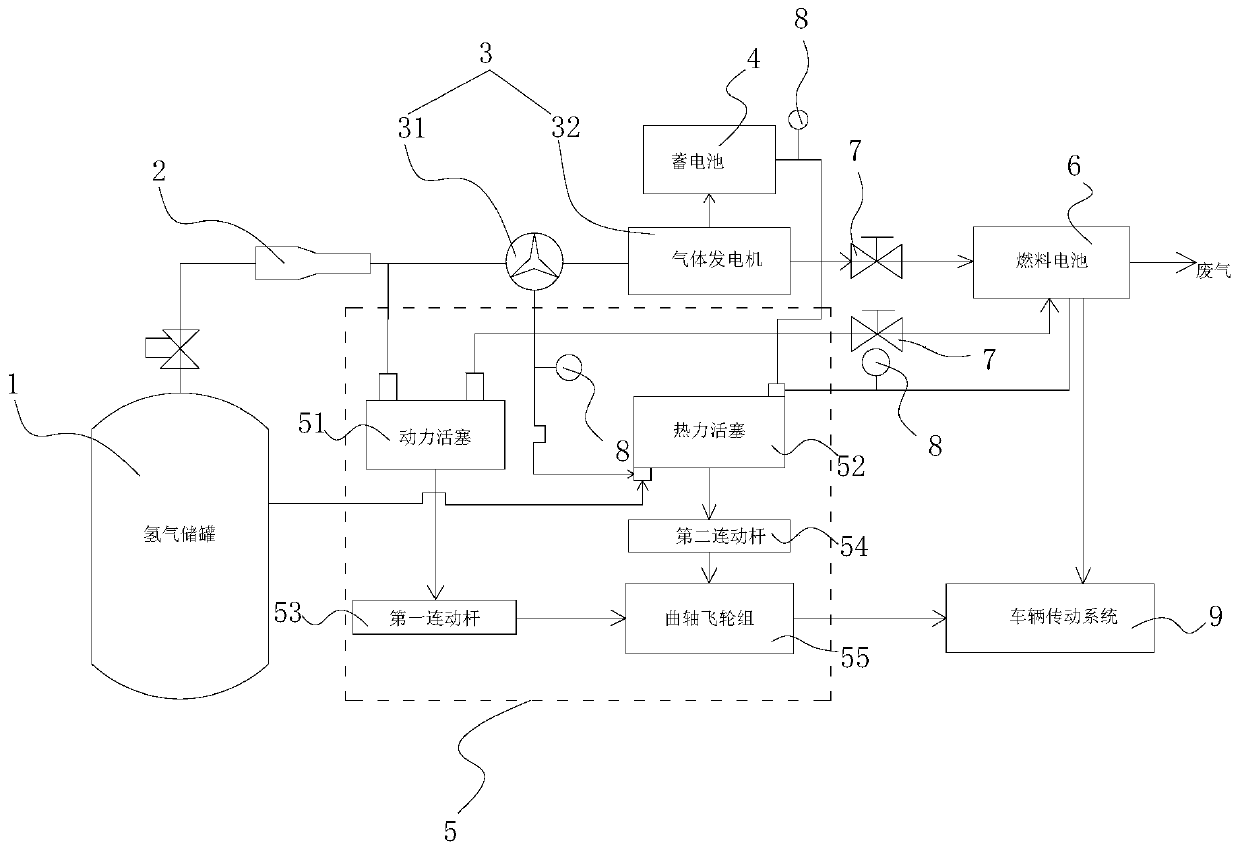

[0049] Such as figure 1 As shown, on the basis of Embodiment 2, this embodiment also includes two gas pressure stabilizing valves 7, one gas stabilizing valve 7 is installed between the wind power generator 32 and the fuel cell 4, and one gas stabilizing valve 7 is installed Between the power piston 51 and the fuel cell 4 .

[0050] Two gas stabilizing valves 7 keep the gas entering the fuel cell 4 at 1.5 atmospheres. In order to allow the fuel cell to absorb hydrogen more efficiently and increase the hydrogen utilization efficiency.

[0051] Concrete work process of the present invention is as follows:

[0052] S1. After the pressurized hydrogen flow in the hydrogen storage tank 1 enters the improved venturi tube 2, the hydrogen flow velocity increases and the pressure decreases;

[0053] S2. The hydrogen flow is divided into two parts, one part generates electricity through the wind power generator set 3, and the generated electric energy is stored in the storage battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com