Pulsometer pump

A water pump and air pressure technology, applied in pressure pumps, mechanical equipment, machines/engines, etc., can solve problems such as waste and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

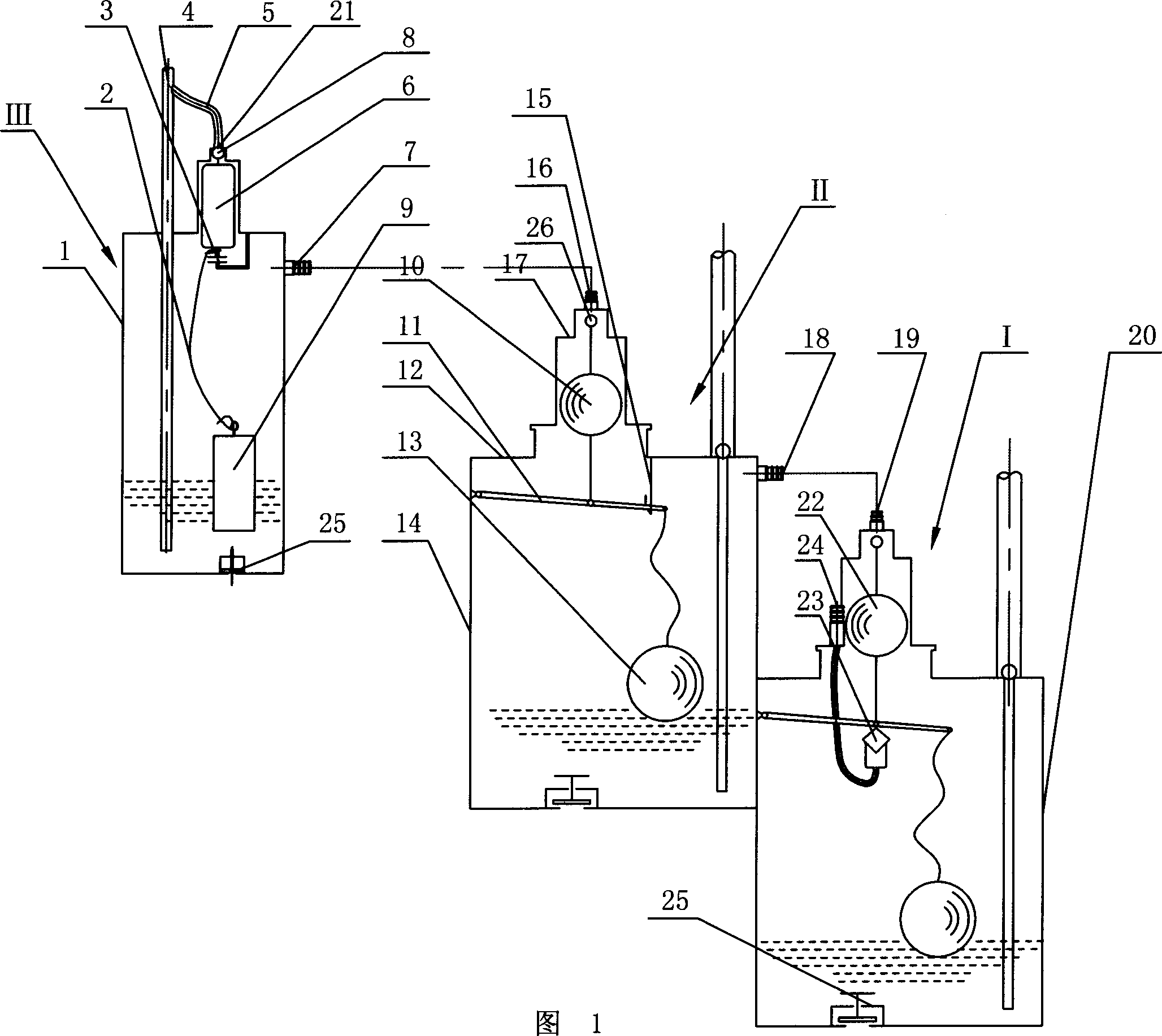

[0011] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0012] As shown in Figure 1, a kind of air pressure pumping machine, it comprises a water inlet 25, drainpipe 4 and air inlet 24, exhaust port 19 and control air intake mechanism 23 and control exhaust mechanism 22 primary pumping The casing 20 of I is characterized in that: the exhaust port 19 of the first-stage pumping water I communicates with the air inlet 18 of the casing 14 of the secondary pumping water II with the water inlet 25, the drain pipe 4, and the exhaust port 16, The casing 14 of the secondary pumping II is provided with a control exhaust mechanism. The control exhaust mechanism of the box body 14 of the secondary water pumping II includes a float valve housing 17 installed on the upper cover plate 12 of the box body 14. There is an exhaust valve corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com