Tunnel type hot air circulation tunnel furnace

A hot air circulation, tunnel-type technology, applied in the field of tunnel furnaces, can solve the problems of uneven color, unequal front and rear air volume, uncontrollable air temperature, etc., to achieve the effect of improving baking quality, convenient air volume, and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

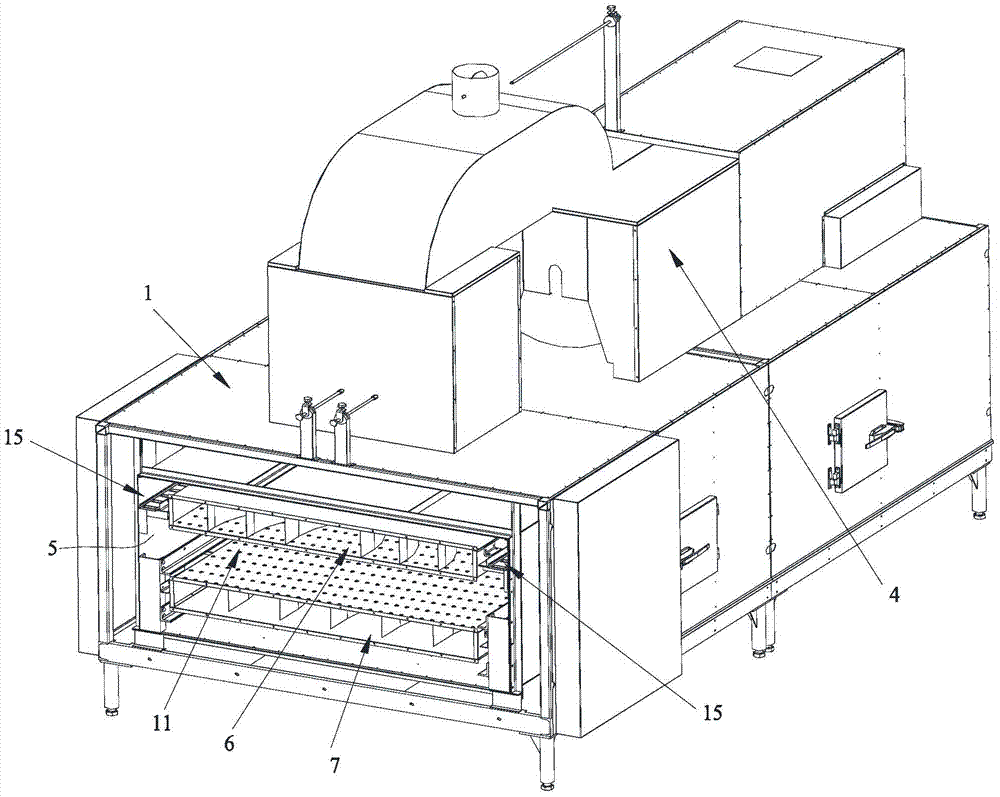

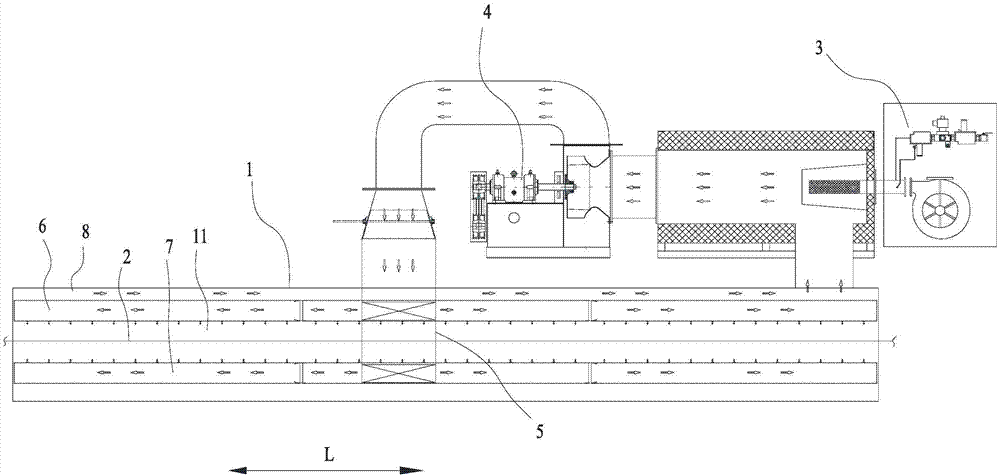

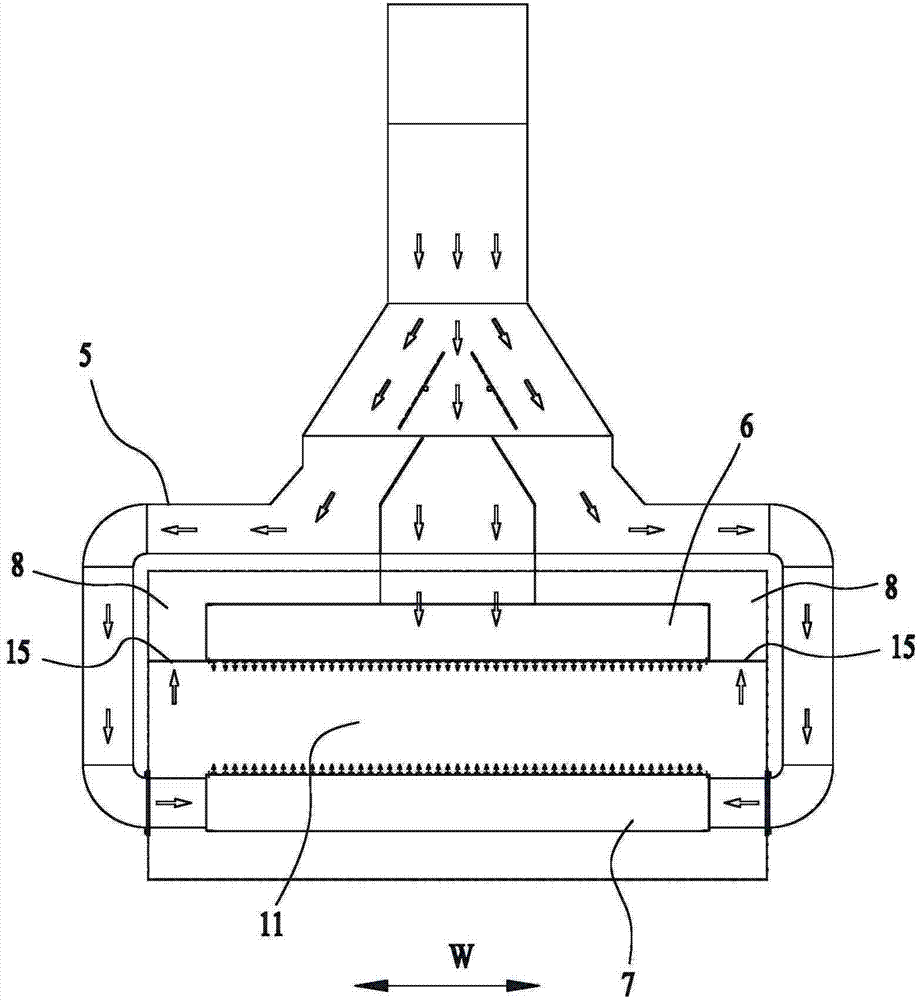

[0035] Such as Figure 1~3 The tunnel-type hot air circulation tunnel furnace shown includes a furnace body 1, a hot air circulation device, a conveyor belt 2 for transporting products to be baked, and a heating device (not shown in the figure) for heating products to be baked. The conveyor belt 2 runs through The furnace body 1 and the hot air circulation device include a hot air generator 3, a fan 4, a four-way joint 5, an upper wind box 6 and a lower wind box 7, and the hot wind generator 3 is connected to the fan 4 and is located outside the furnace body 1.

[0036] Such as Figure 10 As shown, the four-way joint 5 includes a horizontal air inlet shell 51 and two air inlet shells 52 vertically extending from the two ends of the air inlet shell 51. The top surface of the air inlet shell 51 has an inlet 511, and the air inlet shell 51 The bottom surface is provided with a first outlet 512, and the upper ends of the two sub-wind casings 52 are connected with the inlet 511, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com