Rotational flow screening equipment

A technology of sub-equipment and cyclone sieve, which is applied in the direction of cyclone device, the device whose axial direction of the cyclone can be reversed, climate sustainability, etc., can solve the problems of large environmental pollution, many dead ends, and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

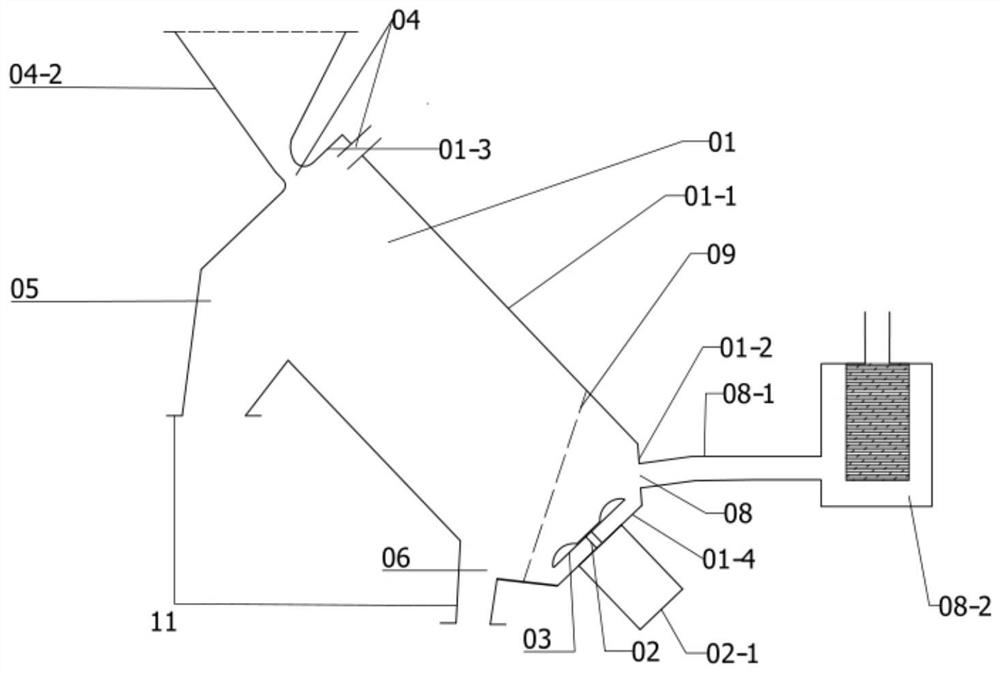

[0027] like figure 1 As shown, according to one aspect of the present application, the present application provides a cyclone screening equipment, specifically: a cyclone air separator, which mainly includes:

[0028] Cylinder body 01, the cylinder body 01 is a cylindrical container composed of a side wall 01-1, a tapered side wall 01-2, an upper end surface 01-3 and a lower end surface 01-4;

[0029] The lower end face 01-4 is provided with a drive shaft 02, and the drive shaft 02 is located on the central axis of the cylinder 01;

[0030] Centrifugal fan blades 03 are arranged on the drive shaft 02;

[0031] A feeding port 04 is opened on the upper end face 01-3 or on the side wall 01-1 close to the upper end face;

[0032] The area of the side wall 01-1 close to the upper end face 01-3 is provided with a first discharge port 05; the area of the joint of the side wall 01-1 and the tapered side wall 01-2 is provided with a second outlet Outlet 06;

[0033] The opening...

Embodiment 2

[0041] According to another aspect of the present application, on the basis of Embodiment 1 of the present application, the present application provides a cyclone screening device, specifically an integrated screening machine.

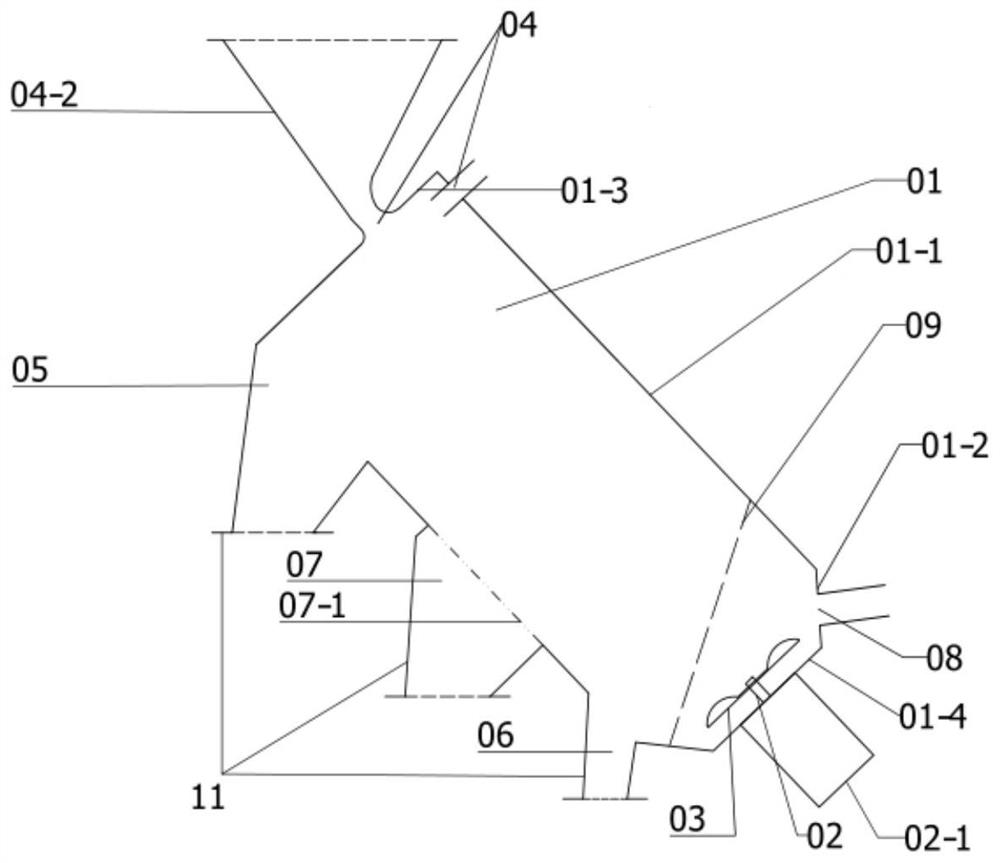

[0042] like figure 2 As shown, specifically, on the basis of Embodiment 1, a third discharge port 07 is opened on the side wall 01-1;

[0043] The third discharge port 07 is located in the middle of the side wall 01-1, and is located between the first discharge port 05 and the second discharge port 06;

[0044] The opening direction of the third discharge port 07 is downward or downward;

[0045] The third discharge port 07 is provided with a third discharge port screen 07-1, and the third discharge port screen 07-1 is smoothly and tightly connected with the inner wall of the cylinder.

[0046] The specific working principle of the second embodiment of the present application is as follows: as in the first embodiment, the upwardly moving light mater...

Embodiment 3

[0048] According to another aspect of the present application, on the basis of the second embodiment of the present application, the present application provides a cyclone screening device, specifically a cyclone screening machine.

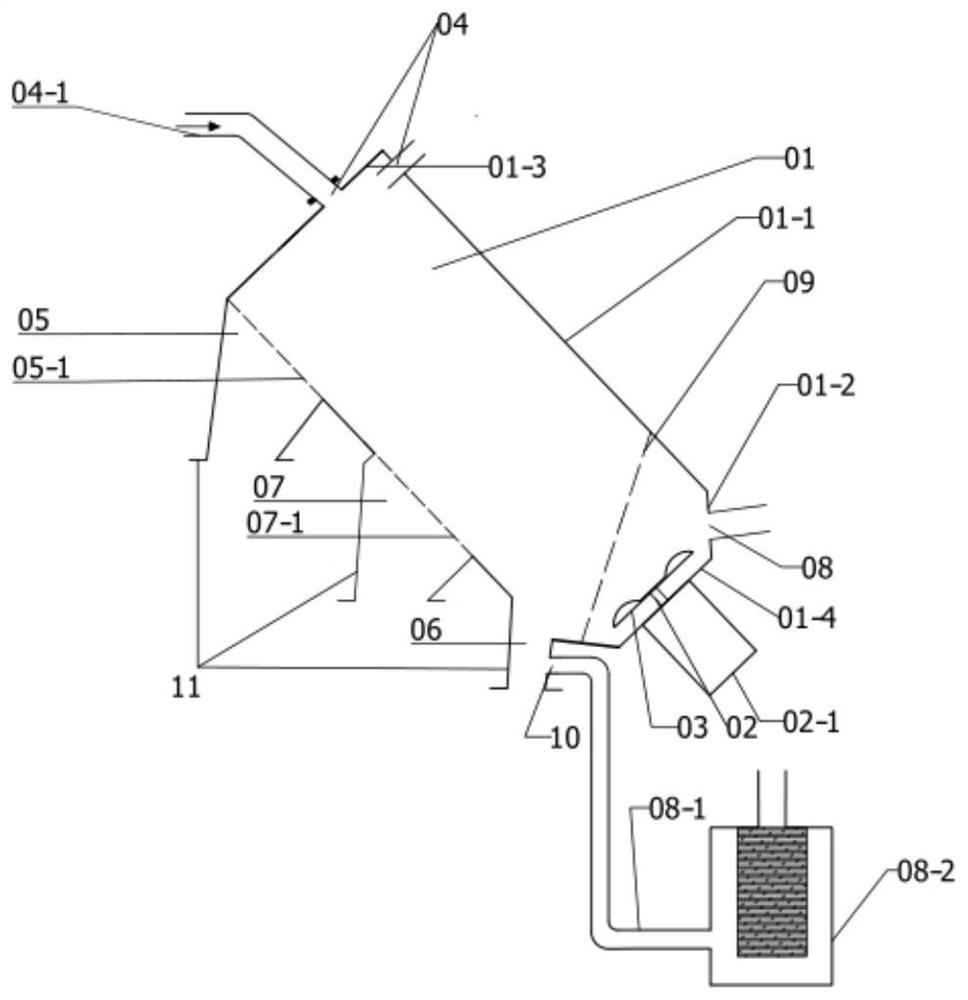

[0049] like image 3 As shown, specifically, on the basis of Embodiment 2, a first discharge port screen 05-1 is installed on the first discharge port 05;

[0050] The aperture of the first outlet screen 05-1 is smaller than or equal to the aperture of the third outlet screen 07-1 installed in the third outlet 07;

[0051] The first discharge port screen 05-1 is smoothly and tightly connected with the inner wall of the cylinder.

[0052] This embodiment is suitable for occasions where there is no floc in the material and fine powders or particles of different particle sizes need to be separated. The specific working principle is as follows: the drive shaft drives the centrifugal fan blades to rotate, and a rotating airflow is formed inside the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com