Wind-heat cleaning system for automobile glass

A technology for automotive glass and cleaning systems, applied in the field of cleaning systems, can solve problems such as inability to protect against rain, potential safety hazards, and impact on drivers and passengers, and achieve the effects of not being prone to visual fatigue, avoiding waste, and clear vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

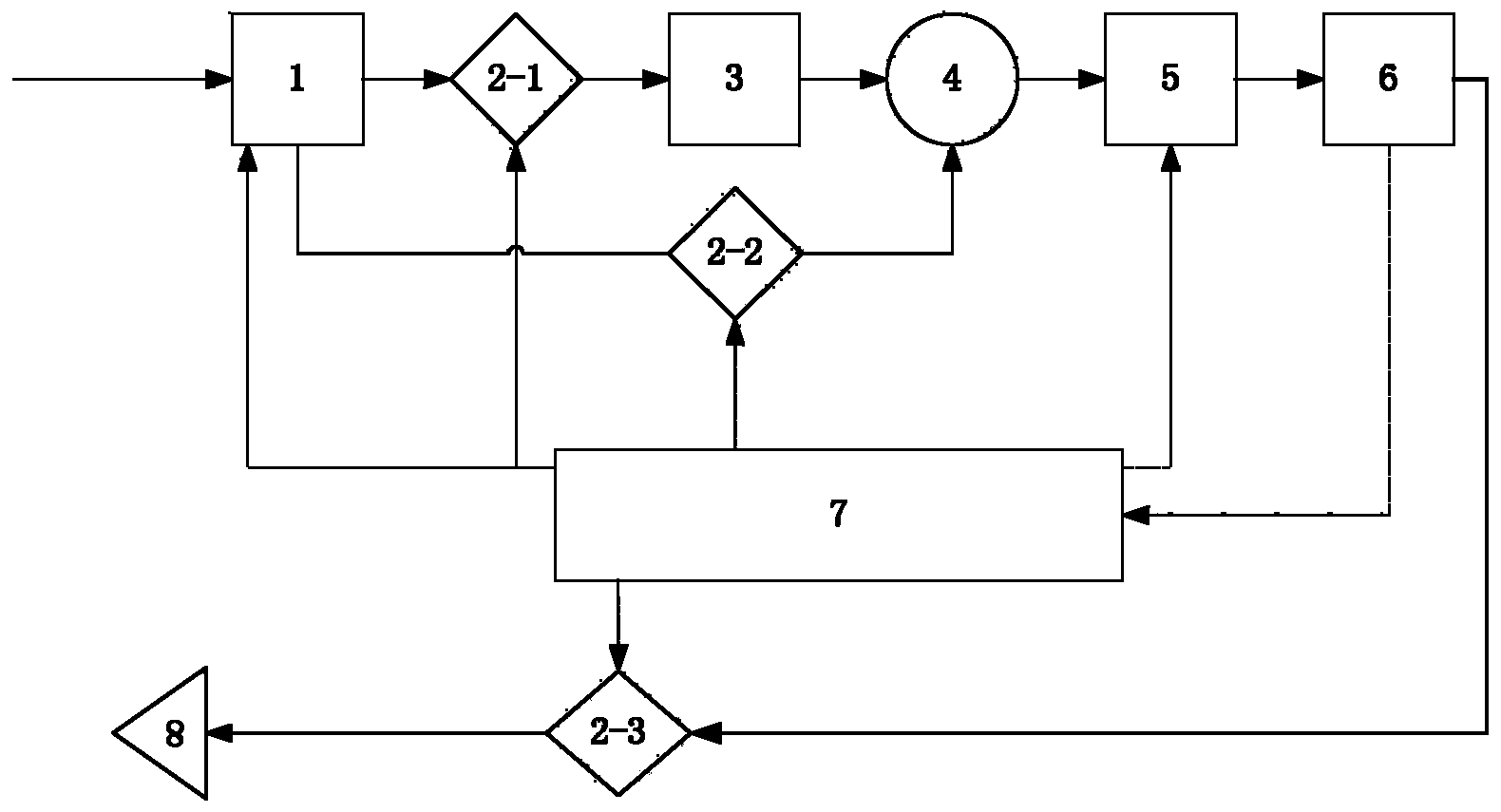

[0016] Such as figure 1 As shown, the solid line with arrows in the figure is the air supply pipe, and the direction of the arrow indicates the direction of air flow; the dotted line with arrows indicates the signal line.

[0017] The present invention is an air-heat cleaning system for automobile glass, comprising an air compressor 1 , an exhaust waste heat exchanger 3 , a temperature and pressure sensor 6 , an air mixing valve 4 , an electric heater 5 , a controller 7 and an air spray nozzle 8 . The air inlet of the air compressor 1 is connected with the air outside the vehicle, and the air outlet is connected with the air inlet of the exhaust heat exchanger 3 through the first electromagnetic valve 2-1, and the air outlet of the exhaust heat exchanger 3 is connected with the air mixing valve 4. The air inlet is connected, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com