High efficient and energy saving tea leaf baking and fragrance improving machine and use method thereof

A high-efficiency, energy-saving, aroma-increasing machine technology, which is applied in tea treatment before extraction, can solve the problems that cannot meet the specific technical requirements of thermal processing, the appearance of tea does not frost, and the quality of tea is not good enough, so as to achieve large thermal inertia and improve baking The effect of quality and large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] A detailed description will be given below in conjunction with the accompanying drawings and embodiments.

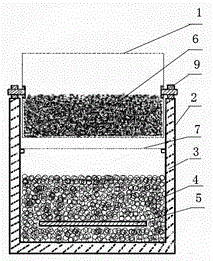

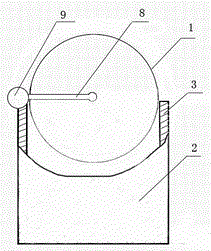

[0027] as attached figure 1 , 2 As shown in 3, a complete technical solution for high-efficiency and energy-saving tea roasting and aroma enhancing machine is given:

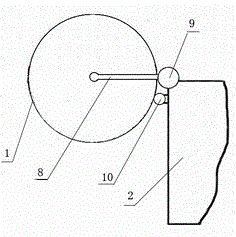

[0028] It includes a drum-shaped baking cage (1) and a baking body; the baking body includes a chassis (2), a heat insulation layer (3), a pile of heat storage particles (4), and a Electric heating device (5), tea dust isolation net (7), the roasting body device has a device for moving the drum-shaped baking cage (1) into or out of the roasting body, and drives the drum-shaped baking cage (2) to rotate s installation;

[0029] The device for moving the barrel-shaped baking cage (1) into or out of the baking body includes a low-speed motor fixed on the baking body, a drive shaft (9) connected to the rotating shaft of the low-speed motor, and a drive shaft (9) fixed on the baking body for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com