Optical switch collimator baking rack

A technology of collimator and baking rack, applied in the direction of dryer, drying room/container, etc., can solve the problems of collimator falling, affecting production efficiency, unstable collimator quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

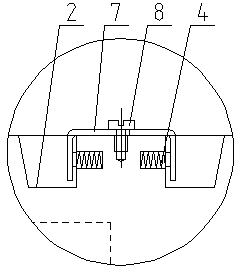

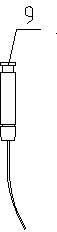

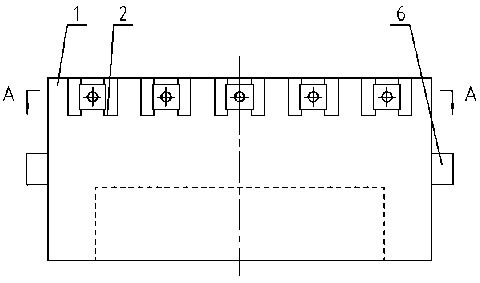

[0021] Taking the collimator 9 of two optical fibers of the optical switch as an example, the principle and process of the baking rack of the optical switch collimator of the present invention are illustrated (see Figure 6 and Figure 7 shown):

[0022] 1. Glue injection

[0023] Put the optical fiber into the glass sleeve as required, and inject glue into the glass sleeve;

[0024] 2. Install spring assembly 3

[0025] Install a spring 5 in the spring groove 4 on one side of the wedge-shaped workpiece groove 2, and one end of the spring 5 stretches into the workpiece groove 2, and adjust the appropriate extension amount with the spring compression of the spring 5;

[0026] 3. Install the positioning shrapnel 7

[0027] A U-shaped positioning shrapnel 7 is installed between the two workpiece grooves 2. One side of the positioning shrapnel 7 is fixed on the frame 1 by screws 8. The two U-shaped wings extend into the workpiece groove 2. 5 end contacts;

[0028] 4. Instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com