Heat radiation type simulation charcoal baking tea baking machine and using method

A technology of heat radiation and roasting machine, which is applied in tea treatment before extraction, etc. It can solve the problems of not meeting the specific technical requirements of thermal processing, the appearance of tea leaves will not frost, and the quality of tea leaves is not good enough, so as to achieve large thermal inertia and improve roasting quality , the effect of large heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] A detailed description will be given below in conjunction with the accompanying drawings and embodiments.

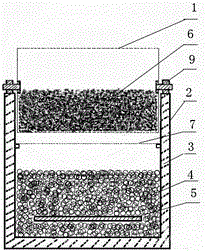

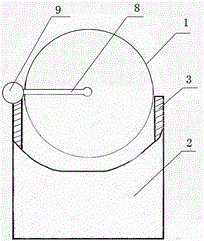

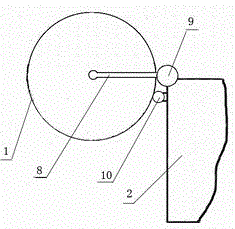

[0028] as attached figure 1 , 2 As shown in 3, give a complete heat radiation type imitation charcoal roasting tea roasting machine technical scheme:

[0029]It includes a drum-shaped baking cage (1) and a baking body; the baking body includes a chassis (2), a heat insulation layer (3), a pile of heat storage particles (4), and a Electric heating device (5), tea dust isolation net (7), the roasting body device has a device for moving the drum-shaped baking cage (1) into or out of the roasting body, and drives the drum-shaped baking cage (2) to rotate device; the materials selected for the heat storage particle stack (4) are preferably river pebble particles, volcanic stone particles and pure quartz sand particles;

[0030] The device for moving the barrel-shaped baking cage (1) into or out of the baking body includes a low-speed motor fixed on the baking body, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com