Baking channel device for embossing machine

A printing machine and drying tunnel technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of easy falling off of printing parts and large drying tunnel, so as to save floor space and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

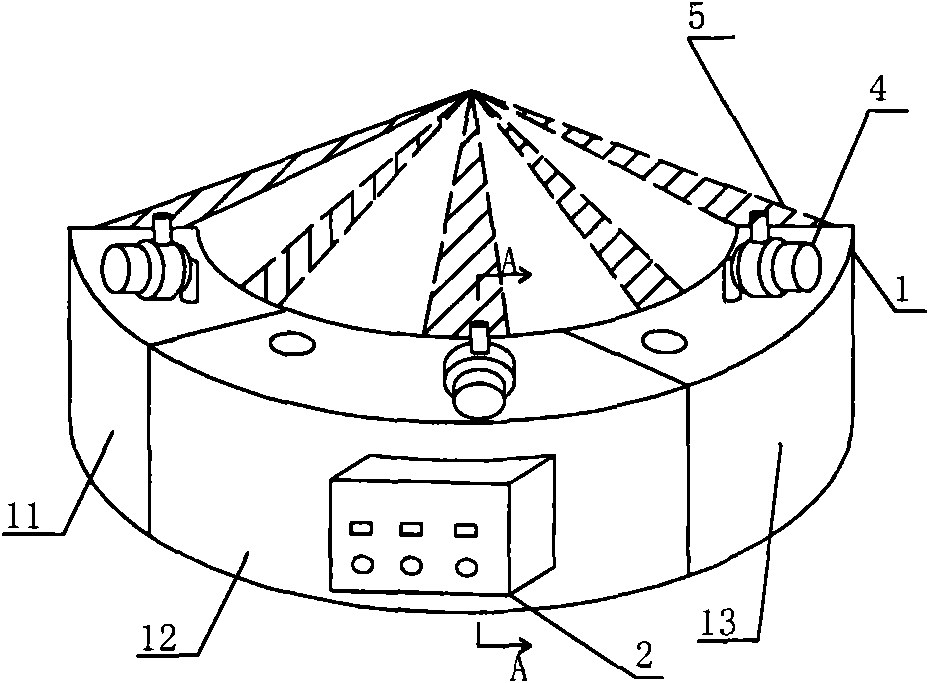

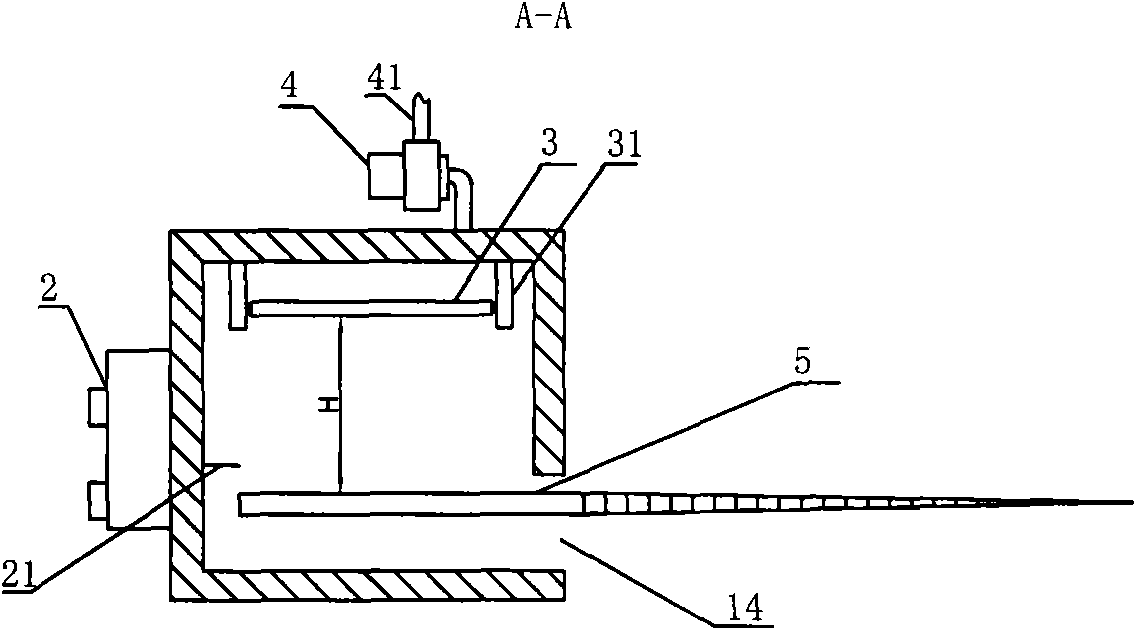

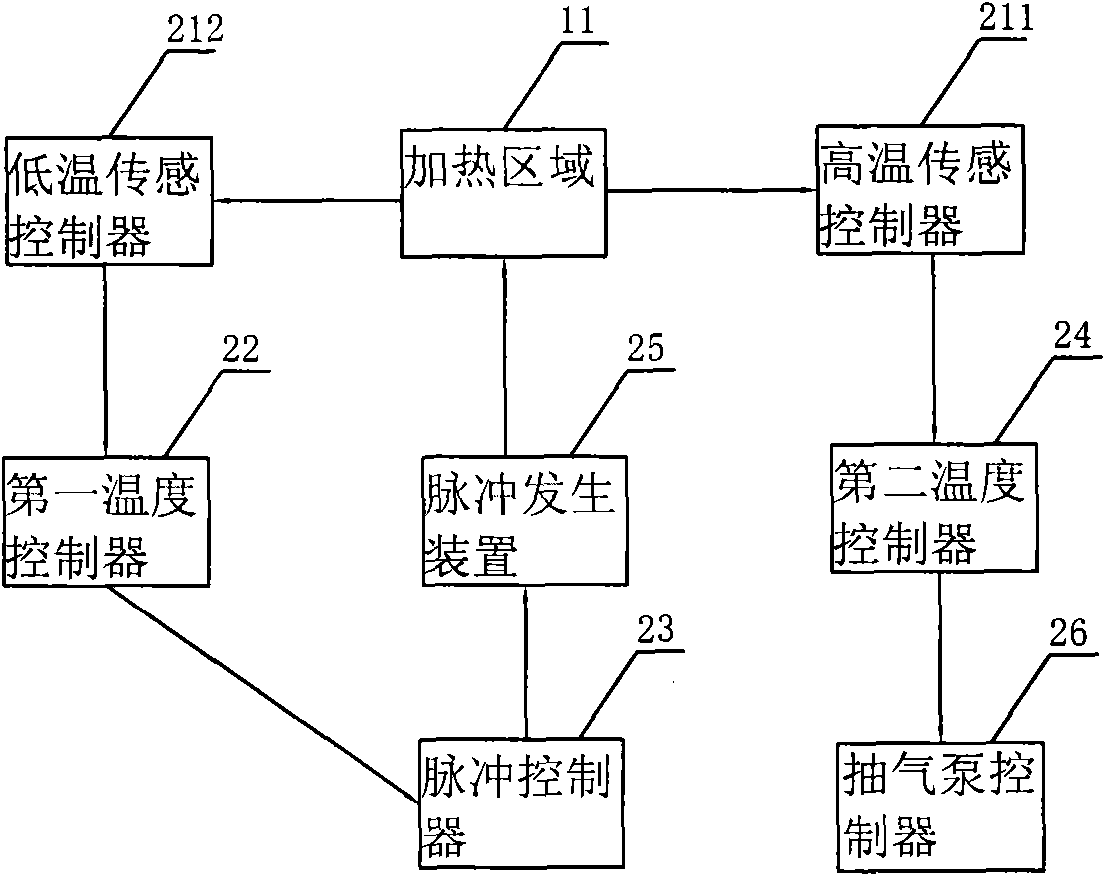

[0018] Such as figure 1 , figure 2 , image 3 As shown, the drying tunnel device for a printing machine has a pipeline 1, a heating device and a ventilation device. The pipeline 1 is an arc-shaped pipeline provided with a control box, and the side wall of the pipeline 1 is provided with a slit for the passage of the template 5 for printing. 14. The heating device is a carbon wave infrared radiator 3 evenly arranged. The carbon wave infrared radiator 3 is fixed on the top of the inner wall of the pipeline 1 through a bracket 31. The distance H between the carbon wave infrared radiator 3 and the template 5 is 30cm, and the ventilation device is The air pump 4, the air pump 4 is arranged on the top of the pipeline 1, the air pump 4 has an exhaust pipe 41, the exhaust pipe 41 leads to the outdoors, the control box 2 controls the carbon wave infrared radiator 3 and the air pump 4, the pipeline 1 There are three temperature zones of the first temperature zone 11, the second tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com