Tool for spraying car rear door trim protecting plate

A technology for back doors and automobiles, applied in the direction of spraying devices, devices for coating liquid on the surface, coatings, etc., can solve the problems of plastic plate bending becoming smaller, affecting product assembly clearance, plastic plate warping and deformation, etc., to achieve It is not easy to warp and deform, guarantee the quality, and ensure the effect of the quality requirements of the assembly gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

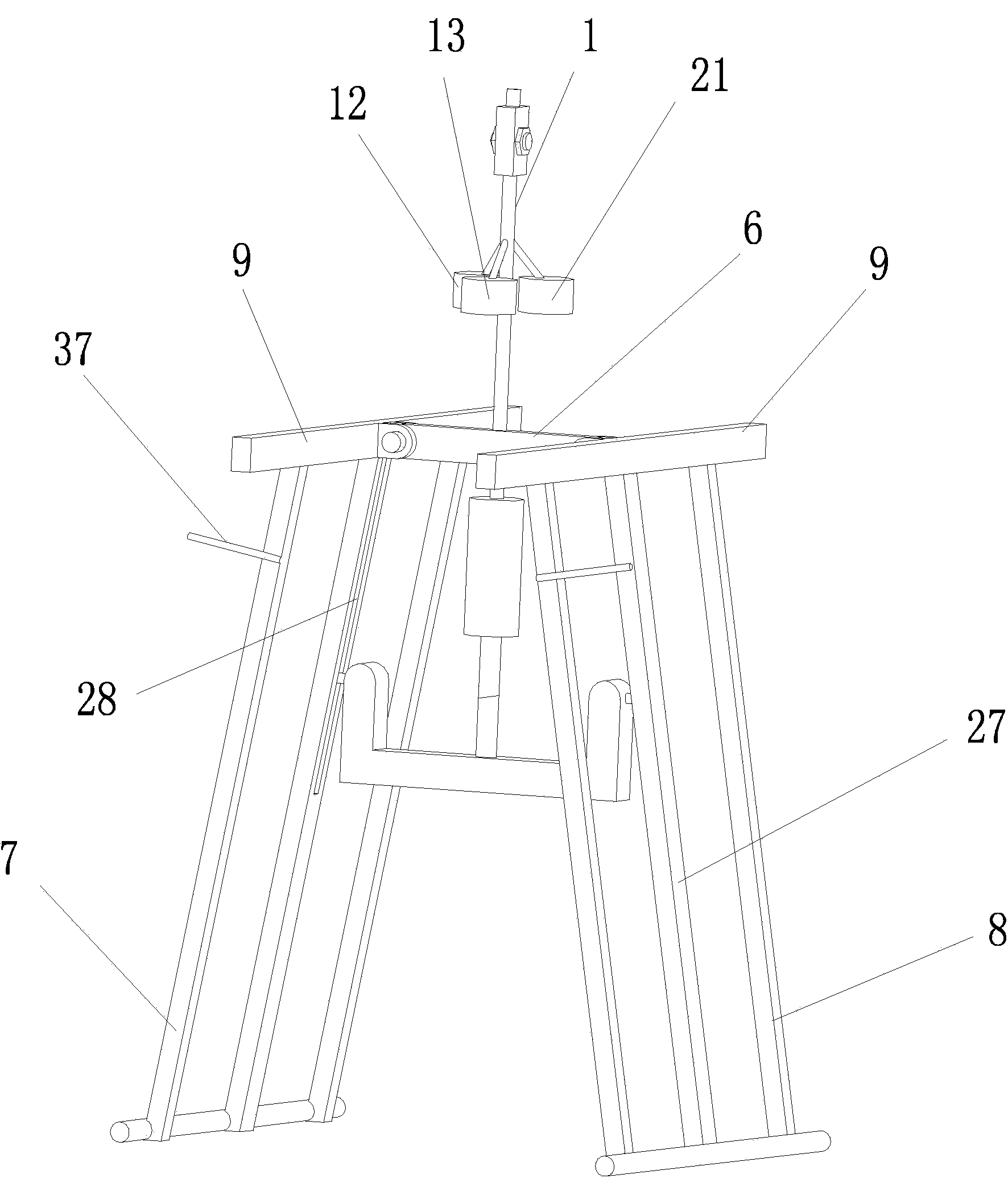

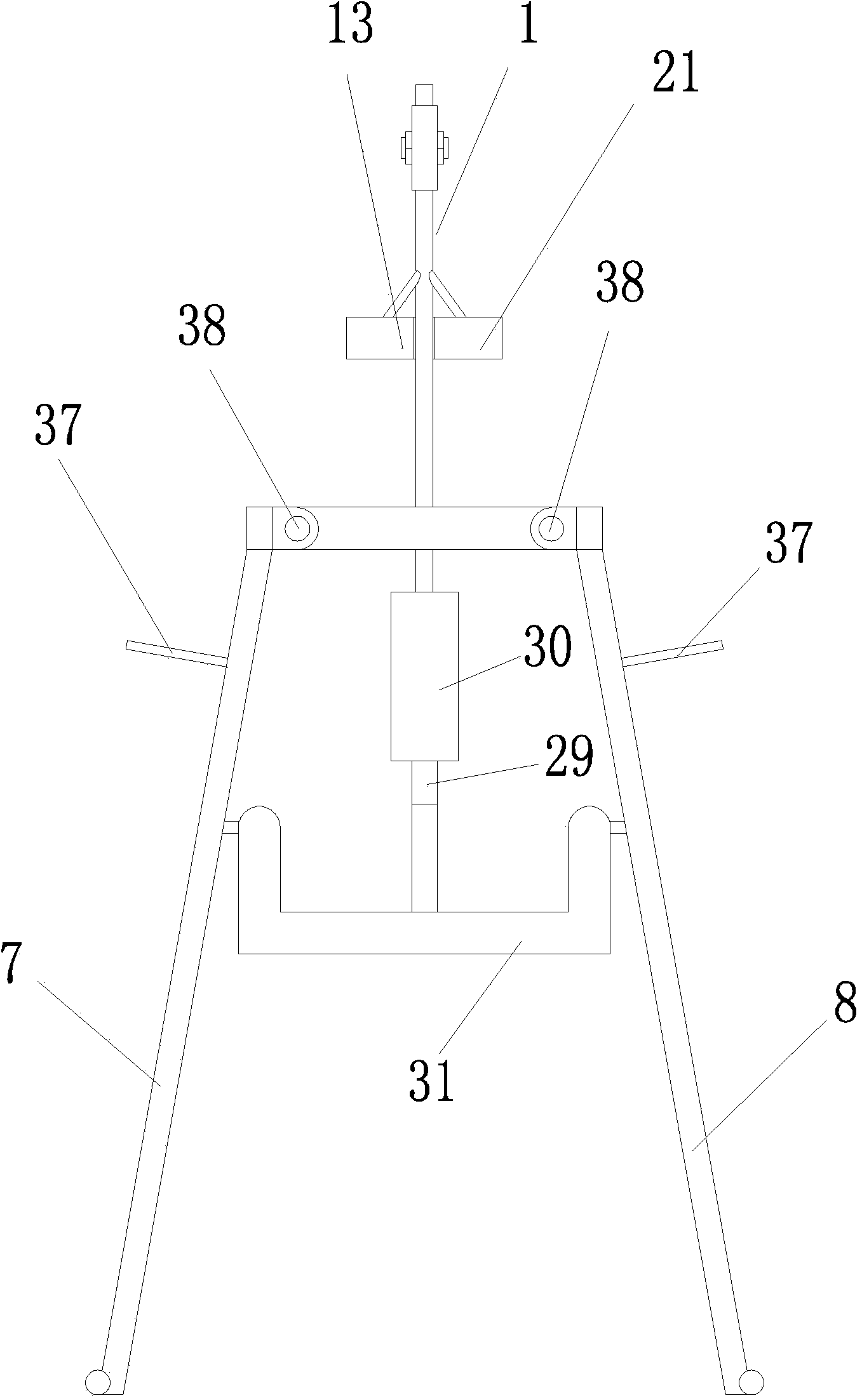

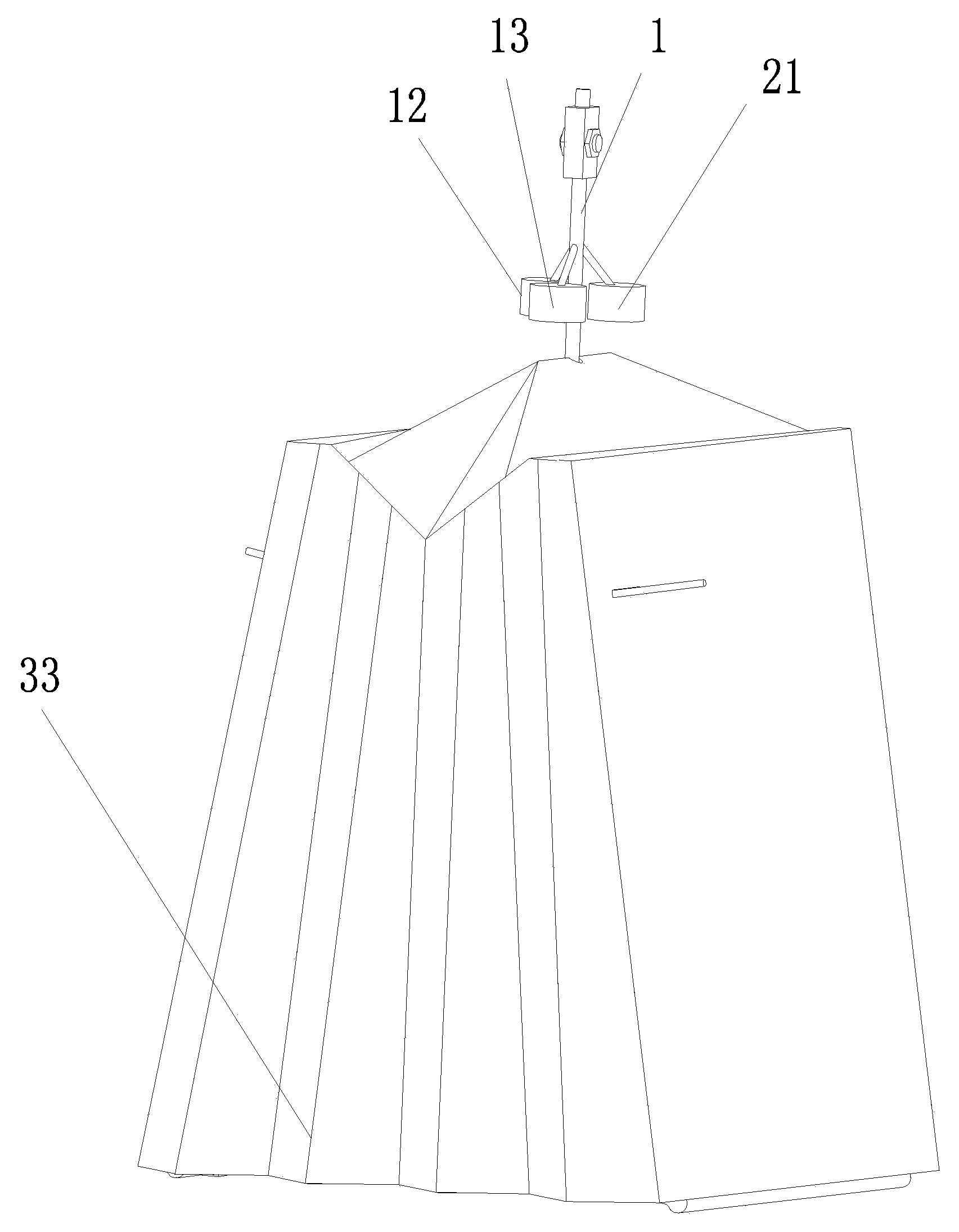

[0028] Embodiment: a kind of spraying frock of automobile rear door interior guard plate, see figure 1 , figure 2 as shown,

[0029] It includes a spreader 1, No. 1 connecting pipe 2, No. 2 connecting pipe 3, connecting rod 4, and a hose 5 made of flexible material. A horizontally arranged installation block 6 is fixedly connected to the lower end of the spreader. The ends are respectively connected with left window frame 7 and right window frame 8, and the upper cross bar 9 of left window frame and right window frame is made of heat-conducting material; There is an upper cross bar lumen 10, and the upper cross bar lumen on the left window frame communicates with the upper cross bar lumen of the right window frame through the No. 1 communicating tube, and one end of one of the upper cross bar lumens is provided with The lumen communication hole 11 of the upper cross bar that the lumen of the upper cross bar communicates; it also includes an active thrust tube 12 and a passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com