Toasting process that can reduce phenol release in flue-cured tobacco

A technology of curing process and process method, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems such as the release amount is not paid attention to, and has not been seen, and achieves extremely strong operability, obvious effect, and reduced phenol release amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

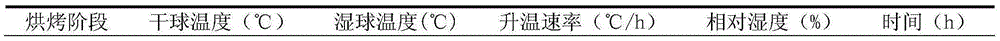

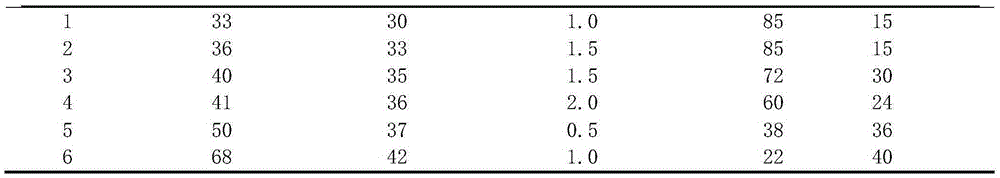

[0051] The flue-cured tobacco in this embodiment selects the middle leaves (9-11 leaves) of the cultivar Yunyan 85 in Fengdu County, Chongqing as the test object, and the fresh tobacco leaf samples come from the same tobacco field and the same farmer, so the transplanting period, harvesting and field management The measures are the same, the soil water and fertilizer are uniform, and the growth of tobacco leaves is normal and consistent. The roasting is carried out in the local intensive barn. When weaving the poles to load the tobacco, it is ensured that the fresh weight of each pole is basically the same, and the distance between the upper, lower, left and right poles in the kang is balanced and consistent. Tobacco leaves cured under the existing process conditions were used as control samples, and the test samples of the present invention were cured according to the parameter conditions provided in Table 1 below. After the curing, the phenol release amount of the sample tob...

Embodiment 2

[0065] The upper leaves (13-15 leaf positions) of the cultivar Yunyan 85 in Fengdu County, Chongqing were selected as the test object, and the selection of fresh tobacco leaf samples and the preparation of the baking test were the same as in Example 1. The test samples of the present invention were baked according to the parameter conditions provided in Table 5 below. After the curing, the phenol release amount, appearance quality and internal quality of the sample tobacco leaves were analyzed and tested.

[0066] Table 5 baking process provided by the present invention

[0067]

[0068] See Table 6 for the detection results of the phenol release amount of the samples. It can be seen that the process provided by the invention has an obvious effect on reducing the release of phenol, and compared with the existing baking process, the release of phenol can be reduced by 45.70%.

[0069] The detection result of the sample phenol release amount after table 6 bakes

[0070] ...

Embodiment 3

[0078] The upper leaves (13-15 leaf positions) of the cultivar Yunyan 85 in Fengdu County, Chongqing were selected as the test object, and the selection of fresh tobacco leaf samples and the preparation of the baking test were the same as in Example 1. The test samples of the present invention were baked according to the parameter conditions provided in Table 9 below. After the curing, the phenol release amount, appearance quality and internal quality of the sample tobacco leaves were analyzed and tested.

[0079] Table 9 baking process provided by the present invention

[0080]

[0081] See Table 10 for the detection results of the phenol release amount of the samples. It can be seen that the process provided by the invention has an obvious effect on reducing the release of phenol, and compared with the existing baking process, the release of phenol can be reduced by 31.57%.

[0082] The detection result of the sample phenol release amount after table 10 bakes

[0083] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com