Well type high-temperature resistance furnace for heat treatment of PAN (polyacrylonitrile) based carbon felt

A high-temperature resistance furnace and carbon felt technology, which is applied in the field of high-temperature industrial furnaces, can solve problems such as poor heat shielding, poor heat preservation, and complex structure of heating elements, and achieve the effects of easy maintenance and replacement, reasonable layout, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

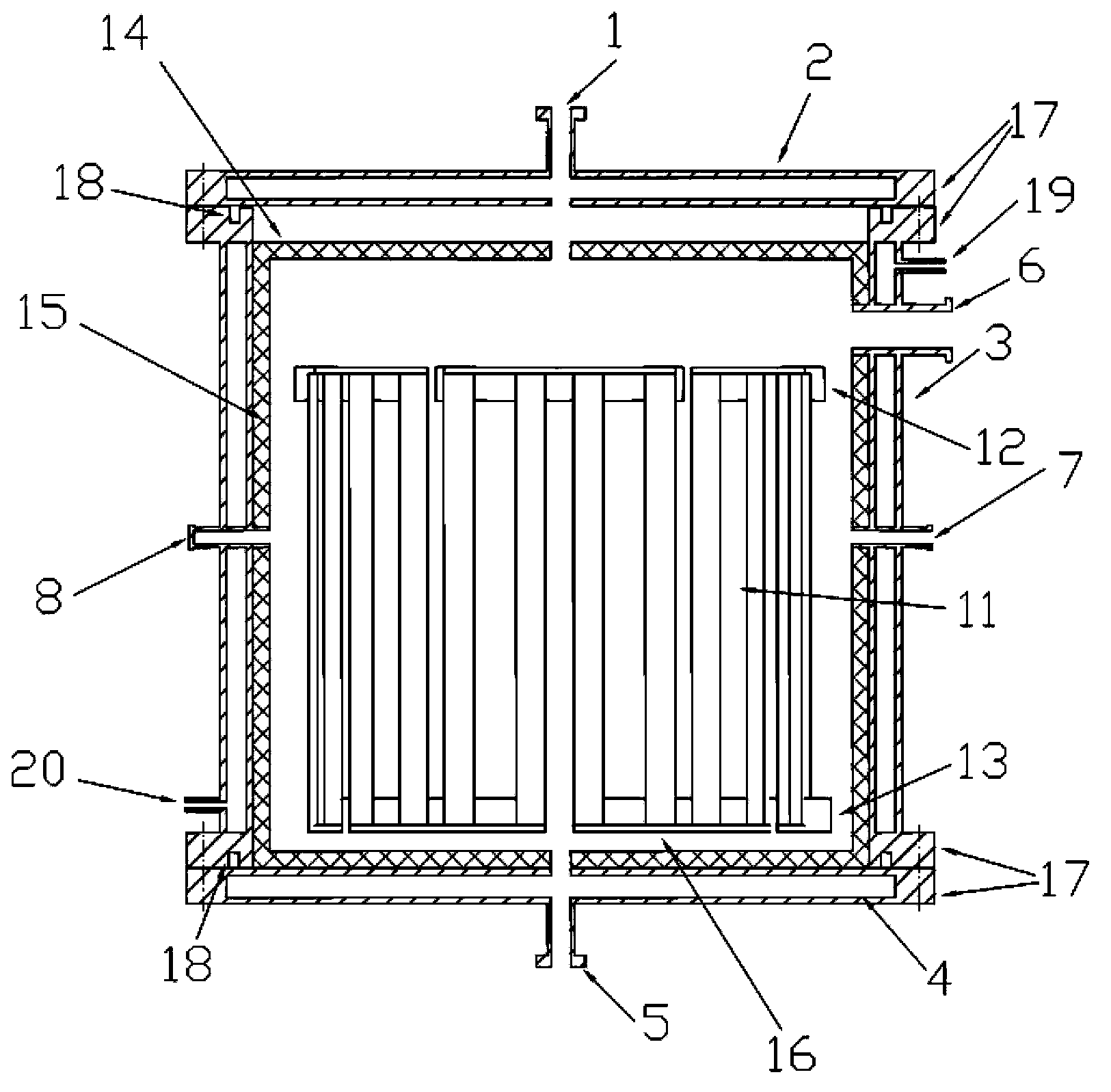

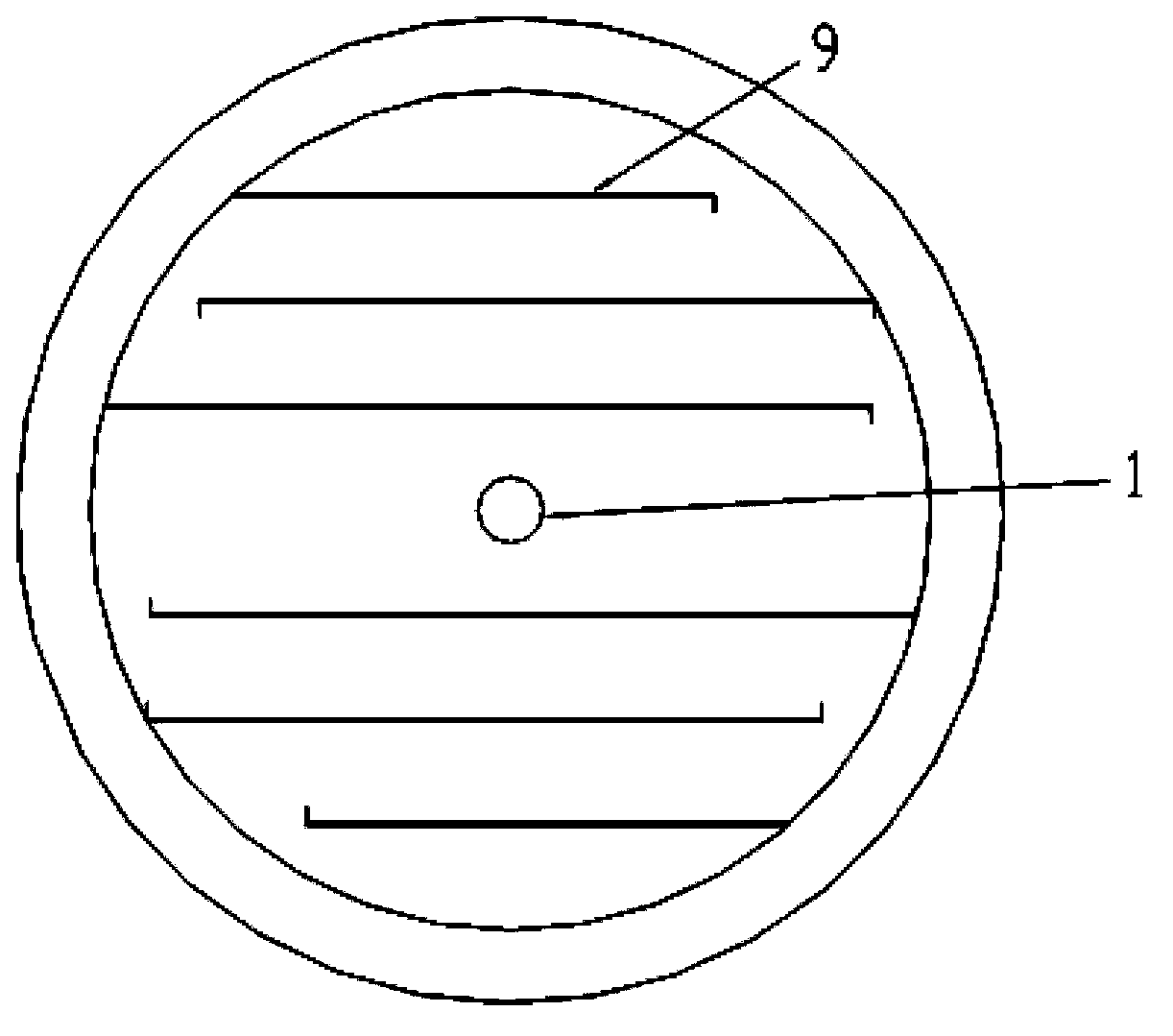

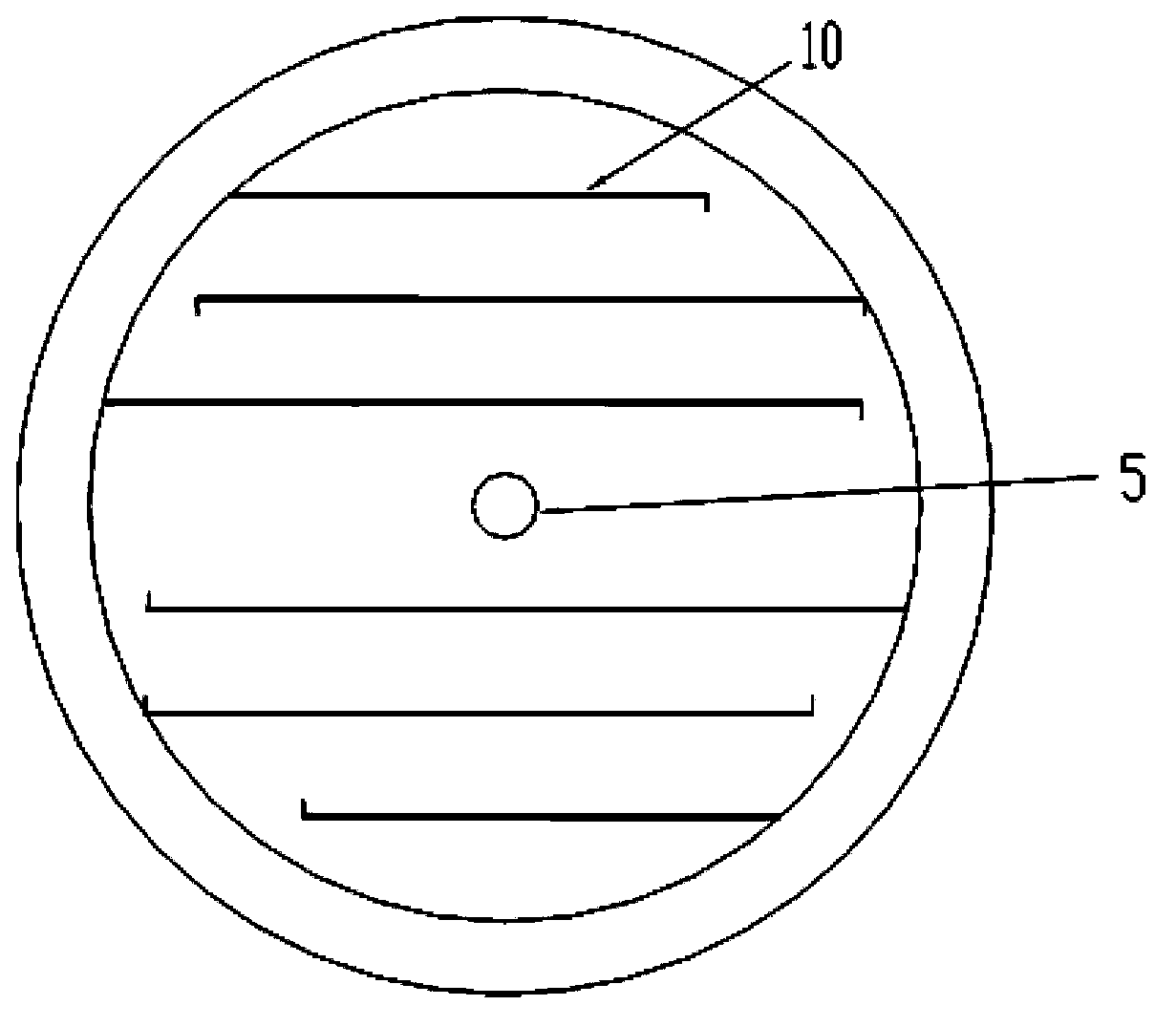

[0029] This embodiment is a device for heat treating PAN-based carbon felt, including an upper circulating water tank 2 , a furnace body 3 , a lower circulating water tank 4 , and a heating element 16 . Described body of heater has insulation layer 15, and upper insulation cover 14 is arranged on body of heater top. The heating element 16 is located in the furnace body and is supported on the furnace floor by high alumina bricks and electrodes. The upper circulating water tank 2 is placed on the upper surface of the upper insulation cover 14, and the lower circulating water tank 4 is located at the lower end of the body of heater 3, and is fixedly connected with the upper end and the lower end of the body of heater respectively by the flange 17. An insulating layer made of carbon felt is laid on the bottom plate of the furnace body. The upper part of the furnace body 3 has a furnace body exhaust port 6, and the furnace body 3 is connected with a vacuum system and a waste disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com