Domestic garbage fermenting container and device

A technology for fermentation container and domestic waste, applied in the field of domestic waste fermentation container and device, can solve the problem of restricting the resource utilization of organic decayable components to reduce the source of domestic waste, slowing down the heating rate of fresh materials, and being unable to be pulled out of the cylinder in time. It can solve the shortage of land resources, reduce the cost of garden maintenance, and improve the correct rate of garbage classification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

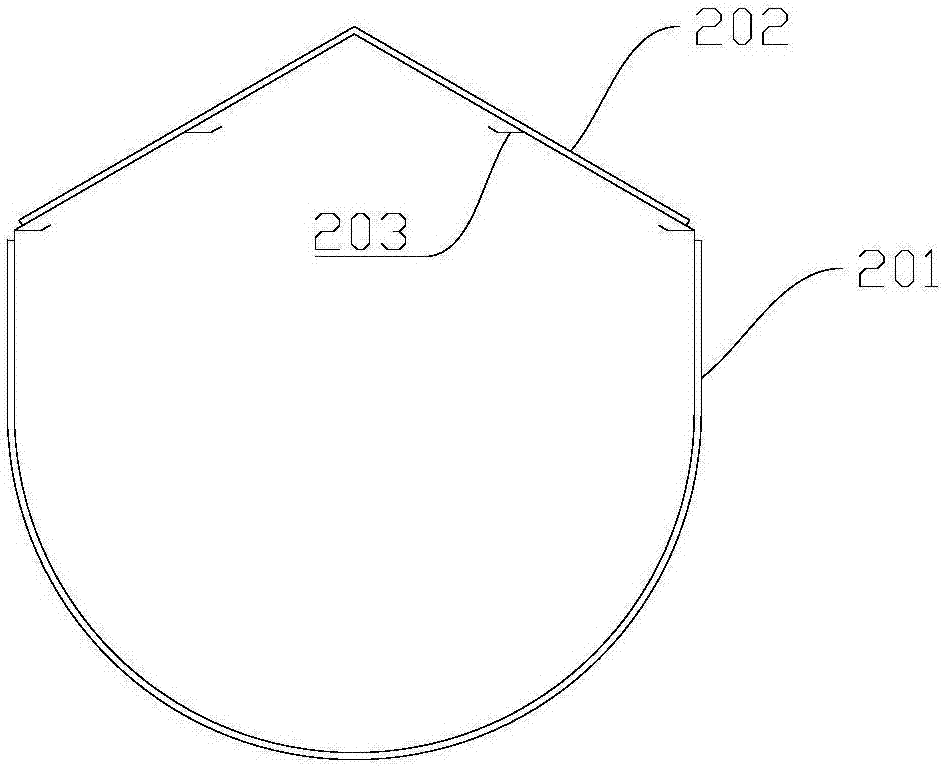

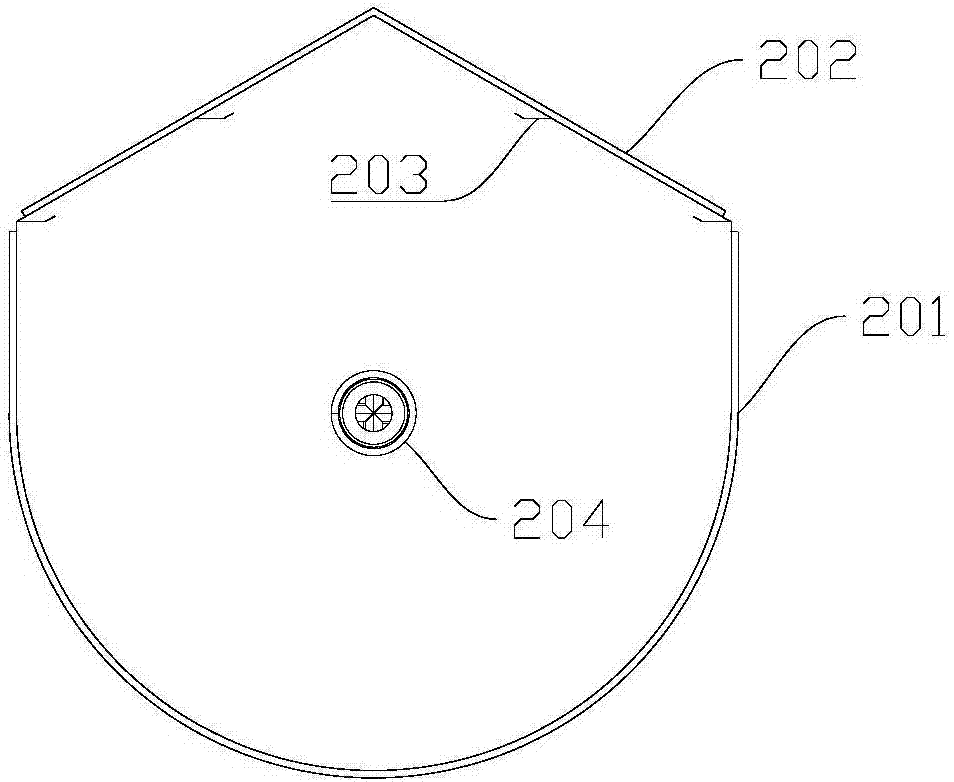

[0047] Such as Figure 5 and 6 As shown, an integrated domestic waste fermentation device, the main body of the device is located below the ground, and the structure for accommodating the main body of the device can be excavated in advance. The main body of the device includes a crusher 1, a fermentation container 2, a vibrating screen 4 and a feeding device, which are erected on a steel frame 10 as a whole, and the four corners of the frame 10 are respectively provided with hydraulic lifting rods 9 and 9 The bottom of the device is supported on the bottom surface of the underground structure containing the main body of the device, and is used to lift the main body of the device out of the ground. In the present embodiment, fermentation container 2 adopts figure 2 As shown in the structure, the diversion groove is used to collect the condensed water and the condensed water on the inclined surface during the fermentation process so that it does not flow back into the ferment...

Embodiment 2

[0062] In this embodiment, the main part of the integrated device is the same as that in Embodiment 1, but the trash can is optimized to increase the organic matter content of the garbage entering the integrated device. Such as Figure 7 and 8 As shown, in this embodiment, the bottom of the trash can 11 is provided with a pressure sensor 1103 for the weight of the garbage in the four sensing devices, and the device is provided with a color sensor for identifying the color of the garbage bag in the device and for sensing whether there is any garbage in the garbage. The metal magnetic roller 1105, the pressure sensor 1103, the color sensor and the magnetic roller 1105 are all connected to the control device for feedback control of opening and closing of the garbage outlet. The user can throw rubbish into the trash can by opening the lid 1101 , and can also take the rubbish away from the side opening 1102 .

[0063] The type of garbage can be identified through the color sensor...

Embodiment 3

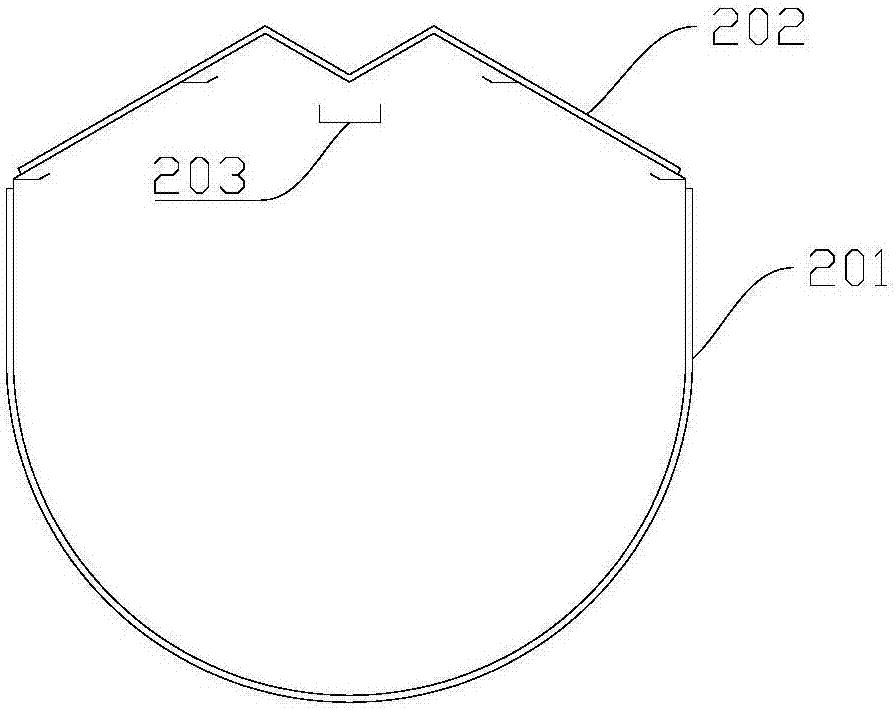

[0068] Compared with Embodiment 2, the difference of this embodiment is that the top of the fermentation vessel 2 cylinder is circular, and no condensate collecting device is provided, such as Figure 9 shown. The condensed water volatilized and condensed during the fermentation process is still returned to the fermentation material.

[0069] The key of the present invention is to crush domestic garbage in a crushing device and send it to a fermentation device for fermentation. After the fermentation product is sieved, the oversize is fed back to the crushing device to be crushed together with fresh domestic garbage. The integrated devices of the above three embodiments can all be used to ferment domestic waste without adding microbial agents and related conditioning agents. Below, the present invention combines the effect data of several experiments, so that those skilled in the art can more clearly understand the effects of the various improvements of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com