A temperature control method for semiconductor process equipment with feed-forward compensation

A technology of process equipment and feedforward compensation, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve problems such as contradictions and increased process time, and achieve improved temperature control performance, shortened heating time, and convenience The effect of setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

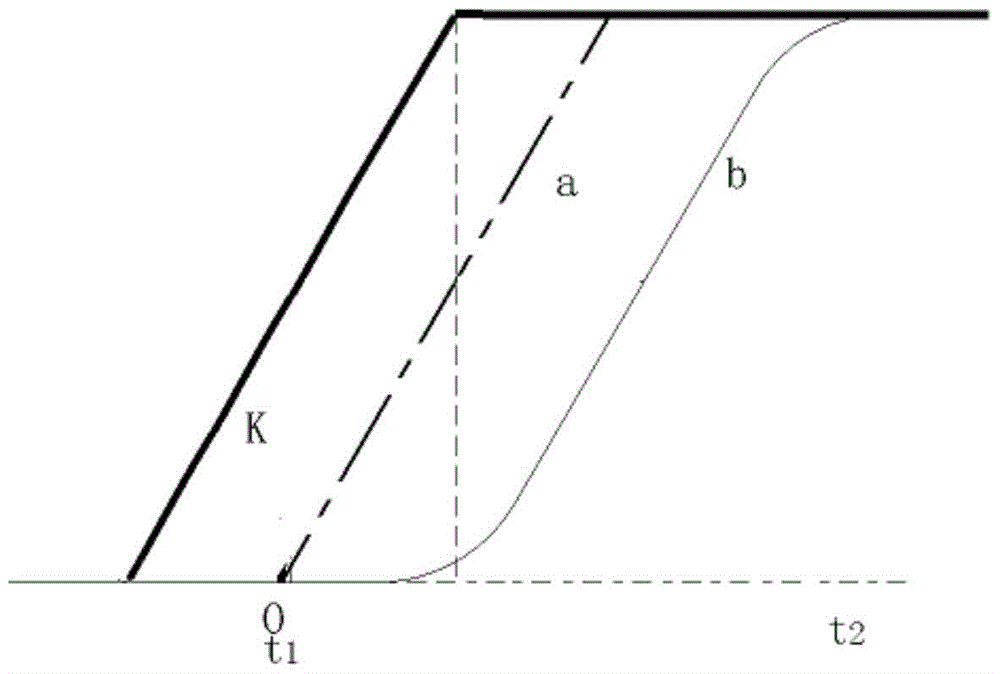

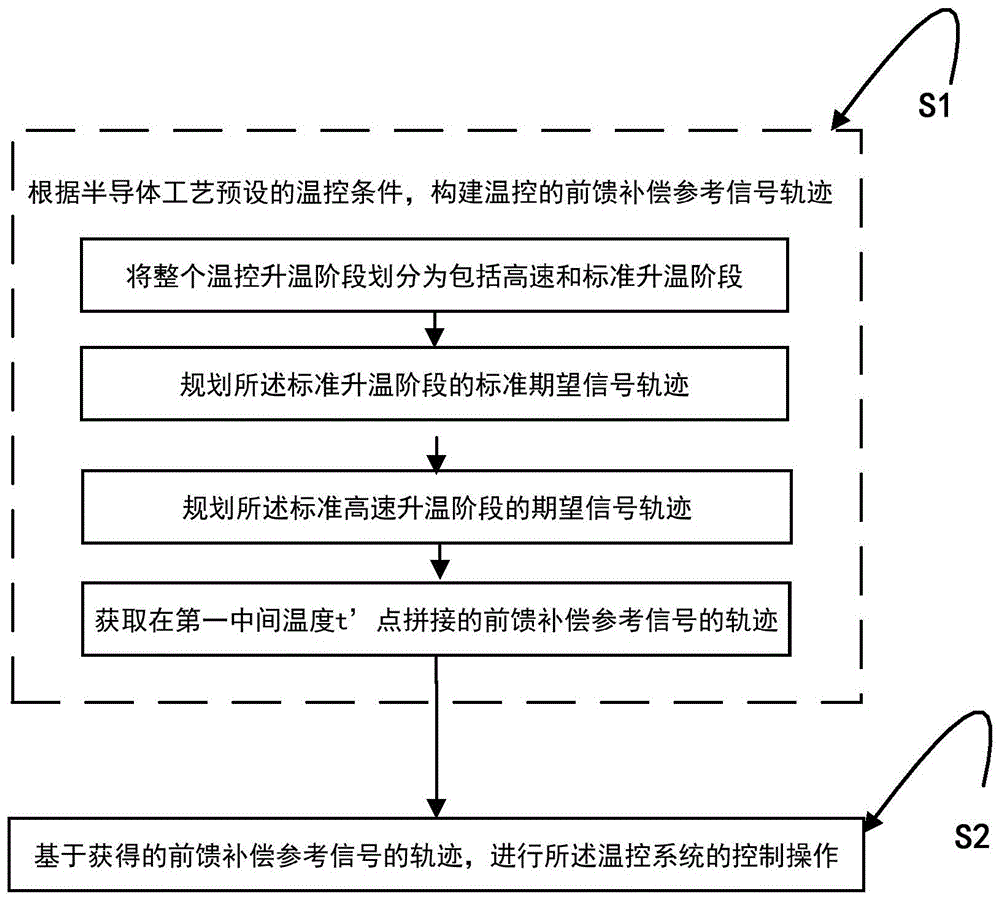

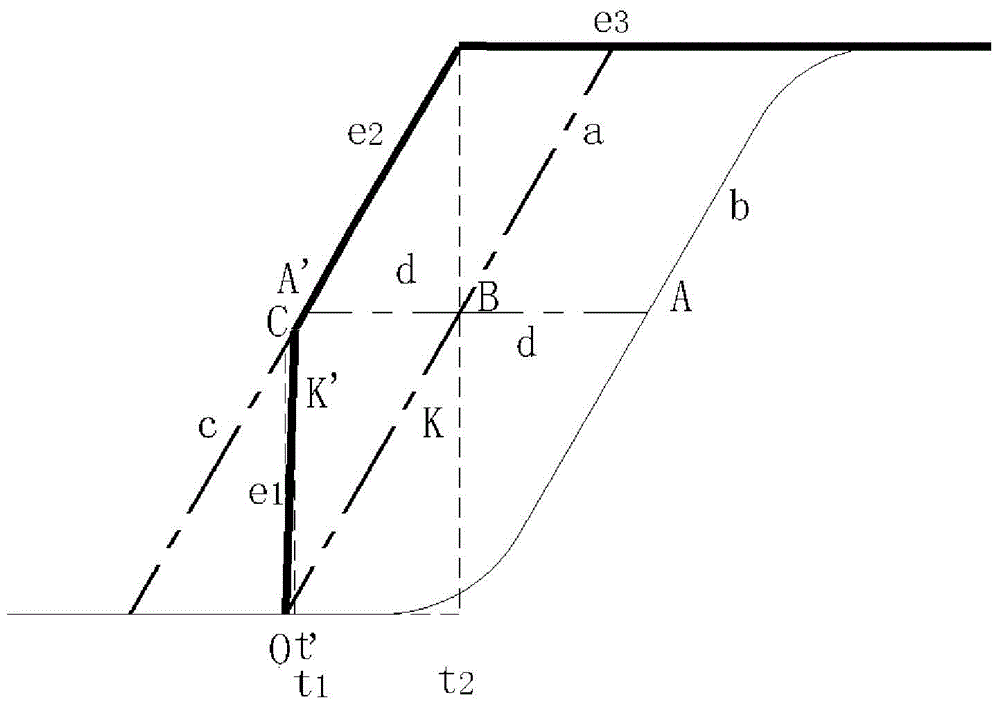

[0038] see image 3 , image 3 It is a schematic diagram of a preferred embodiment of the process of setting the feedforward reference signal trajectory in which the temperature rise control process is divided into a high-speed temperature rise stage and a standard temperature rise stage. Such as figure 2 and 3 As shown, step S1 can be specifically divided into the following steps:

[0039] Step S11: Divide the entire temperature-controlled heating-up phase into a high-speed heating-up phase T' and a standard heating-up phase T', and the high-speed heating-up phase T' completes the heating process from the initial temperature t to the first intermediate temperature t' (i.e. image 3 The heating process of the time period from 0 to t1 shown), the standard heating stage T completes the heating process from the first intermediate temperature t' to the target temperature T (that is, as image 3 The heating process of the time period from t1 to t2 shown).

[0040] It should be ...

Embodiment 2

[0049] In order to prevent the temperature control system from overshooting greatly during the temperature stabilization stage, in this embodiment, the method of the embodiment can be improved. Please combine figure 2 refer to Figure 4 , Figure 4 For the present invention will raise the temperature control process standard heating stage (that is as image 3 The shown temperature rise process from t1 to t2) is a schematic diagram of a preferred embodiment of the feedforward reference signal trajectory setting process which is further divided into the first temperature rise stage and the second temperature rise stage. Such as Figure 4 As shown, the standard heating period T includes the first heating period (ie, as Figure 4 The heating process of the time period from t1 to t2 shown) and the second heating stage (that is, as Figure 4 The heating process of the time period from t2 to t3 shown), the first heating stage completes the heating process from the first interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com