Rotary kiln for calcining refinery coke

A technology for calcining petroleum coke and rotary kiln, which is applied in the field of rotary kiln, and can solve the problems of no major improvement in the adaptability of the main technical level, poor physical and chemical indicators of calcined coke, and low operation rate of equipment, so as to achieve easy automatic control and benefit coke Effect of dust deposition and high operating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

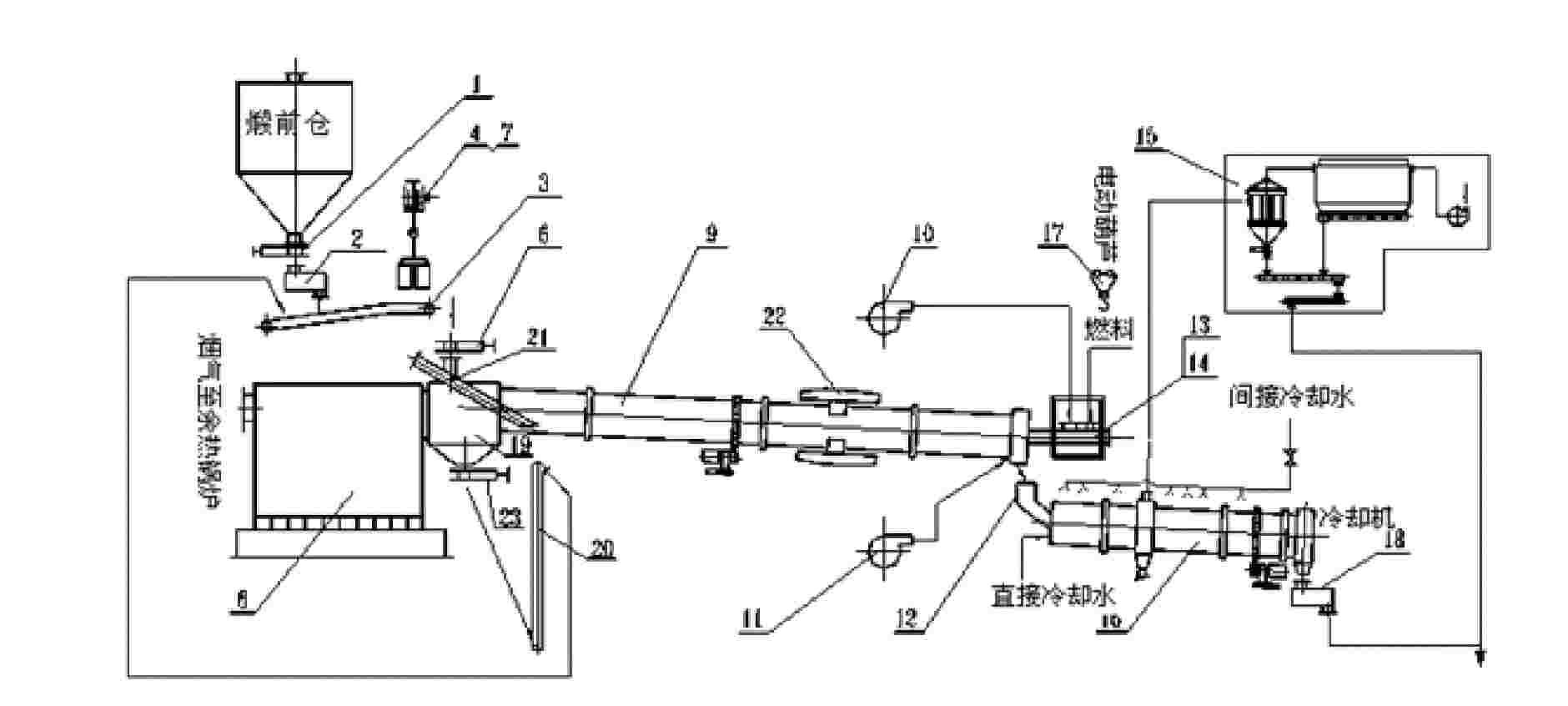

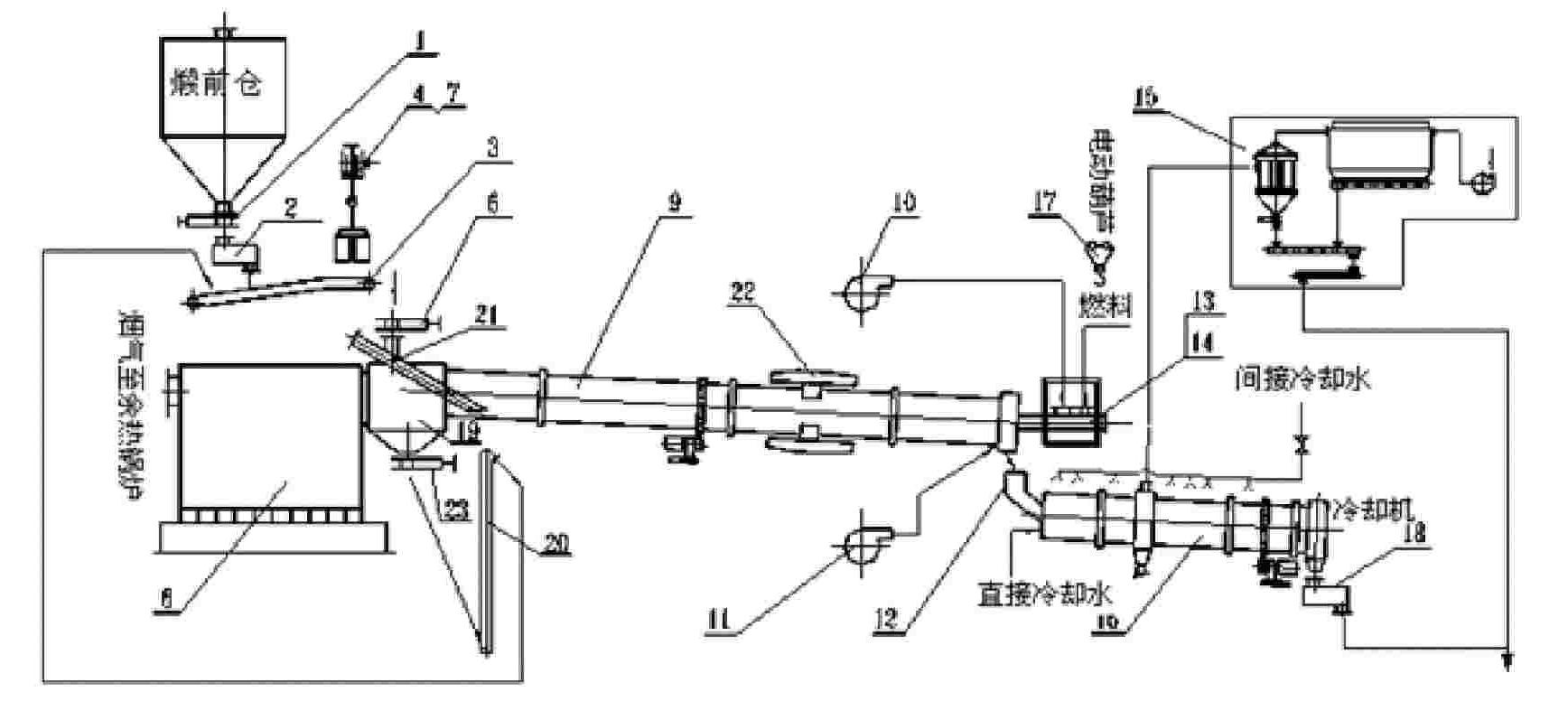

[0017] Embodiment of the present invention: open the lower gate valve 1 of the pre-calcined bin, and the raw materials stored in the pre-calcined bin are quantitatively fed to the belt conveyor 3 by the tape quantitative feeder 2, and then passed through the iron removal equipment 4 and 7. The flapper valve 6 and the obliquely inserted feed chute 21 are transported to the rotary kiln 9 for calcination, and the high-temperature dust-laden flue gas discharged from the tail of the rotary kiln passes through the transition section 19 of the rotary kiln 9 to settle fine coke particles and then enters the ash settling chamber 8. After settling a certain amount of coke dust and incompletely combusted volatile matter, it is fully burned and then sent to the waste heat boiler. The coke particles of fine particles settled and collected by the transition section 19 of the rotary kiln 9 enter the bucket elevator 20 through the gate valve 23 and then return to the belt conveyor 3 to enter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com