Primary baking process for increasing aroma richness of tobacco leaves

A richness, tobacco leaf technology, applied in the directions of tobacco, tobacco preparation, application, etc., can solve problems such as increasing the aroma richness of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. To increase the aroma richness of tobacco leaves and the initial roasting technology

[0025] Technical key: (1) Yellowing period, medium temperature and medium humidity combination, tobacco leaves gradually turn yellow; (2) Withering period, high temperature and high humidity combination, tobacco leaves moderately wither; (3) Color fixing period, cooling, humidification, slow Dry leaves; (4) During the dry gluten period, temperature control, suitable humidity, slow dry tendons.

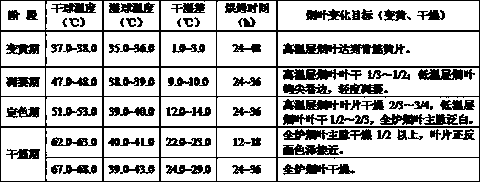

[0026] Taking the K326 variety and the smoking area at an altitude of 1500m to 1800m as an example, see Table 1.

[0027] Table 1 Primary curing process to increase the aroma richness of tobacco leaves

[0028]

[0029] Remarks: ①The temperature rise rate is 2°C / h to 37.0~38.0°C when the fire starts; the temperature rise rate between the subsequent stages is 1°C / h.

[0030] ②For high-temperature layer tobacco leaves, the air-flow descending curing barn refers to the top layer of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com