Method for improving proportion of residual manganese at end point of converter

A converter end point and ratio technology, which is applied in the manufacture of converters, etc., can solve the problems of reducing the reduction ratio in the middle period, weakening the difficulty and pressure of P removal, and shortening the transition time, so as to avoid phosphorus return, ensure the heating rate and temperature fullness, Guarantee the effect of slag melting heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1 provides a method for improving the ratio of residual manganese at the end of the converter, comprising the following steps:

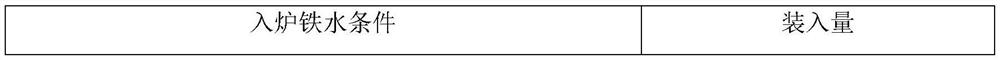

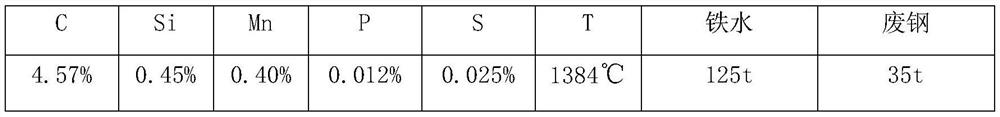

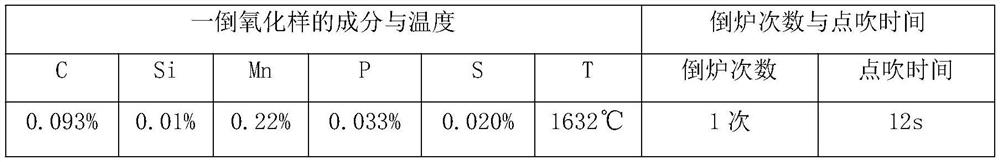

[0061] Under the process conditions of one tank to the end: the molten iron in the embodiment 1 and the charging amount are shown in the following table 1.1:

[0062] Into the furnace molten iron and charging amount in table 1.1 embodiment 1

[0063]

[0064]

[0065] The improvement and improvement of the whole process of blowing include the following steps:

[0066] (2.1) In the half-oxygen process, the mode of low molten iron ratio is selected, and the oxygen lance position is controlled at 1.3m after normal ignition;

[0067] (2.2) The full oxygen starts to increase the pressure first and then feed, adjust the oxygen pressure to 0.94MPa and the gun position 1.3m, strengthen the stirring of the molten pool, accelerate the preheating and melting of scrap steel, and ensure the heating rate and temperature fullness;

[0068]...

Embodiment 2

[0081] Embodiment 2 provides a method for improving the ratio of residual manganese at the end of the converter, comprising the following steps:

[0082] Under the process conditions of one tank to the end: the molten iron in the embodiment 2 and the charging amount are shown in the following table 2.1:

[0083] Into the furnace molten iron and charging amount in table 2.1 embodiment 2

[0084]

[0085] The improvement and improvement of the whole process of blowing include the following steps:

[0086] (2.1) In the half-oxygen process, the mode of low molten iron ratio is selected, and the oxygen lance position is controlled at 1.3m after normal ignition;

[0087] (2.2) The full oxygen starts to increase the pressure and then feed, adjust the oxygen pressure to 0.92Pa and the gun position 1.3m, strengthen the stirring of the molten pool, accelerate the preheating and melting of scrap steel, and ensure the heating rate and temperature fullness;

[0088] (2.3) When the ini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com