A kind of method for reducing tfe content in converter final slag

A technology of final slag and content, applied in the field of iron and steel metallurgy, can solve the problems of rising use cost of converter refractories, corrosion of furnace lining, poor effect of slag splashing to protect the furnace, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

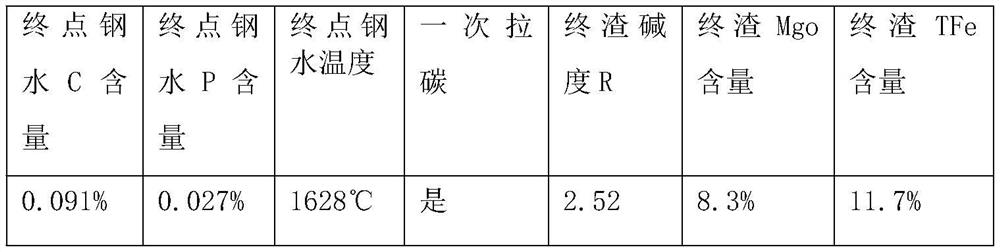

Embodiment 1

[0077] Embodiment 1 provides a method for reducing the TFe content in the final converter slag, comprising the following steps in sequence:

[0078] 1) The semi-oxygen automatic blowing mode is adopted 1.5 minutes before the dry dust removal and blowing. After the semi-oxygen is completed, according to the physical and chemical indicators of molten iron and scrap steel and the charging system, the oxygen supply operation with low gun position and high oxygen pressure is adopted to achieve the thermodynamics of slag removal. A benign match with dynamics;

[0079] The batch, amount and timing of adding slag-forming materials perform the slag-retaining operation in the converter blowing model;

[0080] In step 1), the oxygen supply operation using low gun position and high oxygen pressure is specifically: the low gun position is 1.1m, and the working oxygen pressure is ≥0.95Mpa;

[0081] 2) After blowing for 3.5min-4min, when the CO concentration curve slopes upward, carry out t...

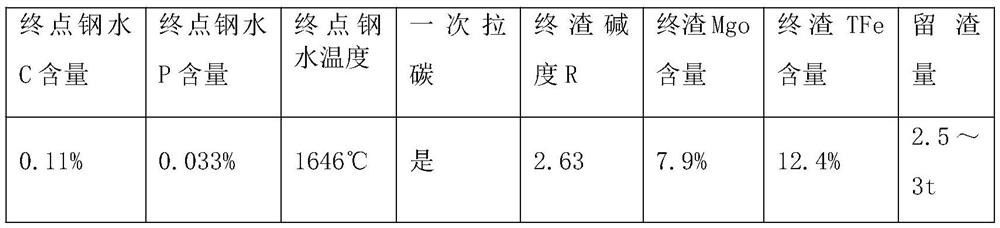

Embodiment 2

[0100] Embodiment 2 provides a method for reducing the TFe content in the converter final slag, comprising the following steps of performing in sequence:

[0101] 1) The semi-oxygen automatic blowing mode is adopted 1.5 minutes before the dry dust removal and blowing. After the semi-oxygen is completed, according to the physical and chemical indicators of molten iron and scrap steel and the charging system, the oxygen supply operation with low gun position and high oxygen pressure is adopted to achieve the thermodynamics of slag removal. A benign match with dynamics;

[0102] The batch, amount and timing of adding slag-forming materials perform the slag-retaining operation in the converter blowing model;

[0103] In step 1), the oxygen supply operation using low gun position and high oxygen pressure is specifically: the low gun position is 1.2m, and the working oxygen pressure is ≥ 0.95Mpa;

[0104] 2) After blowing for 3.5min-4min, when the CO concentration curve slopes upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com