Electrothermal heating maintenance device inside concrete

A technology of concrete and electric heating, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of unfavorable protection of human living environment, low thermal efficiency, slow construction, etc., and achieve the effects of avoiding defect repair costs, improving thermal efficiency, and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

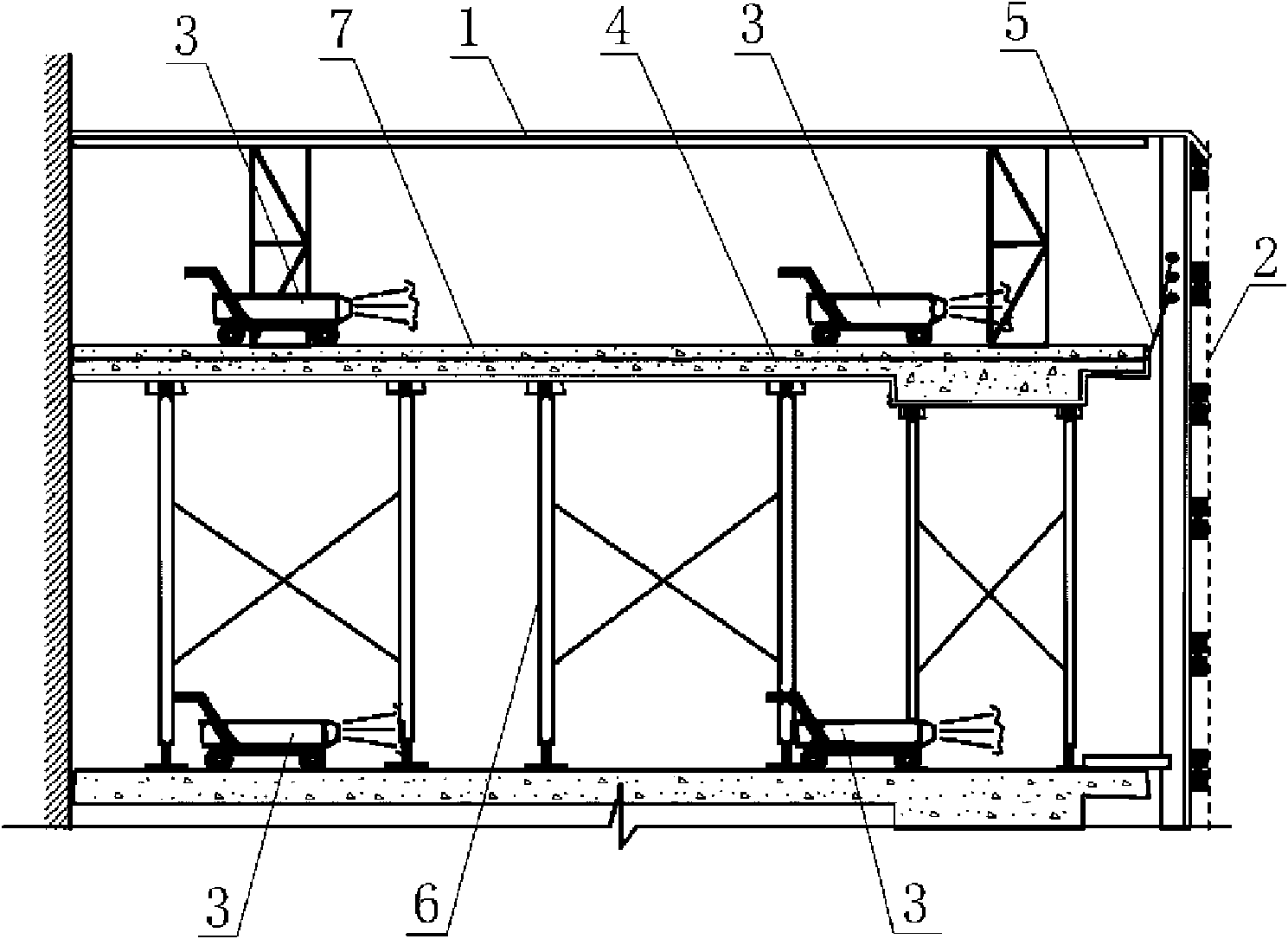

[0031] Examples see figure 1 As shown, this concrete internal electric heating maintenance device includes a closed greenhouse 1 on the top of the building under construction, a lifting protective frame 2 on the side of the building under construction and a preheating heater 3 inside the building under construction, It is characterized in that: the structural steel bars inside the concrete 7 of the building during construction are bound with heating resistance wires 4 , and the heating resistance wires 4 are connected to the power supply through the low-voltage power supply cables 5 outside the concrete 7 . see Figure 11 , The heating resistance wire 4 is connected to the low-voltage power supply cable 5 outside the concrete. In this embodiment, the low-voltage power supply cable 5 is a three-phase main cable.

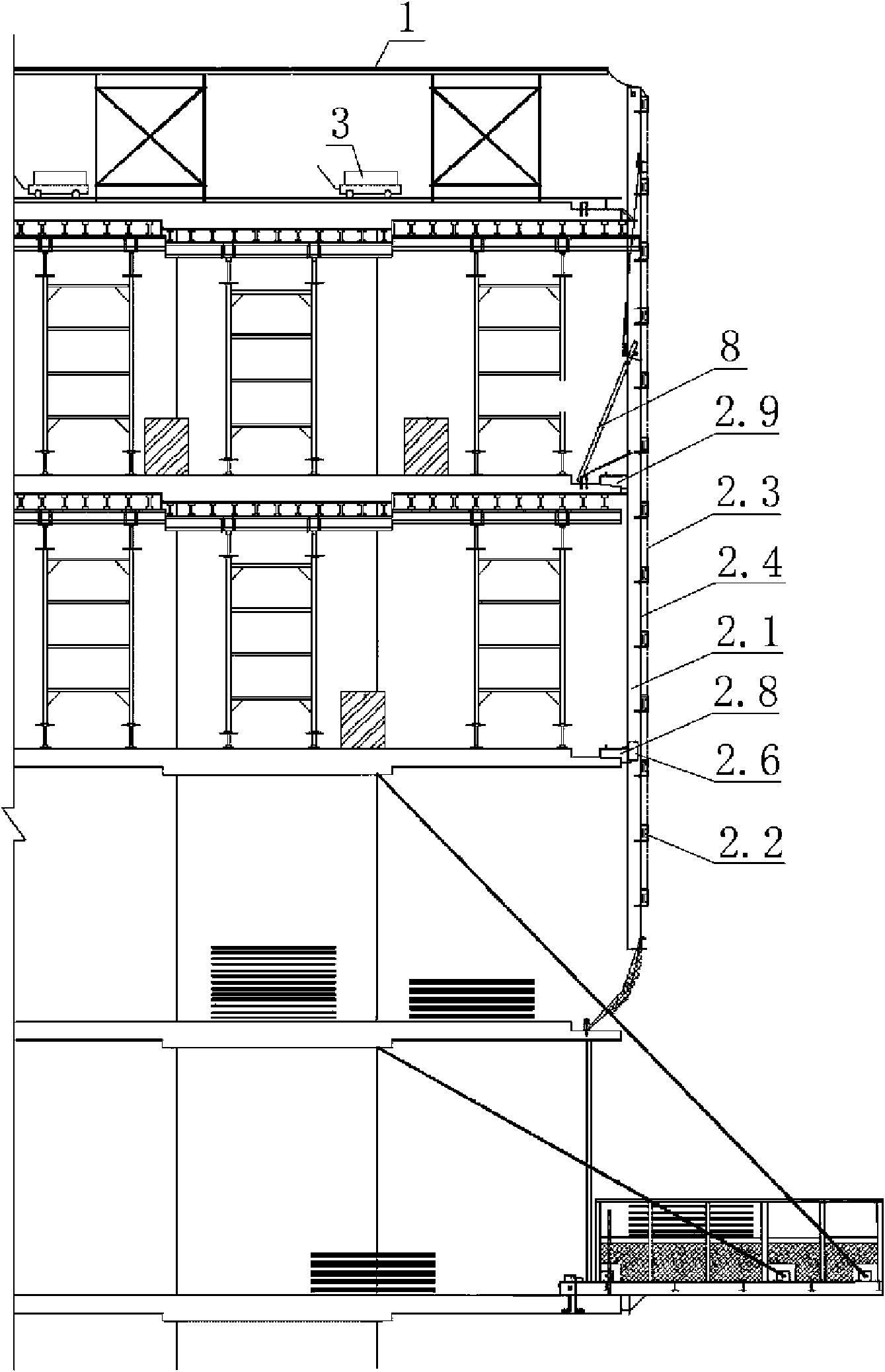

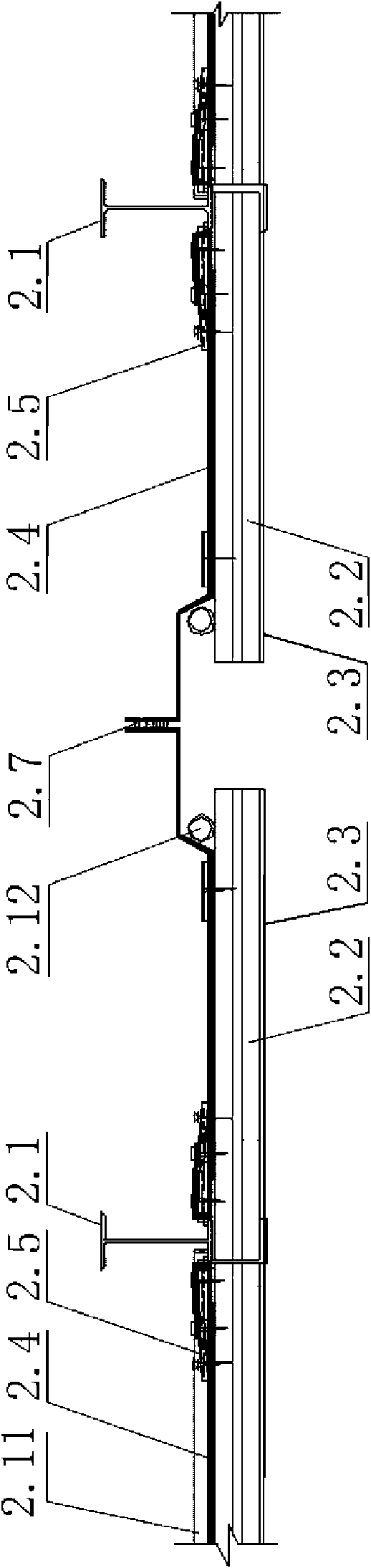

[0032] see Figure 2-9 , the lifting protective frame 2 includes a frame body and a safety net 2.3 attached to the frame body, the frame body is formed by cross-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com