Production process of laminated boards under low-temperature condition

A technology of production technology and low temperature conditions, applied in the field of laminated slab production technology under low temperature conditions, can solve problems such as temperature cracks on the surface of laminated slabs, affect the quality of laminated slab molding, and large temperature differences between inside and outside of concrete, so as to avoid temperature cracks and save repairs Work, alleviate the effect of temperature cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

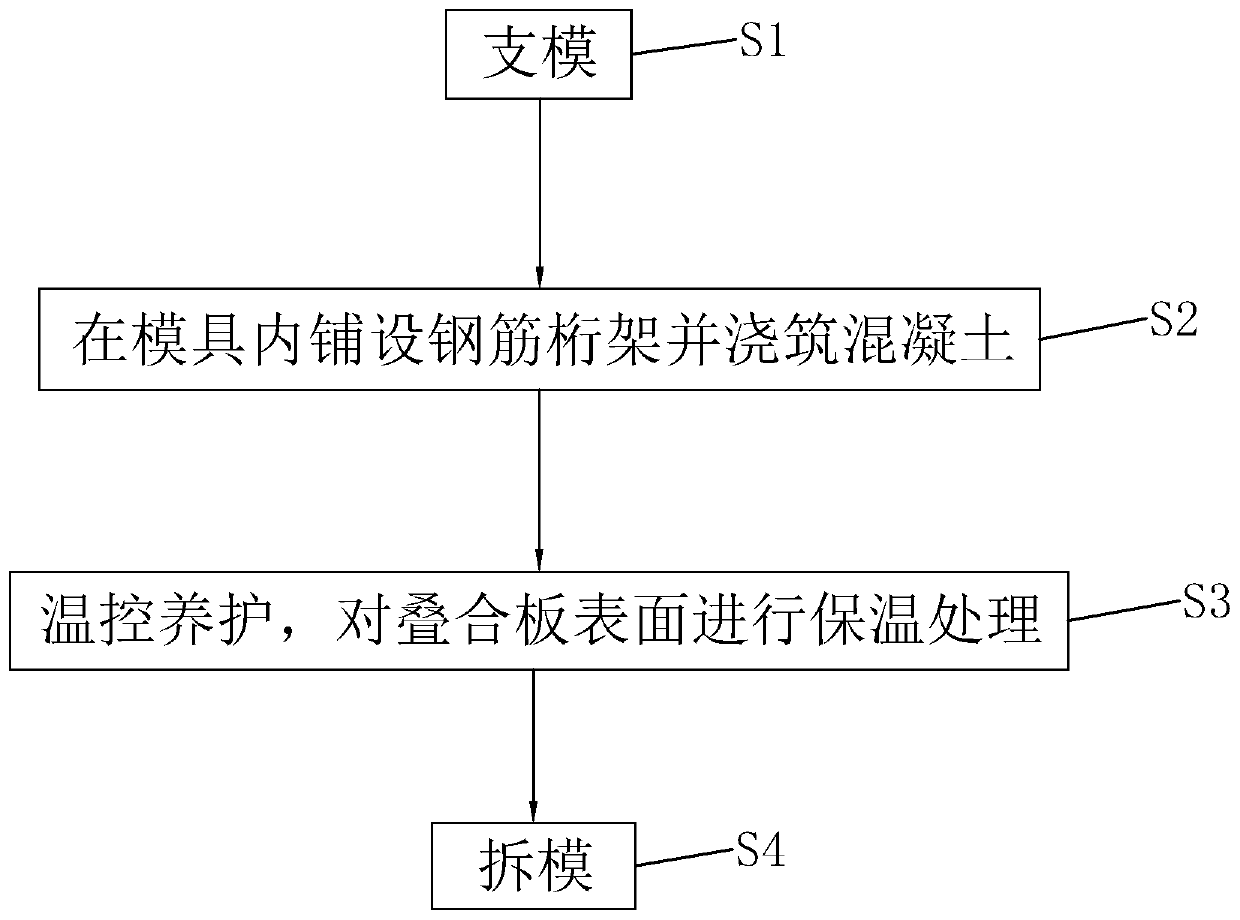

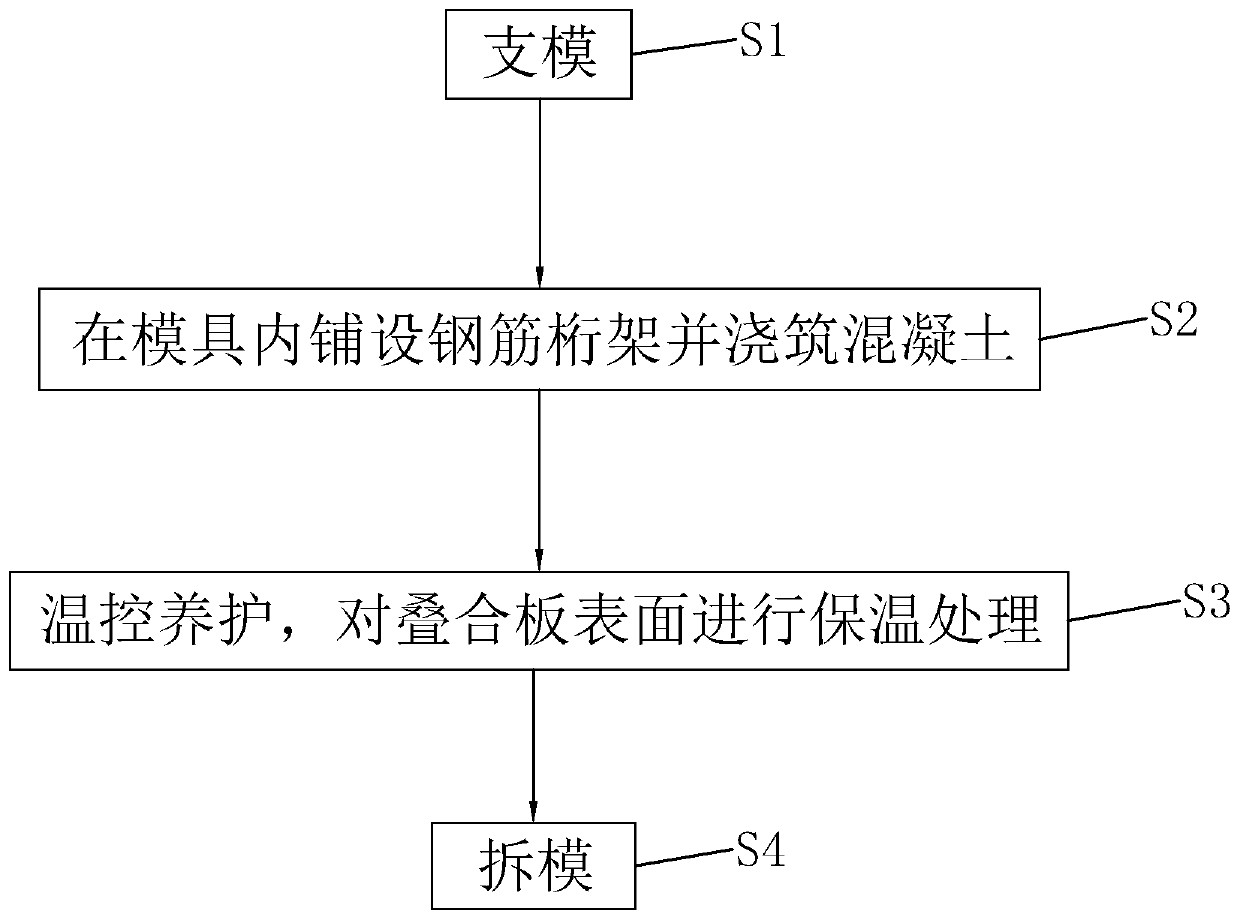

[0031] See attached figure 1 , a laminated board production process under low temperature conditions, which can overcome the problem that laminated boards are prone to temperature cracks in low temperature environments, and includes the following steps:

[0032] S1, formwork support. In normal production, the entire pouring operation of the laminated slab can be completed on the steel platform; before pouring, the formwork is supported on the steel platform, and the corresponding pouring mold is fixed on the steel platform, and the pouring mold is surrounded by a square frame structure as a whole , the pouring area for pouring the formed laminated slab is formed inside.

[0033] S2. Laying steel bar trusses and pouring concrete in the mould. After the form support is completed, several steel bar trusses can be laid in the mold first, and the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com