Method for taking cooling pipe network as building bottom plate multi-layer reinforced support frame

A technology of cooling pipes and support frames, which is applied in the processing of building materials, construction, building construction, etc. It can solve the problems of difficult control of the quality of on-site butt joints of steel pipe columns, high requirements for hoisting precision of steel pipe columns, and difficulties in thermal insulation and maintenance of ground beams. Achieve the effect of convenient and quick dismantling, ensure the quality of pouring, and avoid the sinking of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

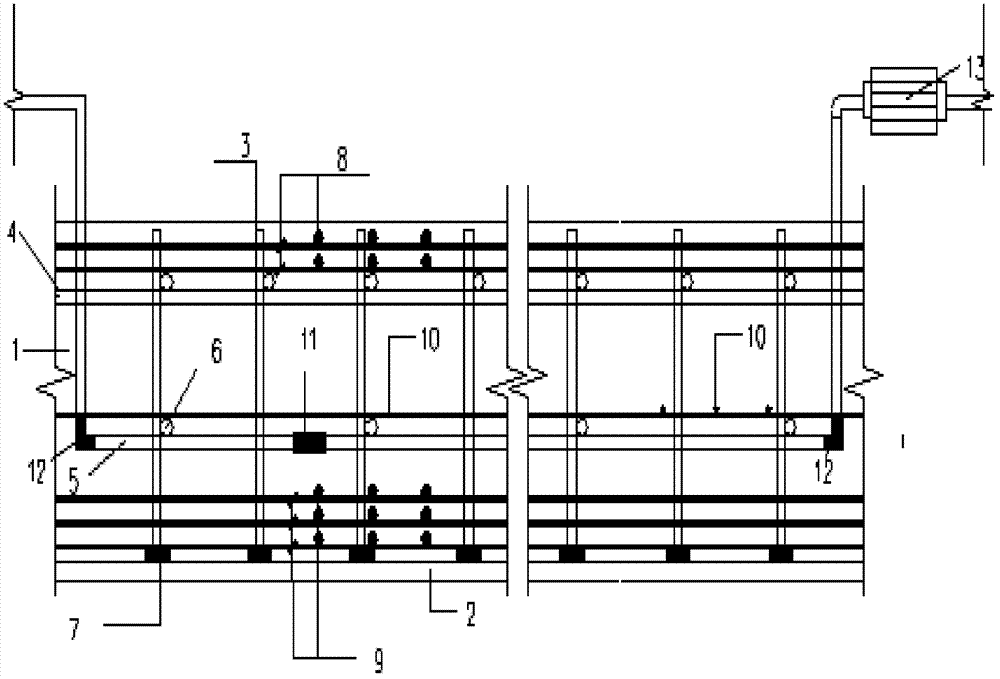

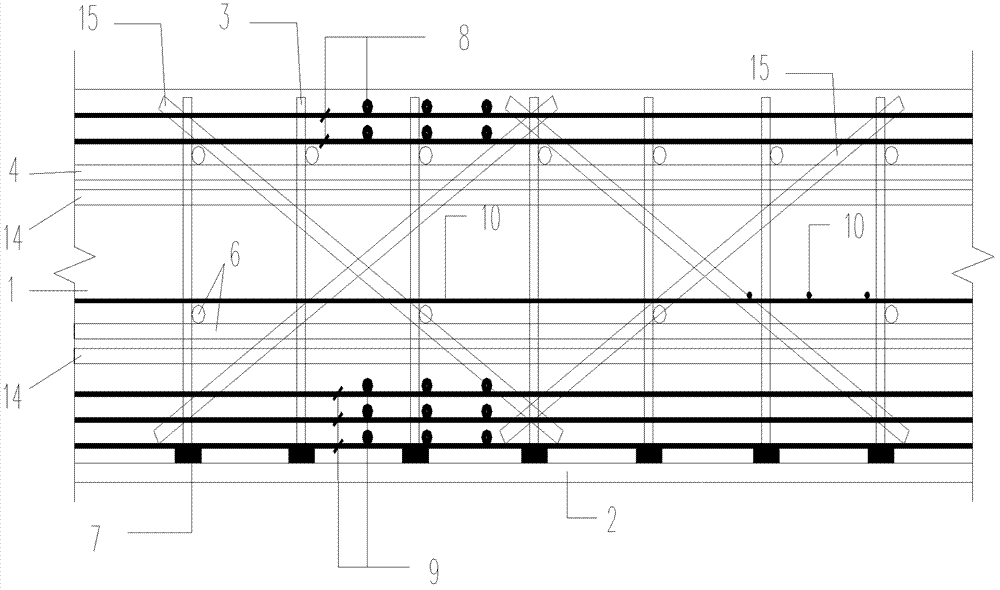

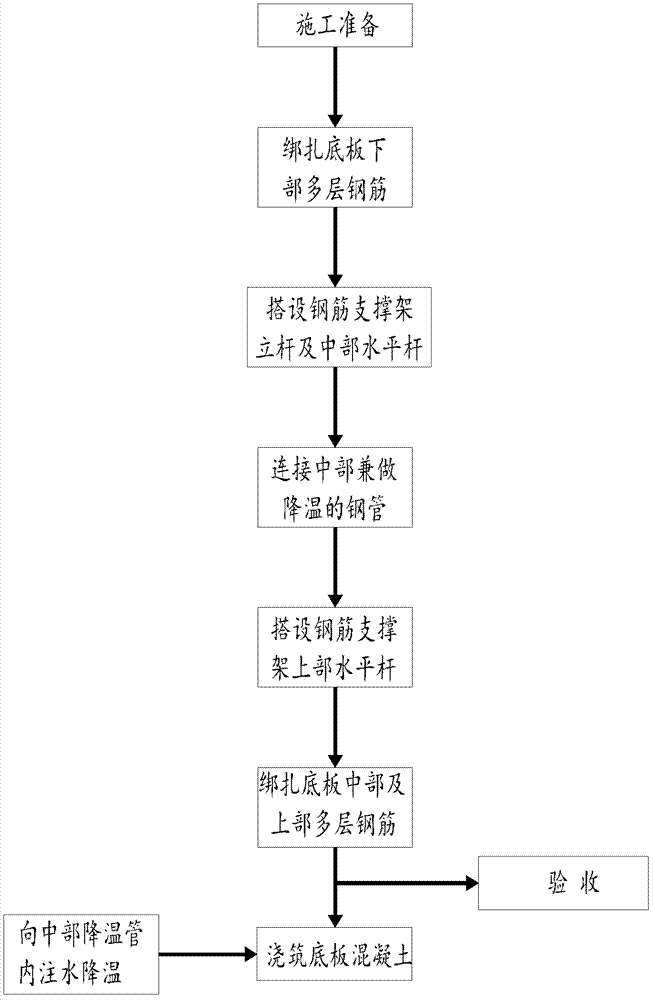

[0012] refer to figure 1 , figure 2 . In the cooling steel pipe network support system for the construction of multi-layer steel bars on a large-volume concrete floor described below, the fastener steel pipe frame is erected on the concrete floor 1 . Connect vertical rod 3 steel pipes and horizontal rod steel pipes with fasteners, base plate middle part reinforcement 10, base plate top reinforcement 8 are bound on the middle part horizontal rod 6 and the upper horizontal rod 4 of fastener steel pipe frame respectively. The middle horizontal rods 6 arranged in a line or matrix in the middle of the fastener steel frame are connected by quick connectors to form a closed pipe. The fastener steel pipe frame starts from the edge of the raft bottom plate to set up steel pipe supports to support the middle steel bar 10 and the upper steel bar 8 of the concrete bottom plate. After binding the steel bars of the concrete floor, use fastener steel pipes to set up steel pipe supports f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com