High-temperature retarding and water reducing agent

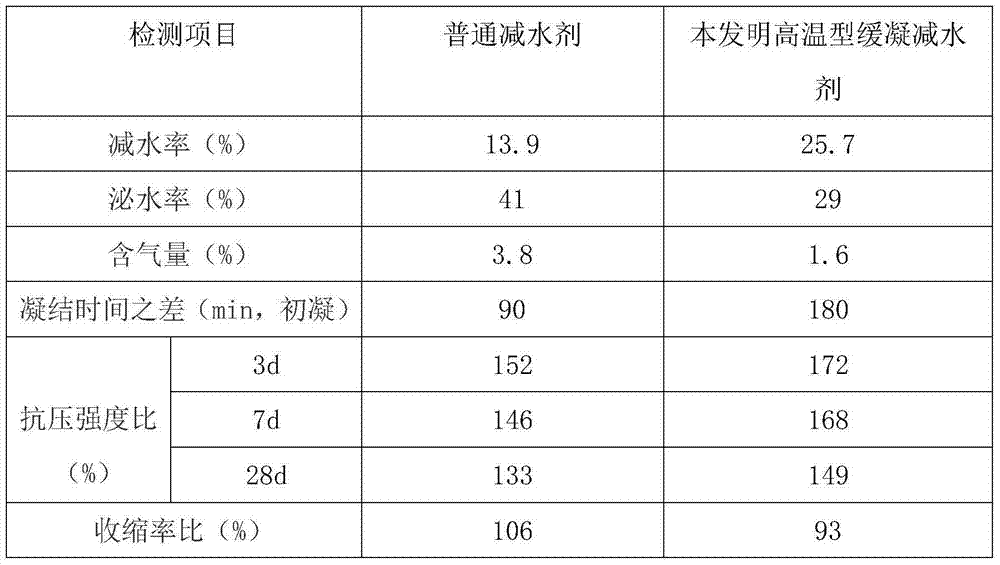

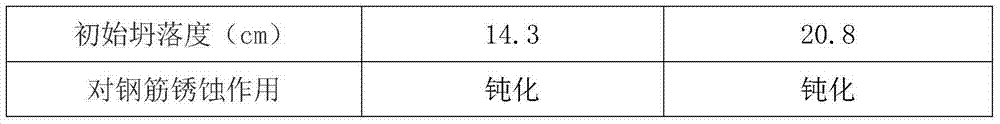

A retarding water reducer and high temperature technology, applied in the field of concrete admixtures, can solve the problems of insufficient high temperature resistance and inability to meet the needs of high temperature and high pressure cementing construction, and achieve good slump retention, significant water reduction and enhancement effects, and broad The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A high-temperature retarding water reducer, which is made by mixing the following raw materials by weight (kg): polycyclic aromatic hydrocarbon sulfonate formaldehyde condensate 35-45, aliphatic hydroxyl sulfonate condensate 20-30, diethylenetri Aminopentamethylenephosphonic acid 10-15, sugar calcium 8-16, alum stone powder 12-18, xanthan gum powder 5-10, barium metaborate 4-8, sodium lauryl sulfate 3-6, pentaerythritol distearate Esters 2-4, maleic anhydride-styrene sulfonic acid copolymer 6-12, blast furnace slag powder 10-15, waste sugar slag powder 5-10, pull-off powder 7-13, additives 4-7;

[0011] The auxiliary agent is made of the following raw materials in parts by weight: 10-15 parts by weight of magnesite, 3-6 parts of magnesium humate, 2-4 parts of ammonium benzoate, 6-12 parts of sodium α-alkenyl sulfonate, 6-12 parts of inositol Phosphate ester 1.5-2.5, isobutylene triethoxysilane 3-5, polyferric chloride 5-10, germanite powder 12-18, titanium dioxide 5-10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com