Two-sided welding method for U-shaped ribbed slab unit welding seam

A rib and fillet weld technology is applied in the field of double-sided welding of U-rib unit welds, which can solve the problems of fatigue cracking of orthotropic steel bridge decks, unreasonable weld forms, and large bending stress. Extremely low risk of weld cracks, avoidance of arc breaks, reduced stress amplitude effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

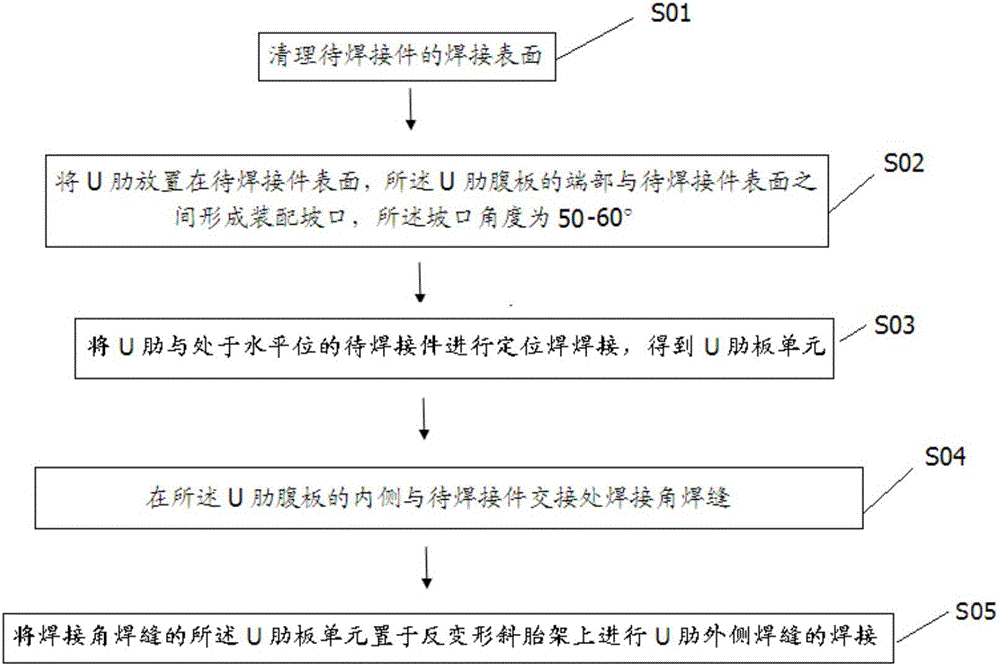

[0051] Embodiment 1 of the present invention is used for the double-sided welding method of U-rib unit welds, including the following steps:

[0052] S101. Polish and clean the rust, oil stain, paint and oxide skin on the area to be welded on the upper end surface of the bridge deck and within the range of 20-30 mm on both sides, so as to expose the metallic luster;

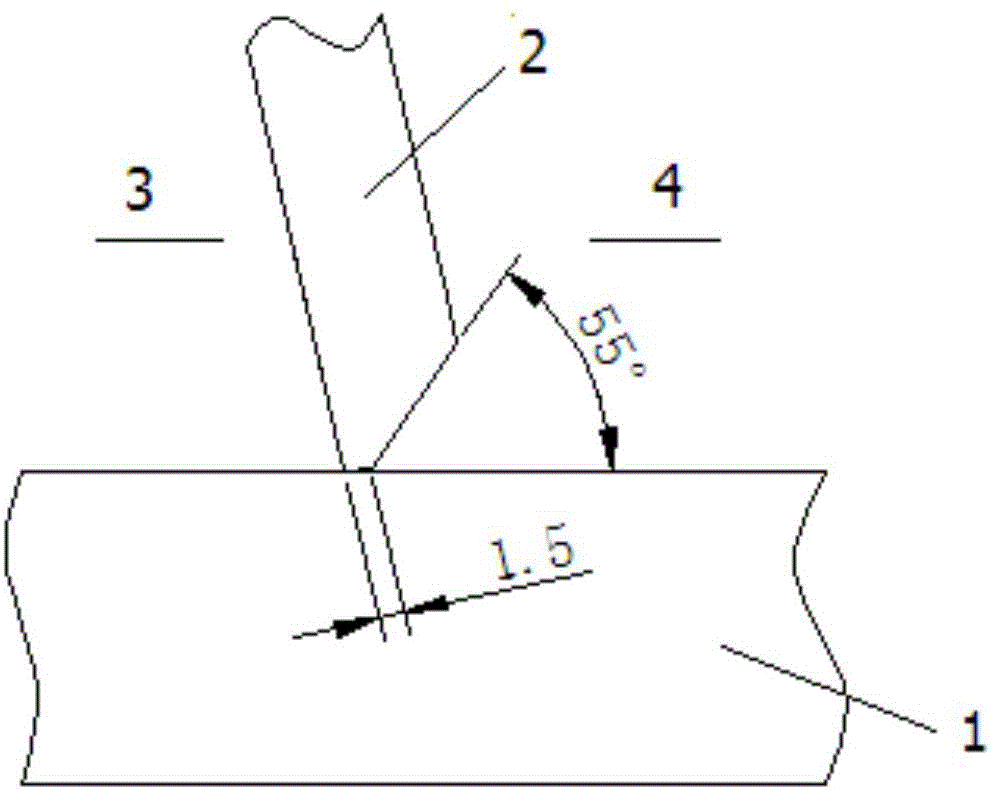

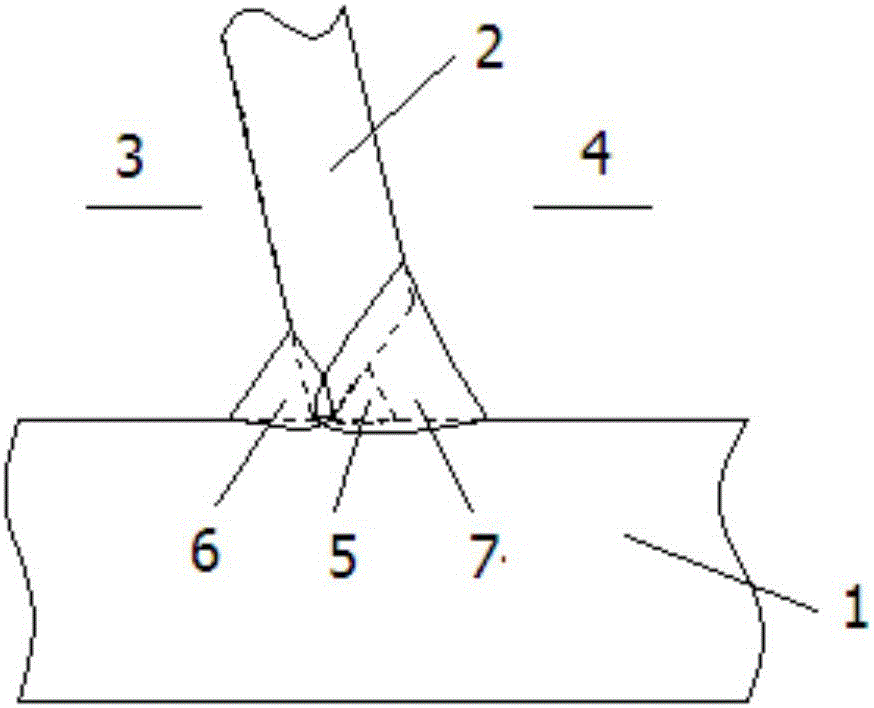

[0053] S102. Put the U rib upside down on the bridge deck. At this time, an assembly groove is formed between the bottom end of the U rib and the upper surface of the bridge deck. The angle of the groove is 55°, and the blunt edge of the assembly groove is 1-2 mm. The assembly gap between the U-rib and the bridge deck is 0-0.75mm; figure 2 Shown is a schematic diagram of the assembly groove formed between the U-rib and the bridge deck in Embodiment 1 of the present invention.

[0054] S103, performing tack welding on the U-rib and the bridge deck in the horizontal position to obtain a U-rib unit, the tack weldi...

Embodiment 2

[0059] Embodiment 2 of the present invention is used for the double-side welding method of U-rib unit welds, including the following steps:

[0060] S201. Polishing and cleaning the area to be welded on the upper end surface of the orthotropic steel bridge deck and the rust, oil stains, paint and scale within the range of 20 to 30 mm on both sides, so as to expose the metallic luster;

[0061] S202. Place the U rib upside down on the orthotropic steel bridge deck. At this time, an assembly groove is formed between the bottom end of the U rib and the upper surface of the orthotropic steel bridge deck. The blunt edge of the groove is about 1.5mm, and the groove angle is about 60°, and the assembly gap between the U-rib and the orthotropic steel bridge deck is 0-0.75mm;

[0062] S203, using a solid welding wire to perform tack welding on the horizontal orthotropic steel bridge deck, the tack welding spacing is 300-400 mm, the tack welding length is 40-50 mm, and the tack welding ...

Embodiment 3

[0067] Embodiment 3 of the present invention is used for the double-side welding method of the U-rib unit weld seam is similar to Embodiment 2, the difference is that: the piece to be welded is a steel box girder bottom plate, the groove angle is 50°, and the tack welding in step 3 Using CO 2 Gas shielded welding, during step 4 fillet weld welding, adopt ternary mixed gas shielded welding, the mixed gas includes Ar, CO 2 and O 2 . The volume ratio of each component of the mixed gas is: Ar is 84%, CO 2 14%, O 2 2%. When the fillet weld is welded, the welding current is 270-290A, the arc voltage is 30-32V, and the welding speed is 360-400mm / min.

[0068] There is only a very small amount of silicon oxide slag on the surface of the solid wire gas shielded welding seam, which does not affect the online video monitoring of the appearance of the fillet weld inside the U rib. In addition, the ternary gas mixture (Ar+CO 2 +O 2 ) protection, the gas flow rate is 18 ~ 22L / min, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com