Novel multi-wave metal engine cylinder cover sealing gasket

A technology for engine cylinders and sealing gaskets, which is applied in the direction of engine sealing devices, engine components, machines/engines, etc., and can solve problems such as fatigue damage and affecting sealing performance, so as to prevent fatigue damage, improve air sealing performance, and reduce stress The effect of amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

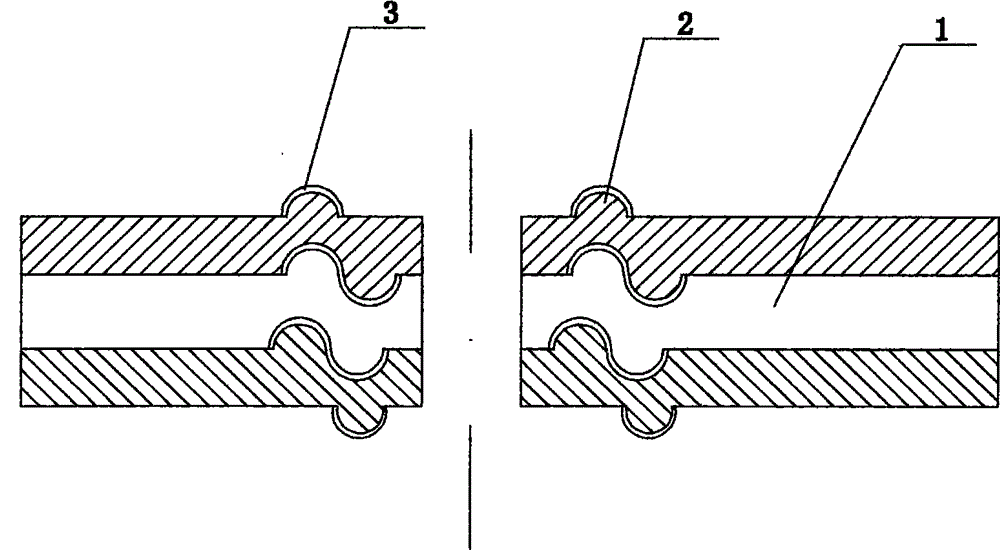

[0009] see figure 1 , the specific embodiment adopts the following technical scheme: it includes a gasket body 1, a corrugation 2, and a locking device 3; the corrugation 2 is arranged on the edge of the cylinder mouth of the gasket body 1, and the corrugation 2 is provided with a locking device 3 , the width of the corrugated 2 is 0.5-1.0mm, the height is 0.1-0.2mm, and the thickness of the locking device 3 is 0.05-0.1mm.

[0010] The gasket body 1 uses a high-strength, high-hardness, and high-elasticity stainless steel cold-rolled plate or an alloy carbon steel sheet as a base material.

[0011] The specific embodiment has the following beneficial effects: it reduces the stress amplitude in the vertical direction of the cylinder head gasket when the engine is running, prevents the fatigue damage of the elastic gasket, and improves the high temperature and high pressure air sealing performance of the cylinder head part of the cylinder head gasket.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com