Center supported bond joint

a center support and bonding technology, applied in the direction of auxillary welding devices, soldering apparatus, ways, etc., can solve the problems of weaker bonded rail joint bars b>30/b> with less electrical insulation capability, and high price of non-metallic rail joint bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

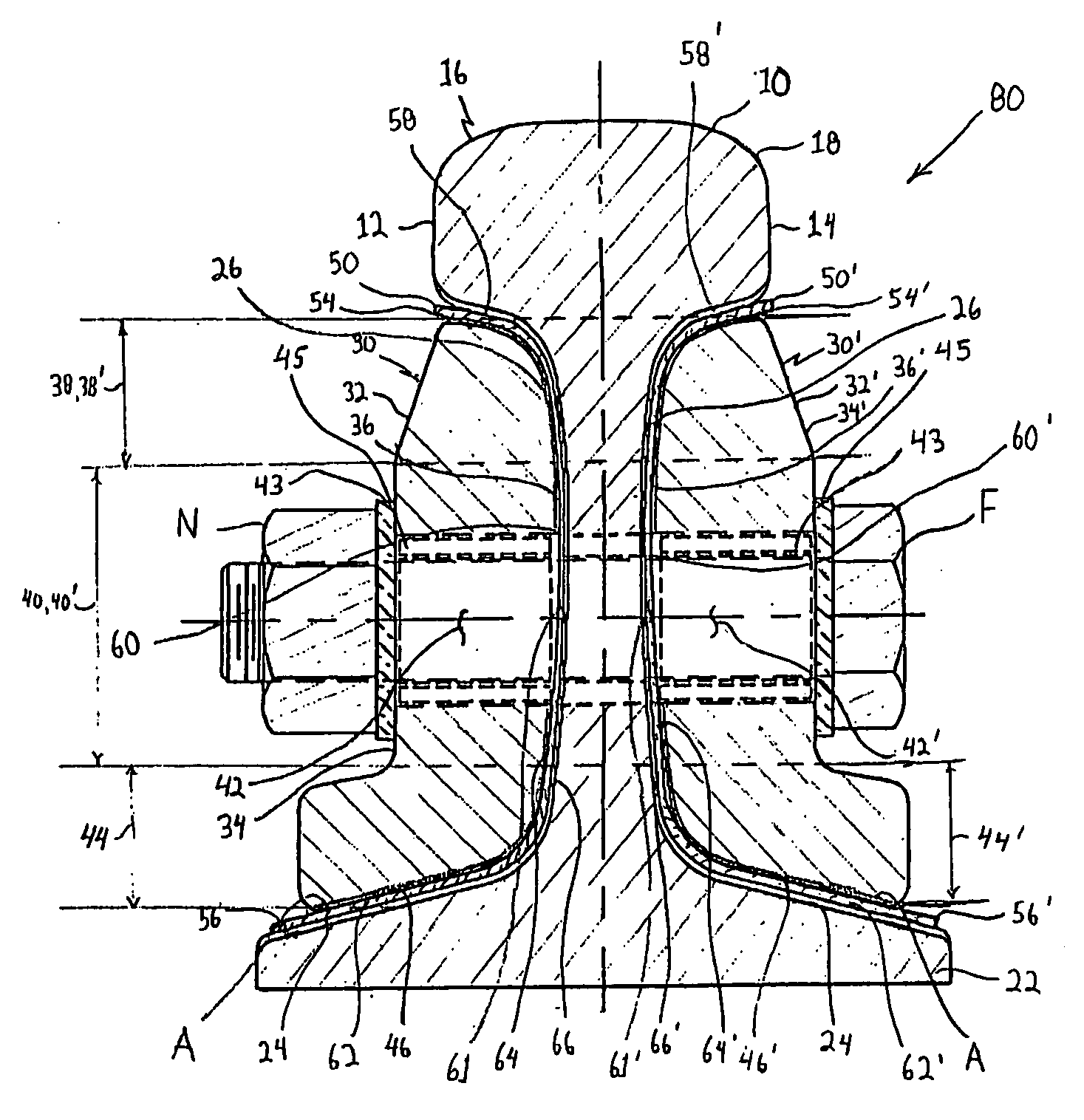

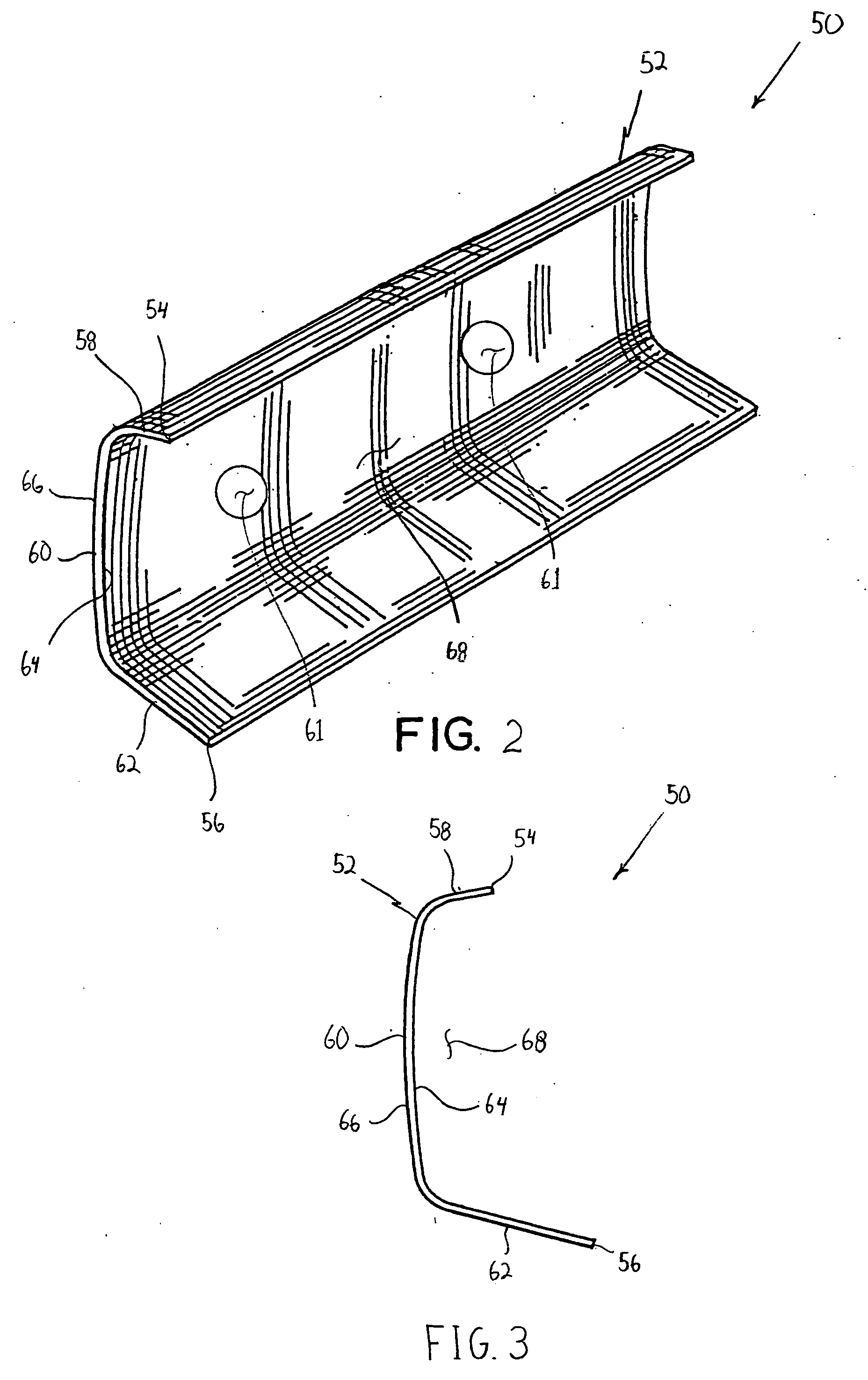

[0023] Referring to FIGS. 2-4, the present invention provides a center support sleeve 50 that is adapted to be sandwiched between a center portion of a prior art rail joint bar 30 and a pair of railroad rails 10, 10′ (designated as area A1 shown in FIG. 8). The support sleeve 50 extends partially around the rail joint bar 30 as shown in FIG. 4 in order to spread the impact loads of the rail cars away from the center portion of the rail joint bar 30. The sleeve 50, which has an end profile similar to the back surface 36 of the prior art rail joint bar 30 includes a body 52 having a first end 54 and a second end 56 and defining a head portion 58, a web portion 60 and a base portion 62. The body 52 of the sleeve 50 includes a first surface 64 and a second surface 66, wherein the head portion 58 depends from the web portion 60, which depends from the base portion 62. The head portion 58 and the base portion 62 are bent in a direction toward the first surface 64 of the web portion 60, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com