Sealed environmental cabin for power assembly temperature experiment of pure electric vehicle

A powertrain, temperature test technology, used in vehicle testing, environmental/reliability testing, machine/structural component testing, etc. Large error and other problems, to achieve the effect of true and reliable test data, solving wear and heating problems, and overcoming vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

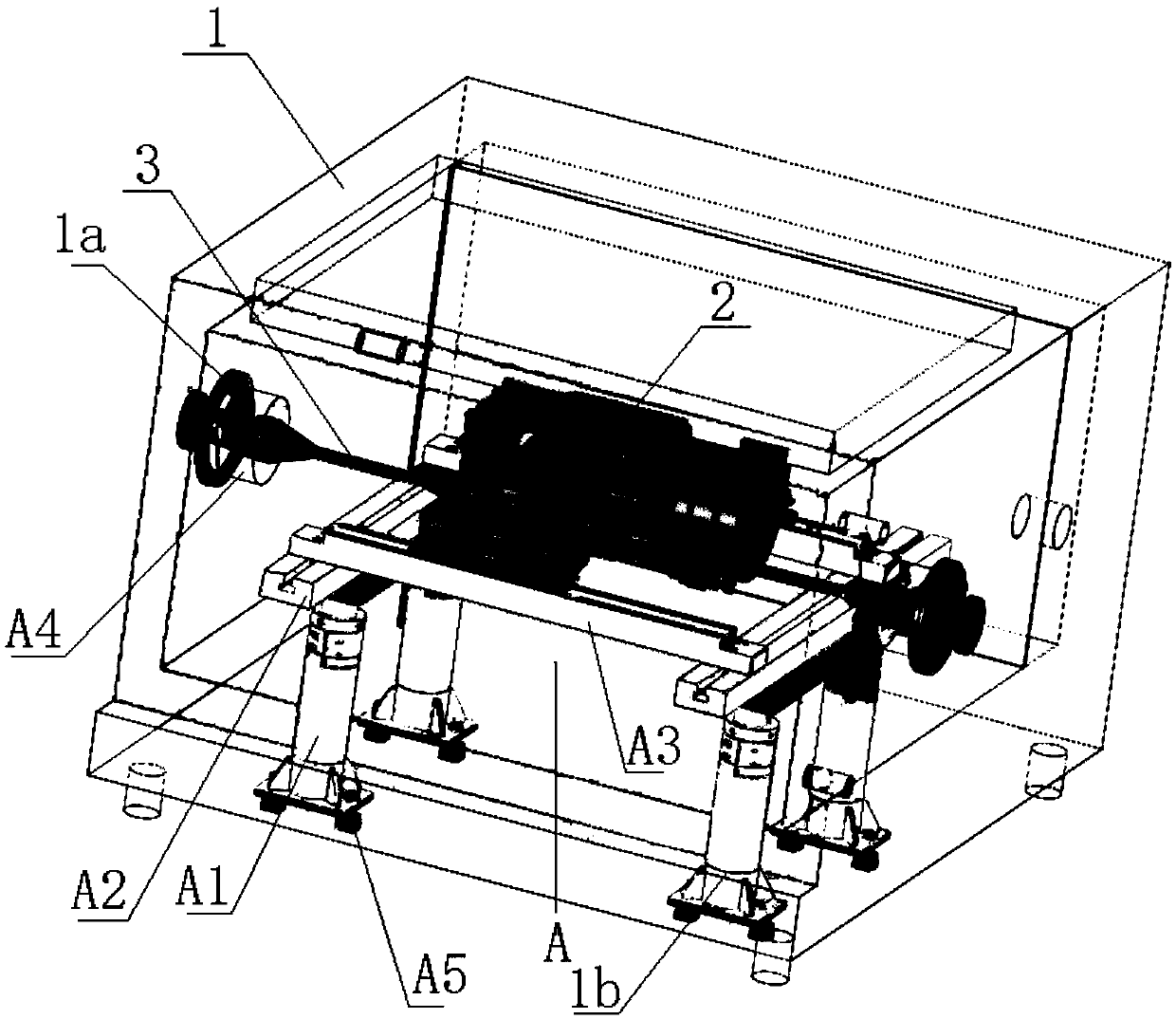

[0024] Such as figure 1 As shown, a sealed environmental chamber for a powertrain temperature test of a pure electric vehicle includes a cuboid-shaped environmental chamber body 1 and a power assembly 2. The environmental chamber body is a closed structure as a whole, and in The two sides of the environmental cabin body are provided with connecting holes 1a for the half shaft of the powertrain;

[0025] The environmental chamber cabin body 1 is provided with a powertrain bracket A in the middle position inside it, and the powertrain bracket is fixed at the middle position inside the environmental cabin cabin body through the bracket positioning hole 1b provided on the bottom surface inside the environmental chamber cabin body, Among them, there are 4 bracket positioning holes, which form a rectangular area;

[0026] The power assembly 2 is placed on the power assembly bracket A and fixed, and the two power assembly semi-shafts 3 of the power assembly respectively protrude fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com