Method for protecting frequency converter under high-current condition of separator

A frequency converter, high-current technology, applied in electrical components, AC motor control, output power conversion devices, etc., can solve the problems of large rotational inertia, increased cost, heavy drum weight, etc., to overcome impact, smooth start and stop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

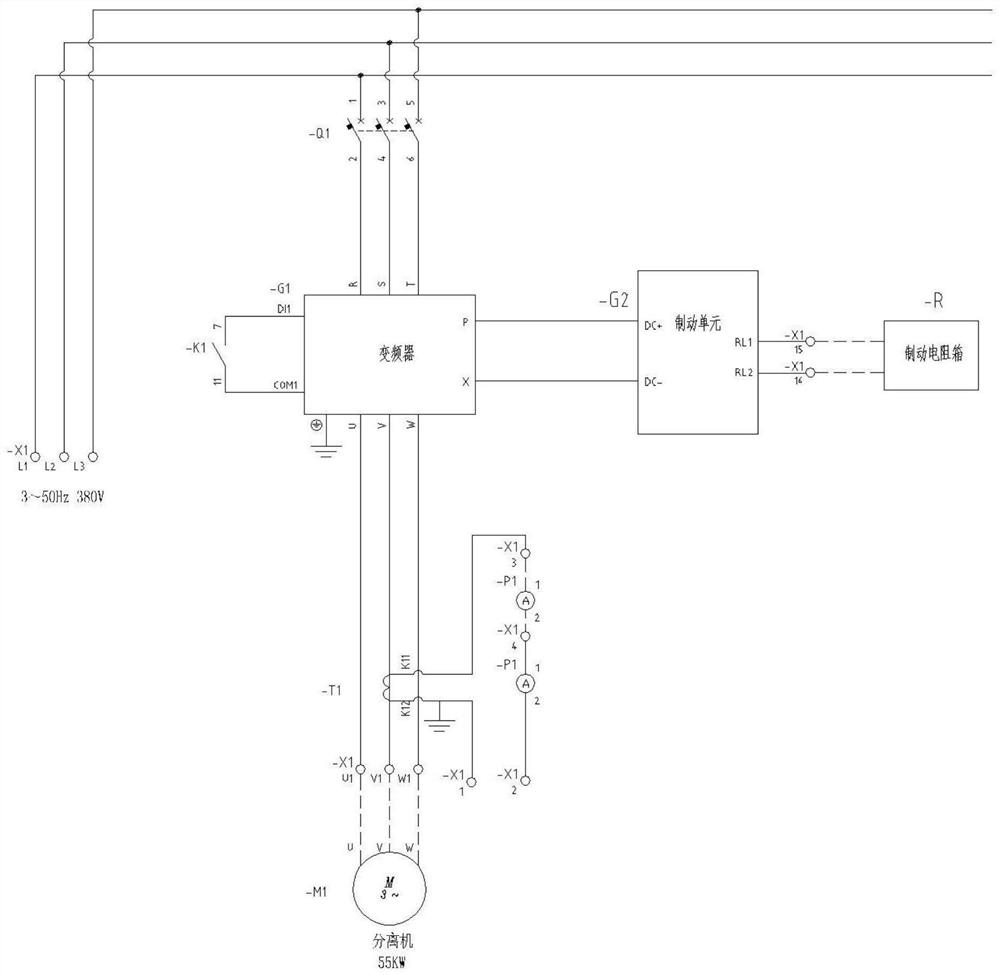

[0011] see figure 1 , this embodiment provides a protection method for the frequency converter in the case of a high current of the separator, and the impact of the high current on the frequency converter is overcome by adding a braking resistor to the frequency converter and PLC control, which has the advantages of cost reduction, efficiency increase, and high safety The advantages.

[0012] The invention provides a protection method for the frequency converter under the condition of high current of the separator. At least one air switch is connected in series between the frequency converter and the incoming line of the three-phase alternating current, and the start command of the frequency converter is canceled before the slag discharge solenoid valve is opened ;When the slag discharge solenoid valve is opened, the inverter tends to stop and decelerate, and at the same time, the PLC detects the running current of the motor. After the slag discharge solenoid valve is closed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com