Silage feed fine strip kneading machine

A silage and silk machine technology, applied in the field of agricultural machinery, can solve the problems of inconvenient transportation, manual injury, poor safety, etc., and achieve the effects of easy disassembly and installation, saving transportation space, and facilitating digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

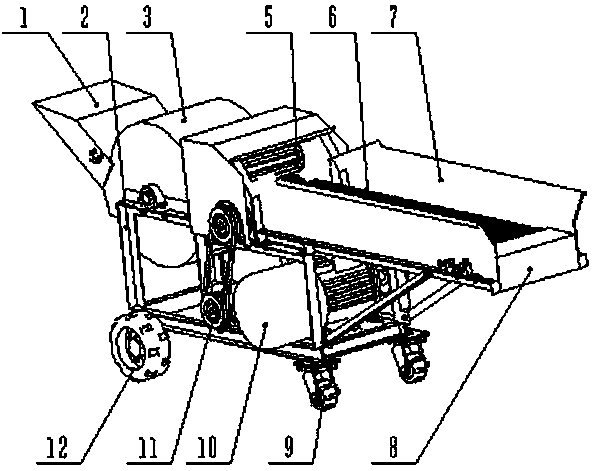

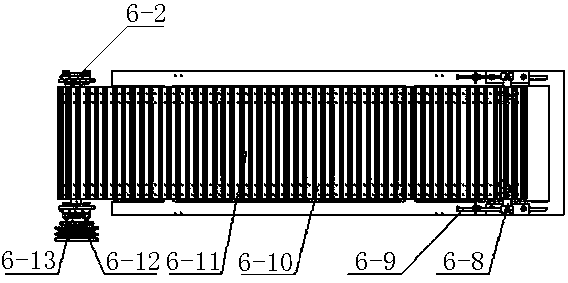

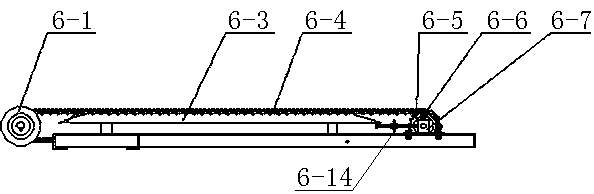

[0028] Such as figure 1 , Figure 6 , Figure 7 and Figure 8 Shown, a kind of silage kneading silk machine comprises frame 2, and the bottom of frame 2 is provided with two large traveling wheels 12 and two universal traveling wheels 9, convenient to move and turn to conveniently, and frame 2 is provided with Conveying device 6, feeding device 5, pulverizing device 3 and power unit, the outlet of conveying device 6 is connected with the inlet of feeding device 5, the outlet of feeding device 5 is connected with the entrance of pulverizing device 3, the outlet of pulverizing device 3 A baffle plate 1 is provided, and the baffle plate 1 is hinged to the outlet of the crushing device 3. The crushing device 3 includes a crushing support frame 3-15 fixed on the frame 2, and two spindle installation sleeves pass through the crushing support frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com