Pedal type dough kneading machine

A kneading machine and foot-operated technology, applied in dough mixers, structural components of mixing/kneading machinery, baking, etc., can solve the problems of hand-influenced kneading effect, manual addition of flour, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

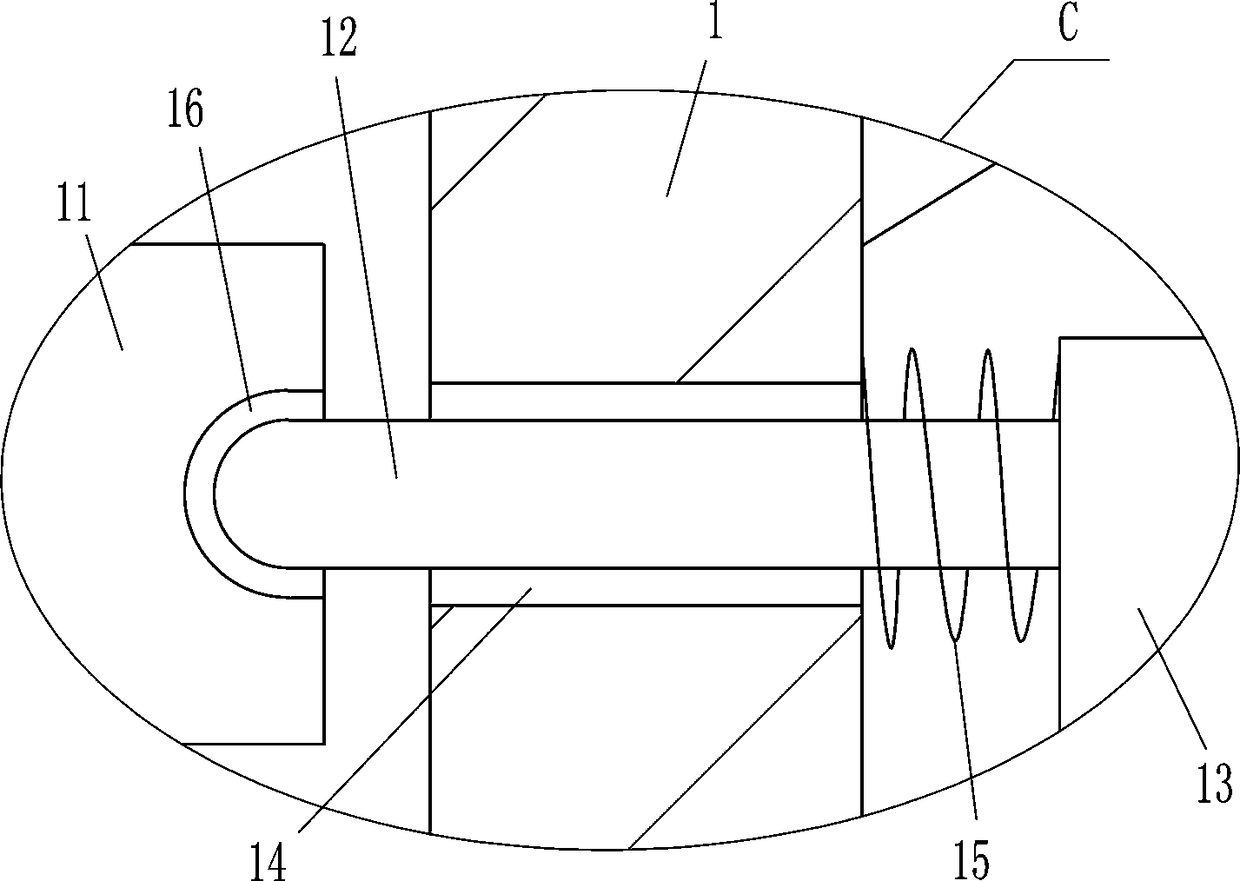

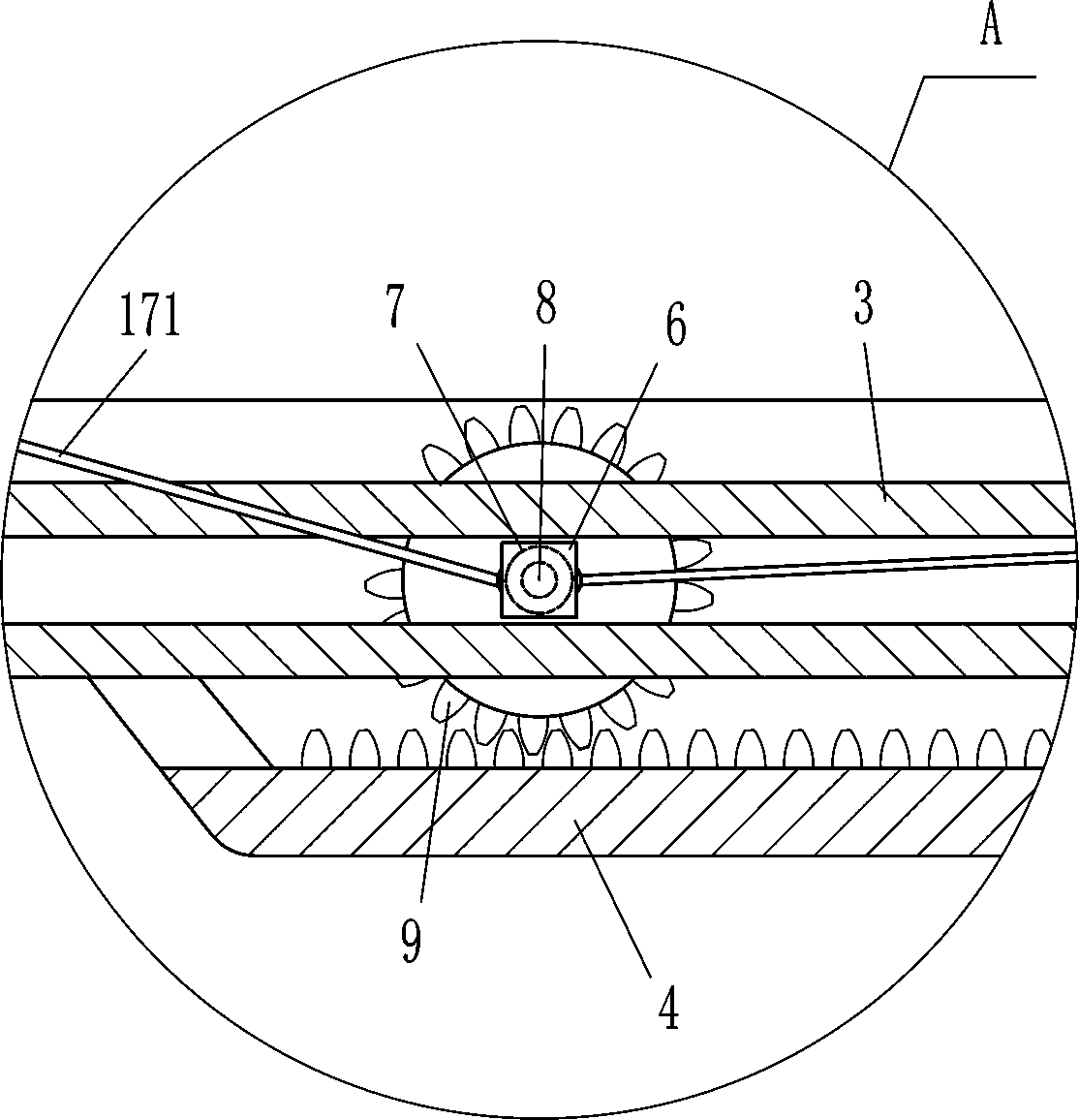

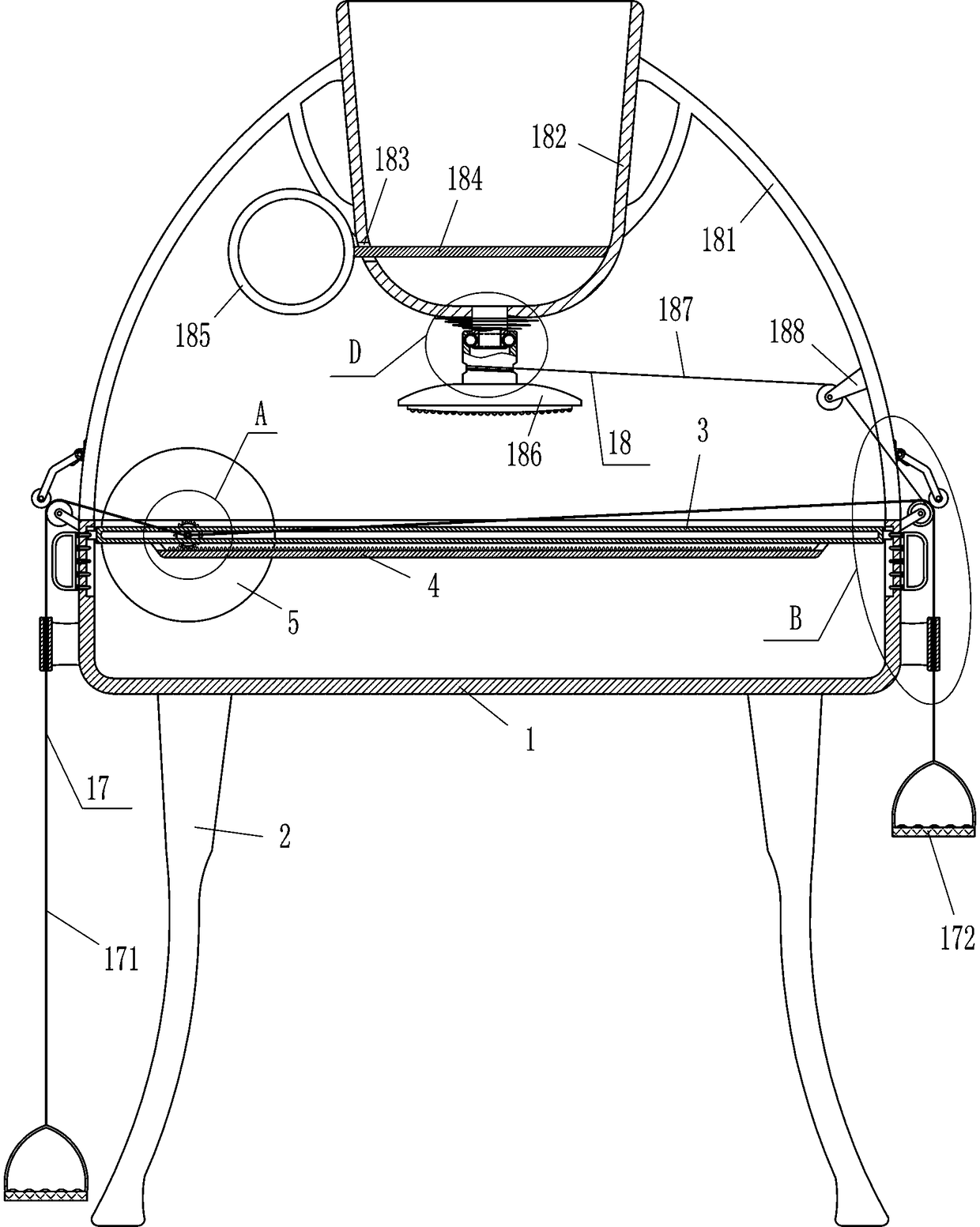

[0018] A foot-operated dough mixer, such as Figure 1-4 As shown, it includes a frame body 1, legs 2, a straight orifice plate 3, a rack 4, a roller 5, a horizontal slider 6, a bearing seat 7, a rotating shaft 8, a gear 9, a vertical slider 11, and a lever 12 , the handle 13, the first spring 15 and the driving mechanism 17, the outer bottom of the frame body 1 is symmetrically connected with the legs 2 on the left and right sides, the frame body 1 is connected with the legs 2 through bolt connection, and the left and right sides of the frame body 1 There are vertical chute 10 that plays a guiding role on both sides of the top, front and rear sides of the two sides. The sliding type in the vertical chute 10 is provided with a vertical slider 11, and the vertical slider 11 is slidably matched with the vertical chute 10. , there are two in-line orifice plates 3 that play a guiding role, and the in-line orifice plates 3 are respectively installed between the inner sides of the ve...

Embodiment 2

[0020] A foot-operated dough mixer, such as Figure 1-4 As shown, it includes a frame body 1, legs 2, a straight orifice plate 3, a rack 4, a roller 5, a horizontal slider 6, a bearing seat 7, a rotating shaft 8, a gear 9, a vertical slider 11, and a lever 12 , the handle 13, the first spring 15 and the drive mechanism 17, the left and right sides of the outer bottom of the frame body 1 are fixedly connected with supporting legs 2 symmetrically, and the left and right sides of the frame body 1 are provided with vertical guides on the upper front and rear sides. Straight chute 10, sliding type in the vertical chute 10 is provided with a vertical slide block 11, and the vertical slide block 11 is slidably matched with the vertical chute 10, and there are two in-line orifice plates 3 that play a guiding role, Slotted orifice 3 is respectively installed between the inner sides of the vertical sliders 11 on the left and right sides of the front and between the vertical sliders 11 o...

Embodiment 3

[0023] A foot-operated dough mixer, such as Figure 1-5As shown, it includes a frame body 1, legs 2, a straight orifice plate 3, a rack 4, a roller 5, a horizontal slider 6, a bearing seat 7, a rotating shaft 8, a gear 9, a vertical slider 11, and a lever 12 , the handle 13, the first spring 15 and the drive mechanism 17, the left and right sides of the outer bottom of the frame body 1 are fixedly connected with supporting legs 2 symmetrically, and the left and right sides of the frame body 1 are provided with vertical guides on the upper front and rear sides. Straight chute 10, sliding type in the vertical chute 10 is provided with a vertical slide block 11, and the vertical slide block 11 is slidably matched with the vertical chute 10, and there are two in-line orifice plates 3 that play a guiding role, Slotted orifice 3 is respectively installed between the inner sides of the vertical sliders 11 on the left and right sides of the front and between the vertical sliders 11 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com