Production method of membrane electrode diffusion layer for fuel cell

A fuel cell membrane and diffusion layer technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of uneven thickness of the diffusion layer, low production safety, irritation, etc., and achieve no irritating smell and kneading effect Good, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

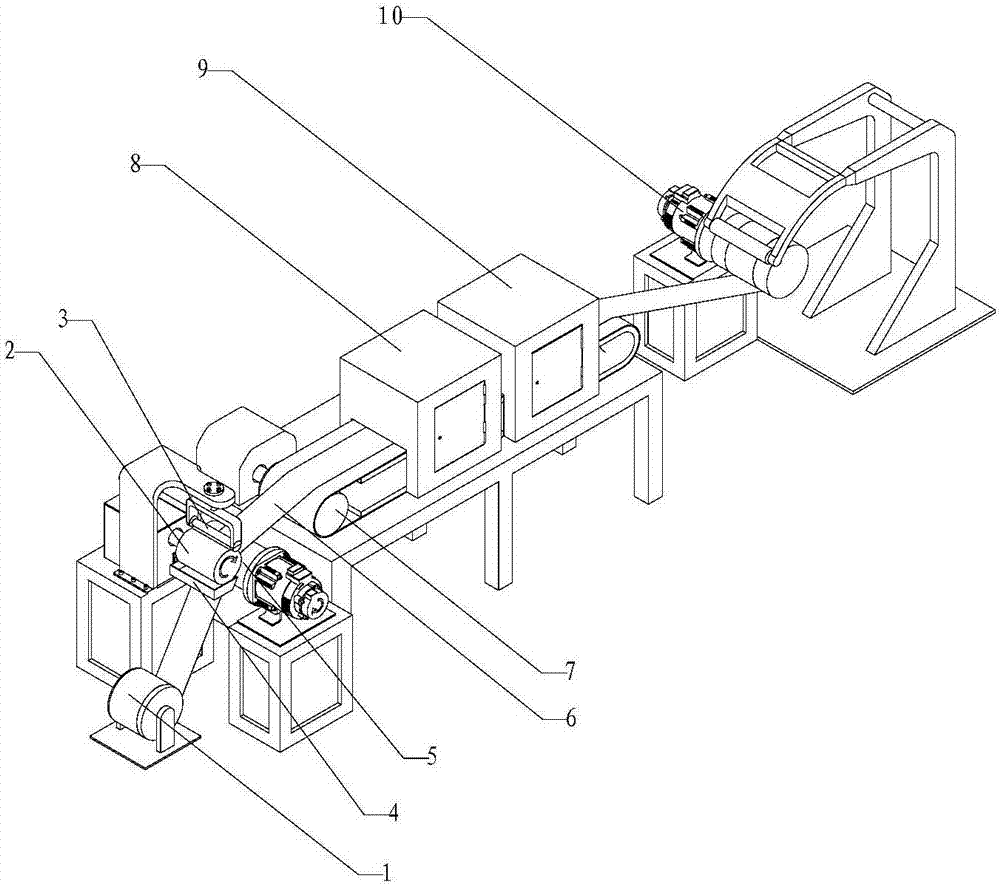

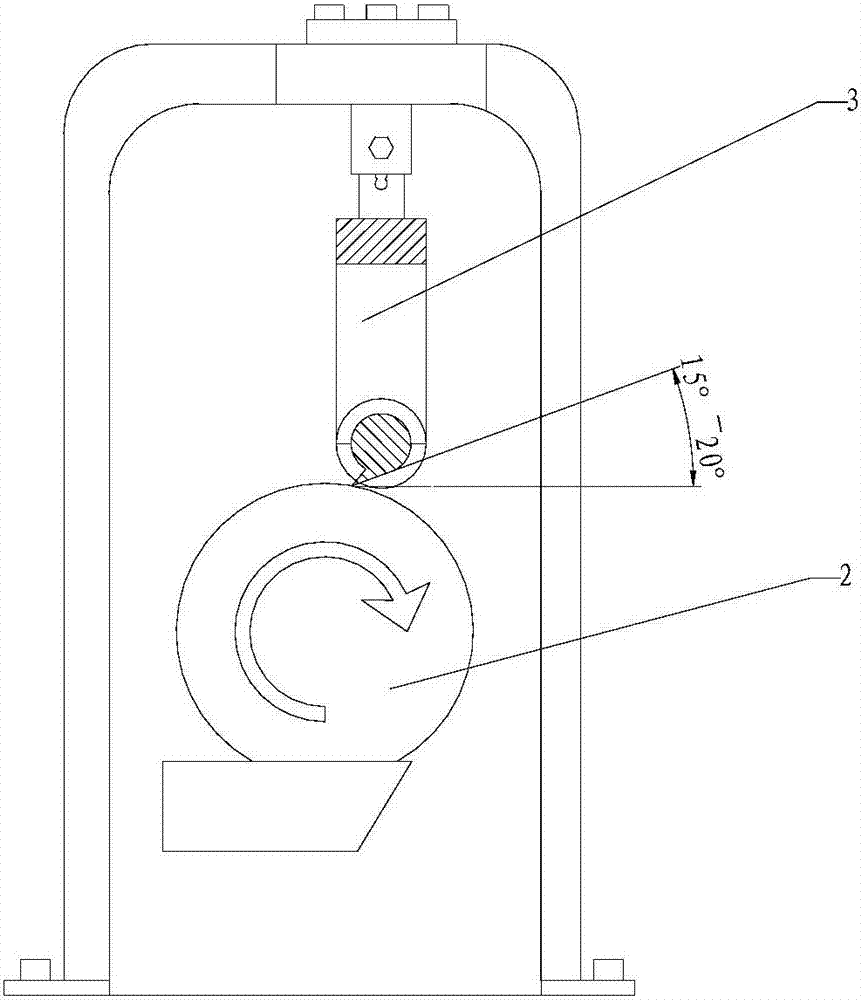

[0022] Please refer to figure 1 and figure 2 , a method for preparing a fuel cell membrane electrode diffusion layer, comprising the steps of:

[0023] Step 1. Clean the carbon paper with ethanol, dry it, dip it in polytetrafluoroethylene emulsion, and then dry it for sintering. The sintering temperature is 300-350°C and the sintering time is 20-50min. Carbon paper of tetrafluoroethylene 6;

[0024] Step 2, acetylene black, water and binding agent are formulated into carbon powder slurry, the mass ratio of acetylene black, water and binding agent is 1-3:60-62:4-6, is placed in stirring tank with 40rpm Rotate at a speed of 100rpm / min for 20-30min and then stop, check the kneading status of acetylene black and binder, adjust the amount of water, and then rotate at a speed of 100rpm / min for 2-3h, measure the viscosity to 1000-3000mPa·s, and obtain carbon Powder slurry;

[0025] Step 3, coating the carbon powder slurry in the above step 2 on the carbon paper obtained in step ...

Embodiment 1

[0038] A method for preparing a fuel cell membrane electrode diffusion layer, comprising the steps of:

[0039] Step 1. Select carbon paper 6 with a carbon content of 98% and a thickness of 12um. Clean the carbon paper 6 with ethanol and then dry it. Put it into polytetrafluoroethylene emulsion for dipping, then dry it for sintering. The sintering temperature is 300°C, the sintering time is 20min, and the carbon paper 6 loaded with polytetrafluoroethylene is prepared;

[0040] Step 2. Prepare carbon powder slurry with acetylene black, water and polytetrafluoroethylene. The mass ratio of acetylene black, water and polytetrafluoroethylene is 1:60:4. Put it in a stirring tank and rotate at 40rpm / min Stop rotating after 30 minutes, check the kneading status of acetylene black and polytetrafluoroethylene, and then rotate at 100rpm / min for 2-3 hours, measure the viscosity to 2500mPa·s, and prepare carbon powder slurry;

[0041]Step 3, the carbon powder slurry of the above-mentioned...

Embodiment 2

[0045] A method for preparing a fuel cell membrane electrode diffusion layer, comprising the steps of:

[0046] Step 1. Clean the carbon paper 6 with ethanol, dry it, put it into the polytetrafluoroethylene emulsion, impregnate it, and then dry it for sintering. The sintering temperature is 300°C, and the sintering time is 20 minutes. carbon paper 6;

[0047] Step 2. Prepare carbon powder slurry with acetylene black, water and polytetrafluoroethylene. The mass ratio of acetylene black, water and polytetrafluoroethylene is 1:60:4. Put it in a stirring tank and rotate at 40rpm / min Stop rotating after 20 minutes, check the kneading status of acetylene black and polytetrafluoroethylene, and then rotate at 100rpm / min for 2 hours, measure the viscosity to 1000mPa·s, and prepare carbon powder slurry;

[0048] Step 3, put the carbon powder slurry in the above step 2 in the trough 4, and the carbon paper 6 obtained in the step 1 is drawn to the gap between the coating roller 2 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com