Silage rubbing filament machine

A silage and silk machine technology, applied in agricultural machinery and tools, cutting equipment, grain processing, etc., can solve the problems of poor kneading effect, inability to crush, and palatability of straw processing, so as to improve the kneading effect and avoid accumulation stuck effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

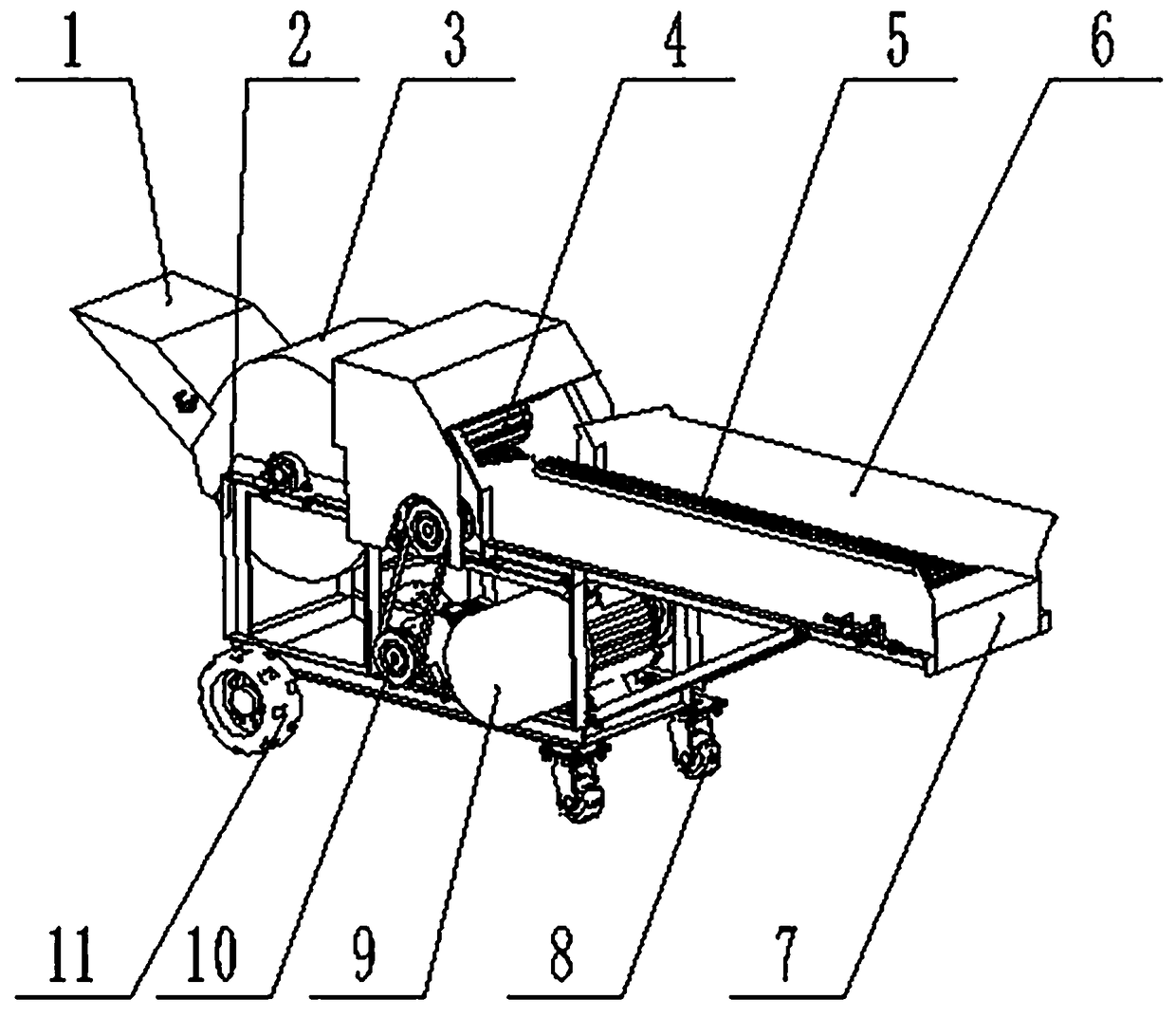

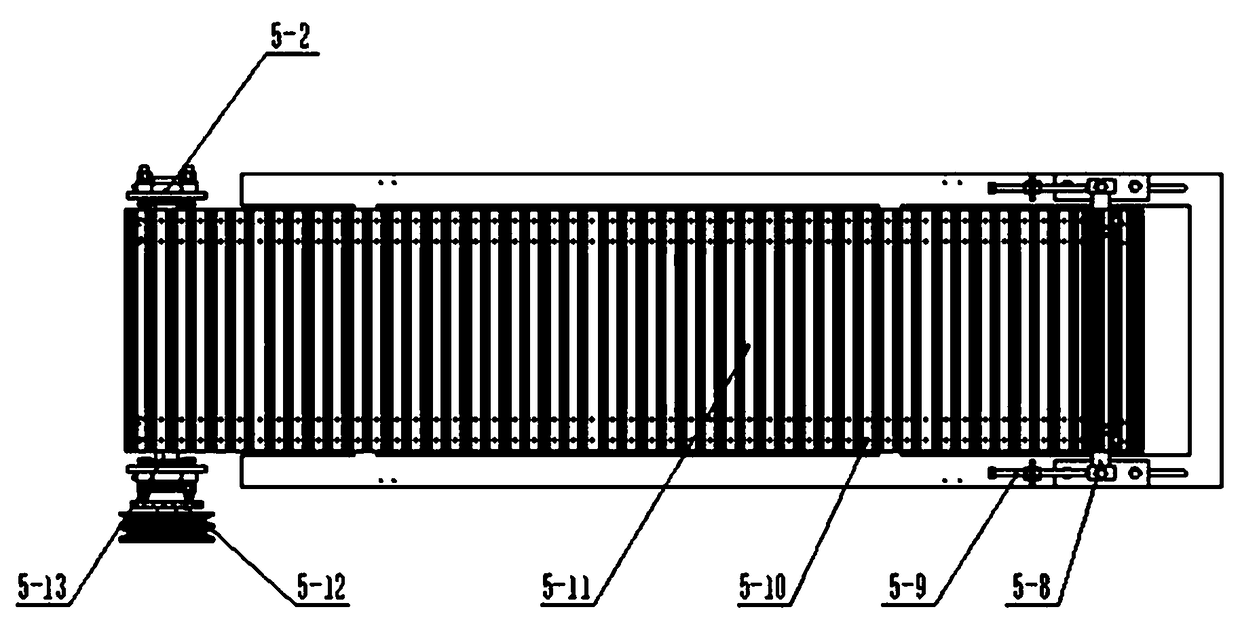

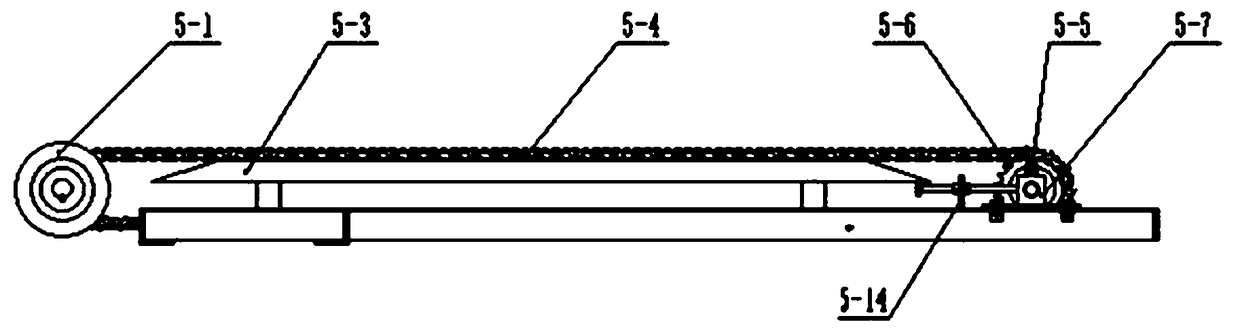

[0029] Such as figure 1 , Figure 4 , Figure 5 , Figure 6As shown, a kind of silage kneading silk machine comprises frame 2, and the bottom of frame 2 is provided with two large traveling wheels 11 and two universal traveling wheels 8, convenient to move and turn to conveniently, and frame 2 is provided with Conveying device 5, feeding cutting device 4, pulverizing device 3 and power unit, power device comprises electric motor 9 and reduction motor 10, the outlet of conveying device 5 is connected with the inlet of feeding cutting device 4, the outlet of feeding cutting device 4 is connected with The inlet of the pulverizing device 3 is connected, the outlet of the pulverizing device 3 is provided with a baffle plate 1 and the material baffle plate 1 is hinged with the outlet of the pulverizing device 3, and the feeding and cutting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com