Tea rolling machine

A kneading machine and tea technology, which is applied in the field of tea equipment, can solve the problems that tea cannot be fully kneaded, has poor fluidity, and affects the quality of tea, and achieves the effects of easy kneading, improved kneading efficiency, and enhanced fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

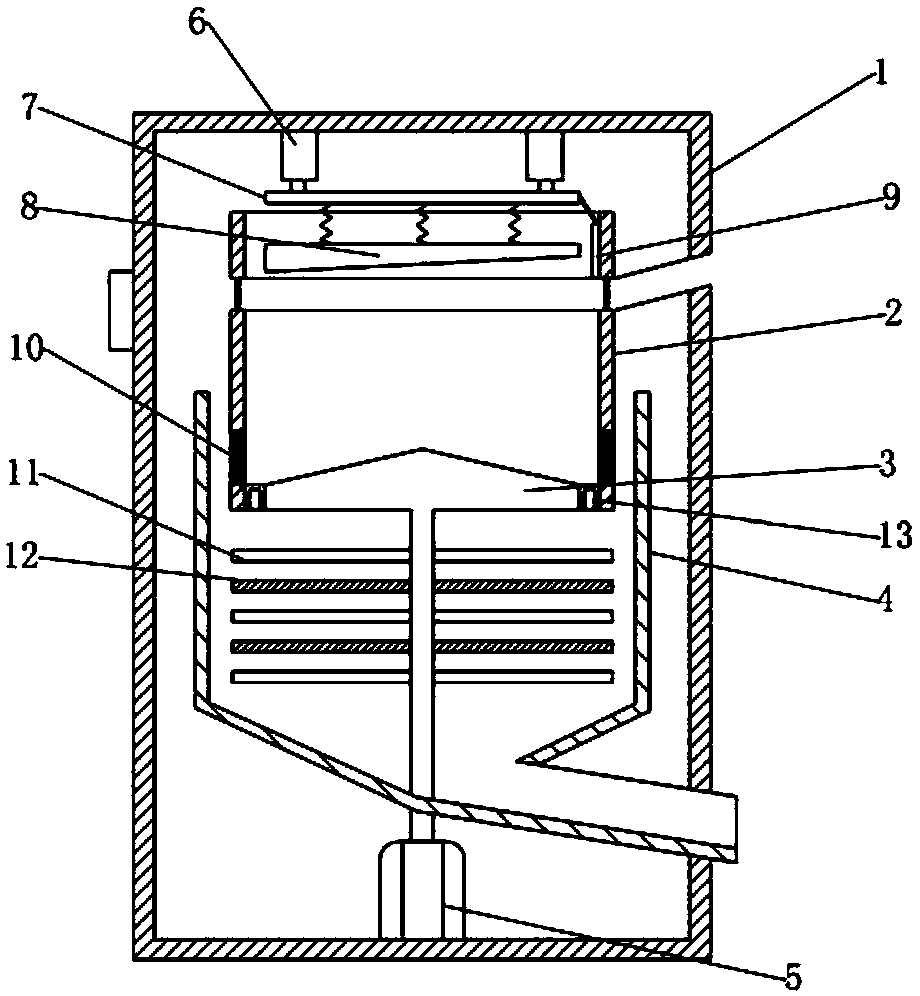

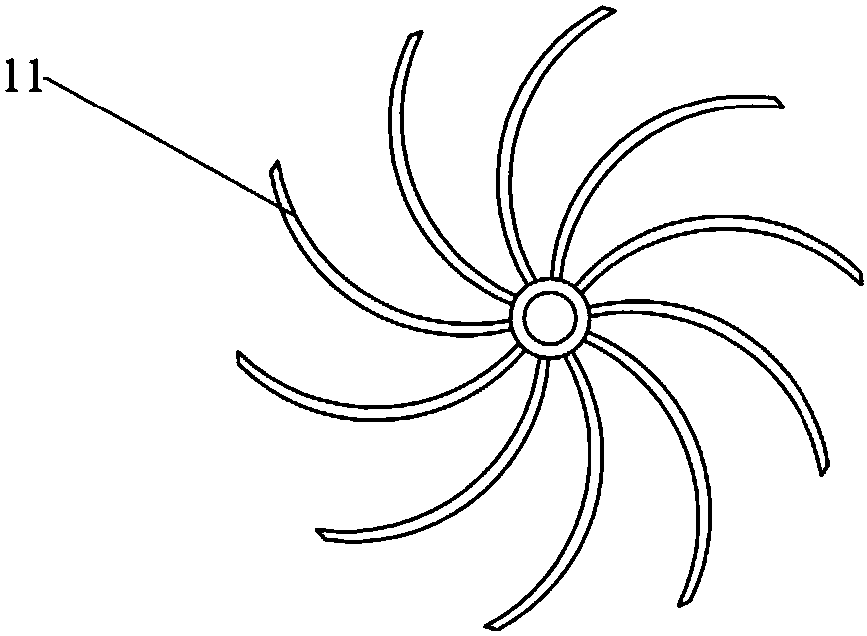

[0026] Such as figure 1 with figure 2 As shown, a tea rolling machine includes a housing 1, a first rolling barrel 2, a rolling plate 3, a second rolling barrel 4 and a motor 5. The top in the housing 1 is equipped with a cylinder 6, the bottom of the cylinder 6 is provided with a pressure plate 7, there are six springs below the pressure plate 7, the springs are distributed in a circular array on the pressure plate 7, and a pressure plate 8 is connected below the spring; There is also a feed port on the side wall of the housing 1; the first kneading barrel 2 is fixed in the middle of the housing 1 by a bracket, the pressure plate 8 and the pressing plate 7 can extend into the first kneading barrel 2, and the first kneading barrel Move in 2; On the sidewall of the first kneading barrel 2, there is a feed inlet corresponding to the feed inlet, the feed inlet and the feed inlet are communicated through pipelines, the bottom of the first kneading barrel 2 is a screen 10, the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com