Automatic material replacing and connecting device and prepressing gas circuit

A feeding device and automatic technology, applied in the direction of cardboard articles, etc., can solve the problems of complex operation process, unsatisfactory cylinder pressure, increase production cost, etc., and achieve the effect of reducing manufacturing cost, reducing production cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

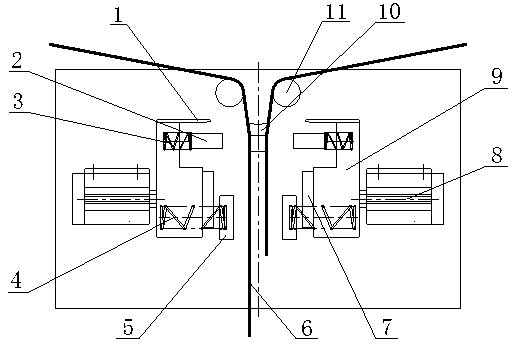

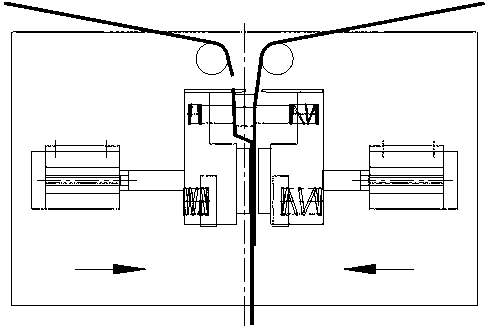

[0010] Embodiment 1: with reference to attached Figure 1-5 . The automatic material changing device and the pre-compressed air circuit include a cylinder 8, the piston rod of the cylinder 8 is connected with a slider 9, and the two sliders 9 are symmetrical to each other, and the slider 9 is equipped with a cutting mechanism and a material receiving mechanism. Above the material receiving mechanism, two material sticks 11 are arranged above the slide block 9 . The cutting mechanism is composed of a cutter 1, a buffer device and a bottom knife 10. The cutter 1 is installed above the slider 9 and is left-right symmetrical. The buffer device is composed of a small buffer plate 2 and a buffer spring 3. On the block 9, the other end connects the small buffer sheet 2, and the working surface of the small buffer sheet 2 matches with the working surface of the bottom knife 10, and the bottom knife 10 is fixedly installed on the overall production equipment. The material receiving m...

Embodiment 2

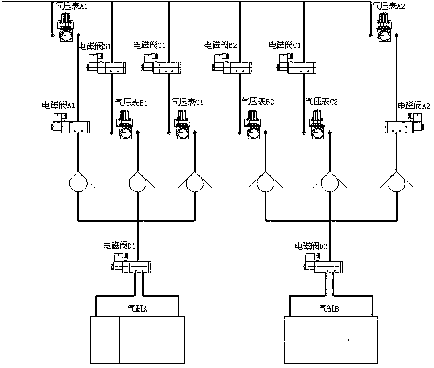

[0011] Embodiment 2: On the basis of Embodiment 1, when the left side extends into the stock, the solenoid valve B 1 and D 1 Pilot air path, barometer B 1 Boost the pressure to 1.5 bar, so that the cylinder A punches 1.5 bar. At this time, the small buffer plate 2 on the left presses the stock, but the left cutter 1 is not in contact with the bottom knife 10; the solenoid valve A 2 and D 2 The air circuit is connected, and the cylinder B presses 6 bar. At this time, the small buffer sheet 2 on the right presses the material, and the cutter 1 cuts the material. At this time, the left and right large buffer sheets 7 also have a certain pressing force on each other; the solenoid valve C 1 Action, Barometer C 1 Boost the pressure to 4 bar, so that the cylinder A is pressurized to 4 bar. At this time, the pressing force between the left and right large buffer plates 7 increases, thereby crimping the two materials; finally, the solenoid valve D 1 and D 2 action, cylinder A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com