Packaging bag all-round shaping conveyor

A kind of packaging bag, all-round technology, applied in packaging and other directions, can solve the problems affecting stacking, clean working environment, deviation of packaging bags, etc., to achieve the effect of simple structure, lower price, and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

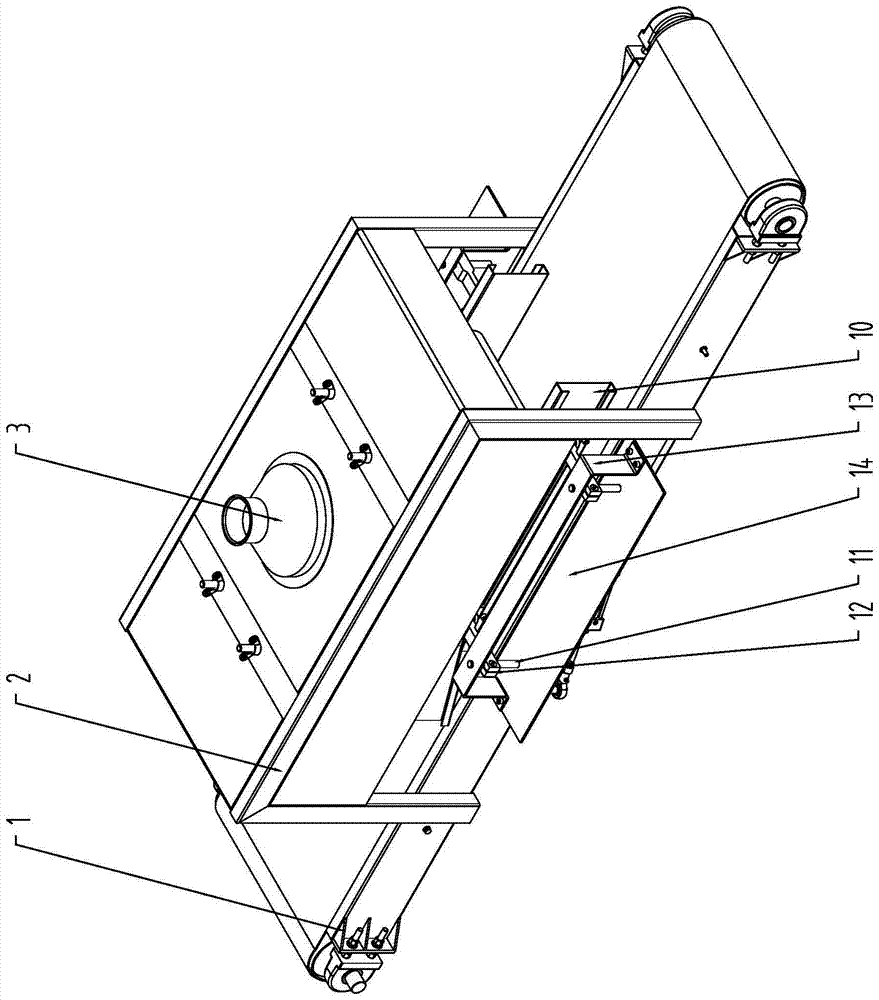

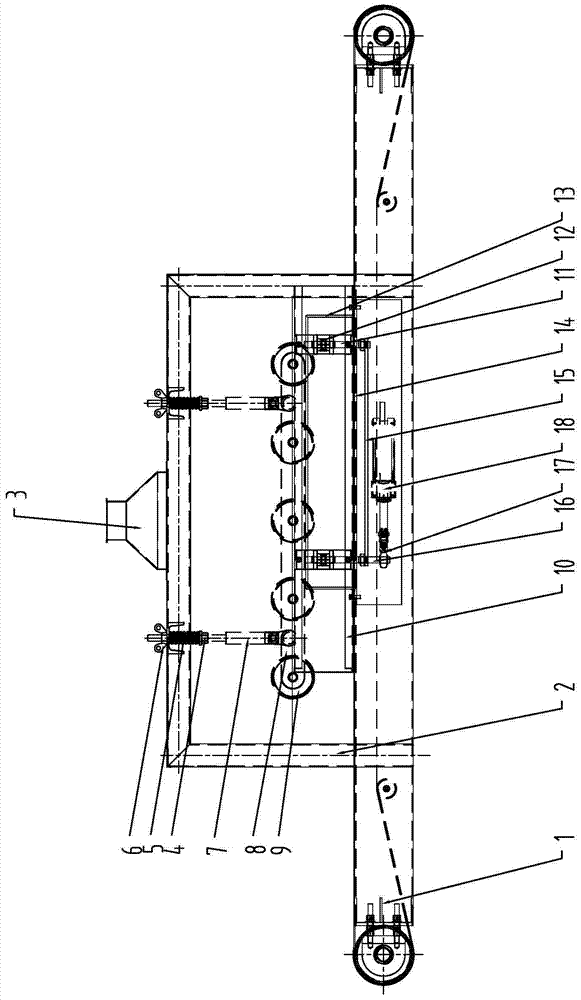

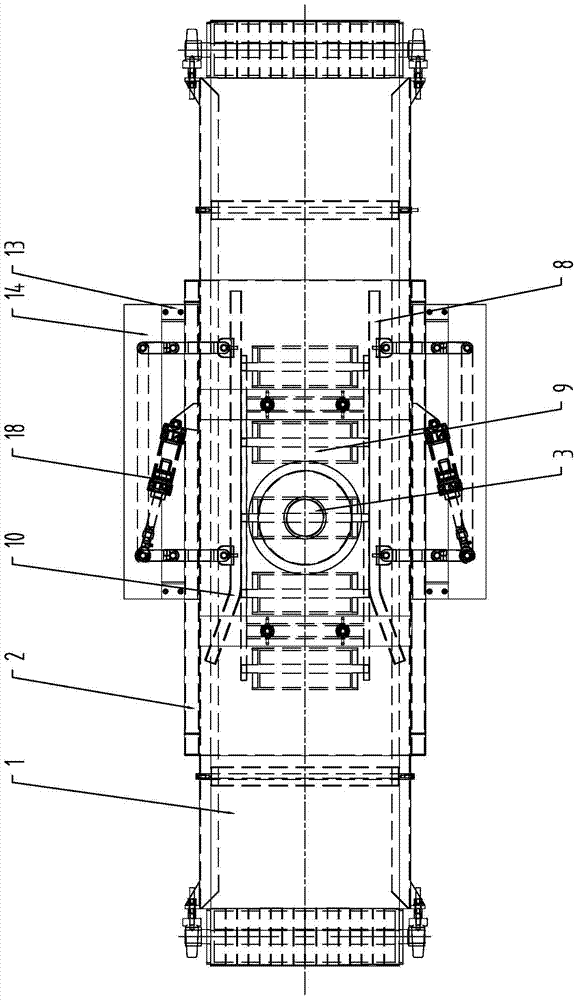

[0017] Such as Figure 1~4 Shown, the present invention mainly comprises belt conveyor 1, pressure roller mechanism, shaping mechanism and dedusting mechanism, and belt conveyor 1 is used for conveying packing bag, and the frame both sides of belt conveyor 1 is fixed support frame 2, and the inside of support frame 2 A pressing roller mechanism is provided, and the pressing roller mechanism can squeeze the upper surface of the packaging bag.

[0018] The pressure roller mechanism includes a plurality of pressure rollers 9 , which are jointly rotatably connected to the pressure roller bracket 8 , and the upper end of the pressure roller bracket 8 is connected to the support frame 2 through a plurality of suspension rods 7 . The upper end of each suspender 7 is fitted with a spring 5 , the lower end of the spring 5 is positioned by the lower adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com