Outer-layer porous orthopedic hard implant material with integrated radial structure and function and preparation method and application thereof

An implant material and function technology, applied in prosthesis, medical science, tissue regeneration, etc., can solve the problems of increasing the difficulty of processing and implantation, increasing the cost of material preparation, and changing mechanical properties, so as to maintain the pore structure characteristics and biological activity. Ability, the preparation process is convenient and clean, and the effect of short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for preparing a radial structure-function integrated outer layer porous orthopedic hard implant material, which specifically includes the following steps:

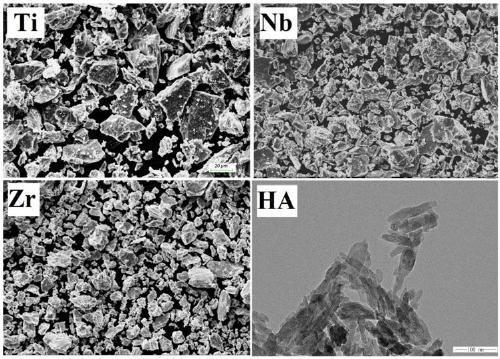

[0036] (1) By Ti: 74%, Nb: 20%, Zr: 6% by mass percentage, in the vacuum glove box, take by weighing Ti, Nb, Zr metal powder (titanium, The scanning electron micrographs of niobium and zirconium metal powders and the transmission electron micrographs of HA are as follows figure 1 shown); the weighed Ti, Nb, Zr metal powders are put into the cemented carbide steel ball milling jar, the ball milling dispersant absolute ethanol is added, and stainless steel ball milling balls are added according to the ball-to-material ratio 4:1 (mass ratio), wherein the stainless steel The size ratio of ball milling balls is 2:1 (mass ratio). After the assembly is completed and the tank is sealed, this step is completed in a vacuum glove box;

[0037] (2) Put the sealed tank body of step (1) into a ...

Embodiment 2

[0046] This embodiment provides a method for preparing an outer porous orthopedic hard implant material with consistent radial composition and structural changes, which specifically includes the following steps:

[0047] (1) By Ti: 70%, Nb: 17%, Zr: 13% by mass, in a vacuum glove box, take respectively Ti, Nb, Zr metal powders with a purity of 99.9% and an average particle size of 50 μm; weigh The Ti, Nb, Zr metal powders are put into the hard alloy steel ball mill tank, add ball mill dispersant dehydrated alcohol, add stainless steel ball mill balls by ball-to-material ratio 4:1 (mass ratio), wherein the size ball ratio of stainless steel ball mill balls It is 2:1 (mass ratio). After the assembly is completed and the tank is sealed, this step is completed in a vacuum glove box;

[0048] (2) Put the sealed tank body of step (1) into a ball mill for ball milling and mixing. The mechanical ball milling parameters are: rotating speed: 300r / min, ball milling time: 10 hours. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com