Low-sensitization and high-elasticity mashed shrimp and preparation method thereof

A production method, shrimp slippery technology, applied in food science and other fields, can solve problems such as allergic reactions of allergic patients, and achieve the effects of avoiding food quality degradation, good stability, and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for making shrimp slippery, comprising the following steps:

[0027] Put the 0.8% (w / w) trehalose solution into a dielectric barrier plasma processing equipment (Shenzhen Youpulai Plasma Technology Co., Ltd., CP-5602; the same below) for 10 minutes (voltage 50kV, current 1mA), and prepare The antisensitizing solution was placed in the refrigerator to cool down to 4°C. Wash the shrimp, remove the head, remove the shell, remove the shrimp line, and get the shrimp, mix the shrimp with the desensitization liquid according to the mass volume ratio of 2:1, put it into the meat grinder and stir 3 times (30s each time, stop for 3min ) to prepare shrimp homogenate. The prepared shrimp homogenate was subjected to ultrasonic treatment (300w, 30kHz, 30s), and a sizing solution containing 30% (w / w) starch and 0.3% (w / w) ascorbic acid was added according to the mass ratio of 3:1, and put into Stir in the meat grinder for 3 times (30 seconds each time, stop for 1 minute) to...

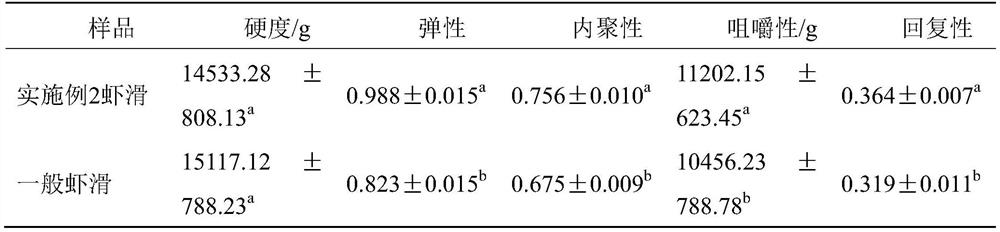

Embodiment 2

[0029] A method for making shrimp slippery, comprising the following steps:

[0030] Put the 1.2% (w / w) trehalose solution in a dielectric barrier plasma processing equipment for 20 minutes (voltage 50kV, current 1mA), and put the prepared desensitizing solution in a refrigerator to cool down to 4°C. Wash the shrimp, remove the head, remove the shell, remove the shrimp line, and get the shrimp, mix the shrimp with the desensitization liquid according to the mass volume ratio of 2:1, put it into the meat grinder and stir 3 times (30s each time, stop for 3min ) to prepare shrimp homogenate. The prepared shrimp homogenate was subjected to ultrasonic treatment (500w, 40kHz, 60s), and a sizing solution containing 40% (w / w) starch and 0.5% (w / w) ascorbic acid was added according to the mass ratio of 3:1. Stir in the meat grinder for 3 times (30 seconds each time, stop for 1 minute) to obtain shrimp paste, and knead the shrimp paste into a shape, which is hypoallergenic and highly e...

Embodiment 3

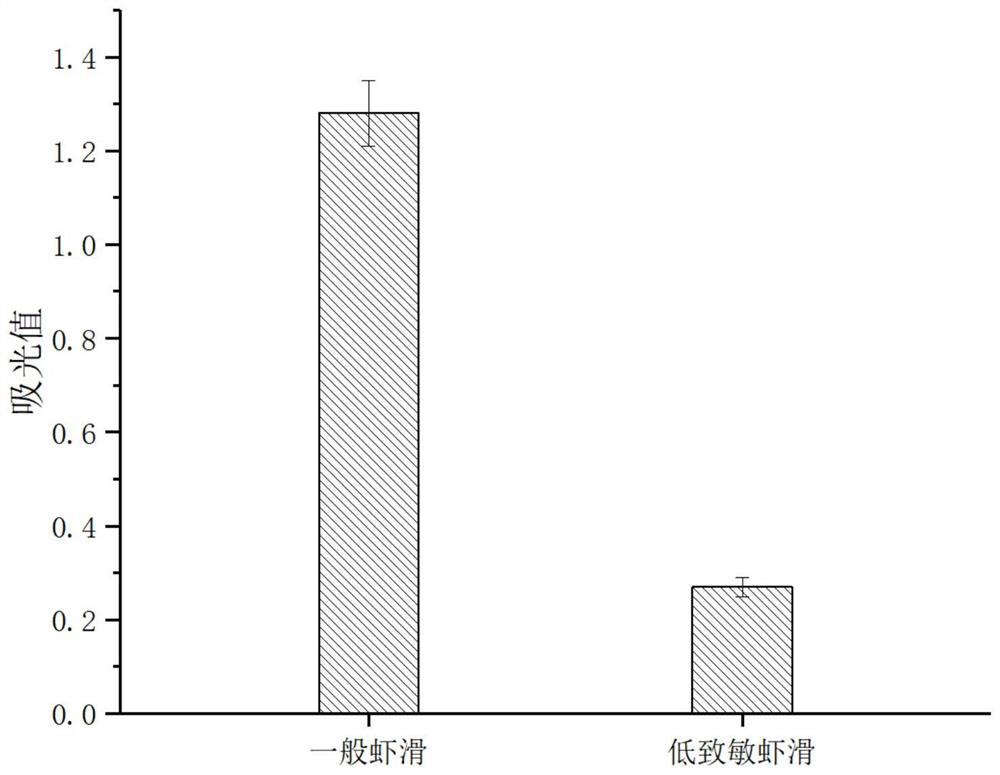

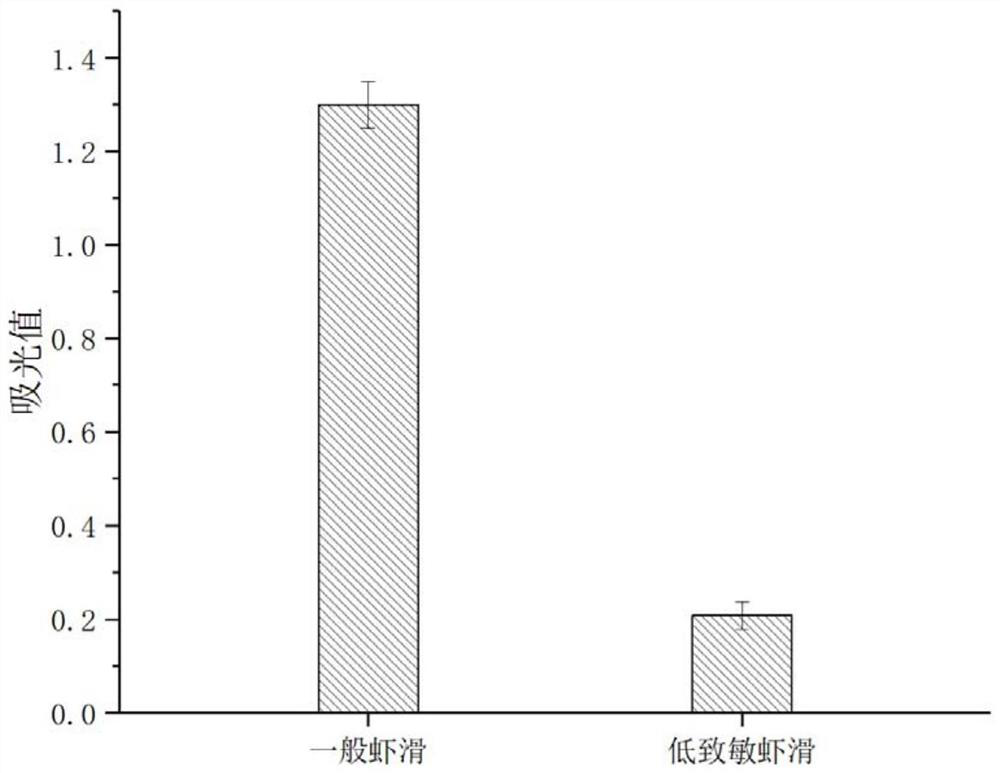

[0032] 1) By indirect ELISA, compare the difference between the general shrimp slip and the hypoallergenic shrimp slip obtained in Example 1;

[0033] The preparation method of the general shrimp slip is the same as that of Example 1, but its desensitizing solution lacks the step of dielectric barrier plasma processing;

[0034] Specific steps are as follows:

[0035] (1) Sample pretreatment: Take an appropriate amount of shrimp slip, add low-temperature PBS solution, use a tissue homogenizer to homogenize, let stand on ice for five minutes, and centrifuge for 10 minutes under a centrifugal force of 1500g, discard the precipitate, and adjust the concentration to 10μg / mL.

[0036] (2) Indirect ELISA: Fix the processed samples on a solid phase carrier, combine with the serum of patients with shrimp allergy, and then bind the serum of patients with shrimp allergy through HRP-labeled goat anti-human secondary antibody, and finally add the bottom substance, a color reaction occu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com