Method for preparation of egg white oligopeptide having high F value

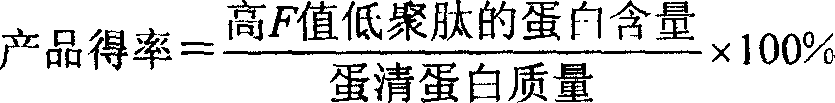

A technology of egg white and oligopeptides, applied in the direction of fermentation, etc., can solve the problems of low product yield, low F value of oligopeptides with high F value, etc., and achieve the effects of high yield, short cycle and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: The steps of the method for preparing egg white oligopeptides with high F value in this embodiment are as follows:

[0011] a. Raw material pretreatment: wash the eggs, then beat the eggs to separate the egg whites, then add water to the egg whites so that the mass percentage concentration of protein in the egg whites is 3% to 11%, and then pour the diluted egg white liquid into the reaction kettle, at 80 to 100 Heating at ℃ for 5-30 minutes to obtain denatured egg white;

[0012] b. Protein hydrolysis: the first step of hydrolysis: Stir the denatured egg white obtained in step a, lower the temperature to 40°C to 70°C, adjust the pH of the denatured egg white to 7.0 to 9.0, and then add 2% to 8% of denatured egg white Protease A with the highest protein quality, hydrolyze at a pH of 7.0 to 9.0 with constant stirring for 1 to 6 hours; after hydrolysis, adjust the pH to 4.0 to 6.0, then heat to 80 to 100°C, and react for 5 to 30 minutes Inactivate the activ...

specific Embodiment approach 2

[0017] Specific embodiment two: In this embodiment, in step a, the mass percent concentration of protein in the egg white is 5%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: In this embodiment, in step a, the mass percent concentration of protein in the egg white is 8%. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com