Industrial manufacturing method and use of allergen-eliminated partly appropriately-hydrolyzed casein peptide

A moderately hydrolyzed and casein peptide technology, applied in the biological field, can solve the problems of dangerous operation, complex process, difficult industrial production, etc., and achieve the effect of eliminating allergenic activity and easy digestion and absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

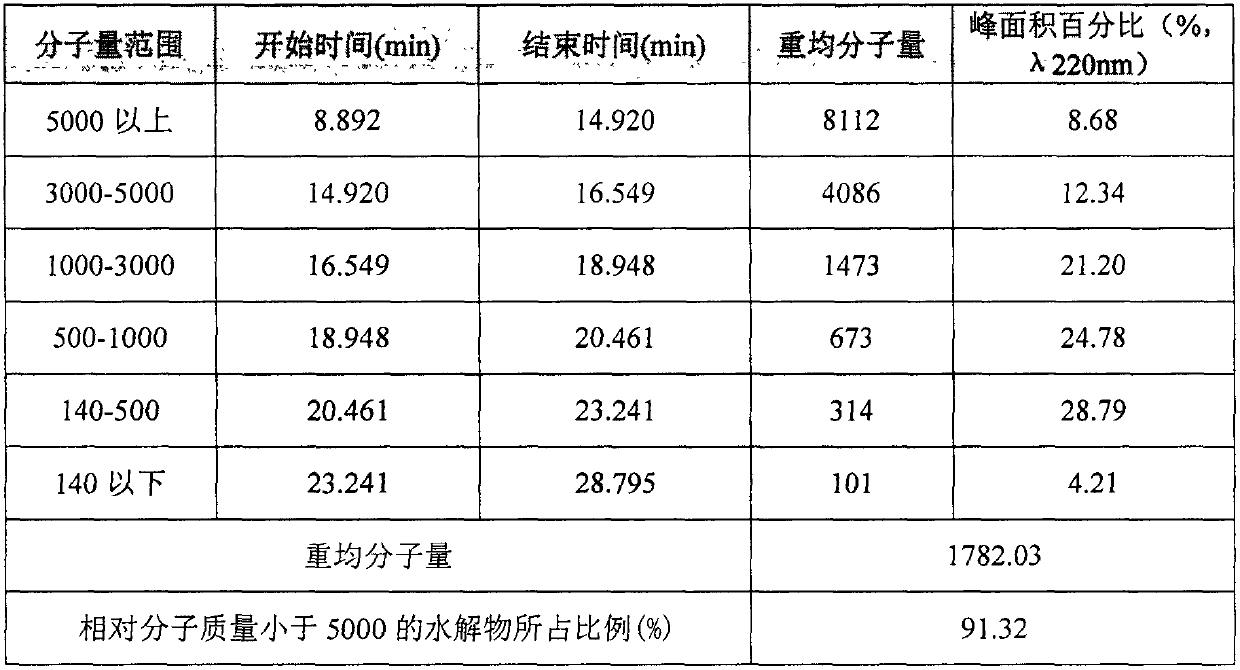

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific examples, but the scope of the present invention is not limited. Its specific process route consists of the following steps:

[0020] 1. Preparation of Moderately Hydrolyzed Casein Peptide Powder

[0021] Add 500kg of casein powder into the reaction tank, mix water and casein at a weight ratio of 10%, heat to 85°C, and keep stirring for 20 minutes. Lower the temperature to 50°C, add neutral protease and papain at 3500 units of enzyme per gram of protein, and perform enzymatic hydrolysis for 3.5 hours at a temperature of 50°C. Then, heat the enzymolysis solution to 115°C and inactivate the enzyme for 10 minutes.

[0022] Centrifuge the enzymolysis solution with a tubular centrifuge at a speed of 14000r / min, separate the supernatant and slag, and retain the centrifugation supernatant. The supernatant was filtered with a microfiltration and ultrafiltration device with a pore siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com