System for automatically producing vermicelli and glass noodles

An automatic production and vermicelli technology, which is applied in application, food preparation, food science, etc., can solve the problems of low production efficiency, high scrap rate, high failure rate, etc., and achieve the effect of improving yield rate, stable product quality and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

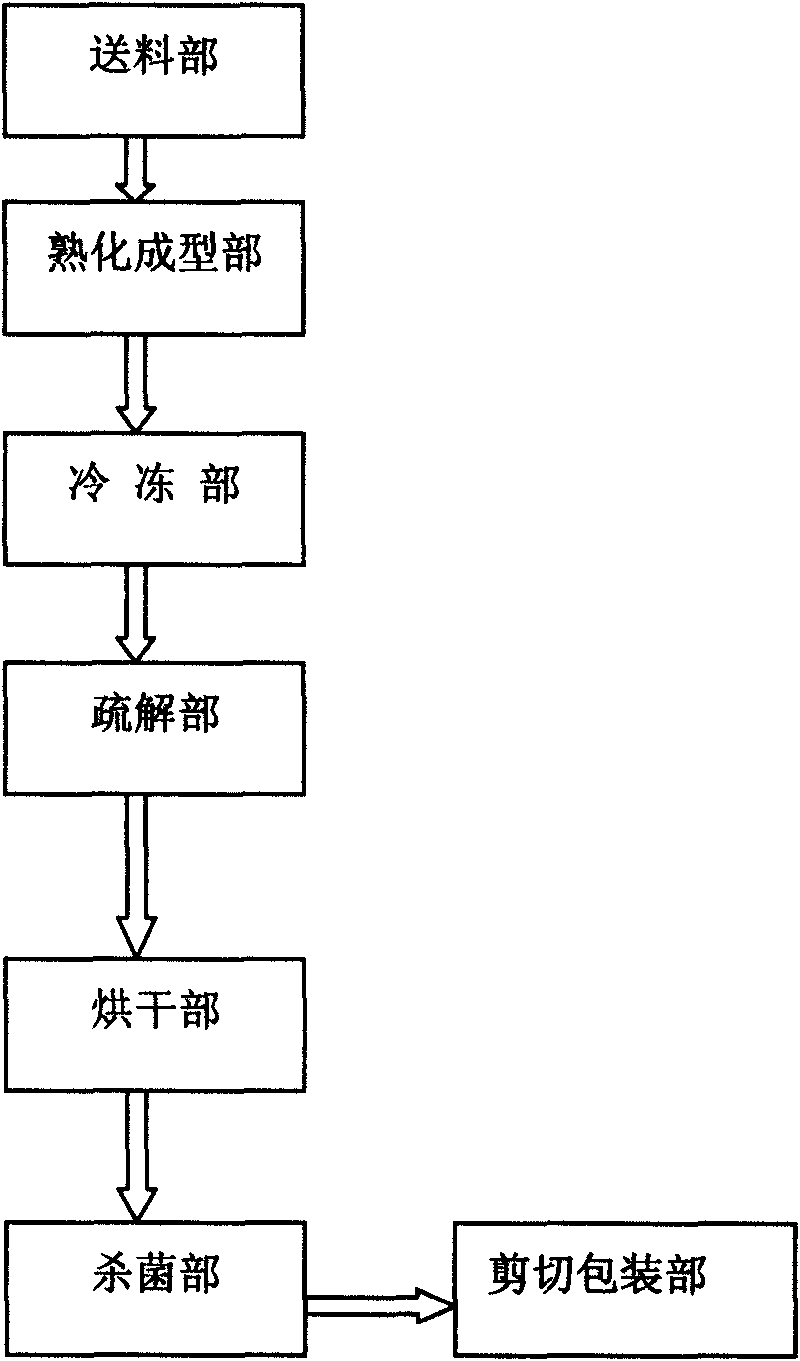

[0029] see Figure 1-7 , an automatic production system for vermicelli and vermicelli, comprising a feeding section, a ripening and forming section, a freezing section, a defrosting section, a drying section, a sterilization section and a cutting and packaging section.

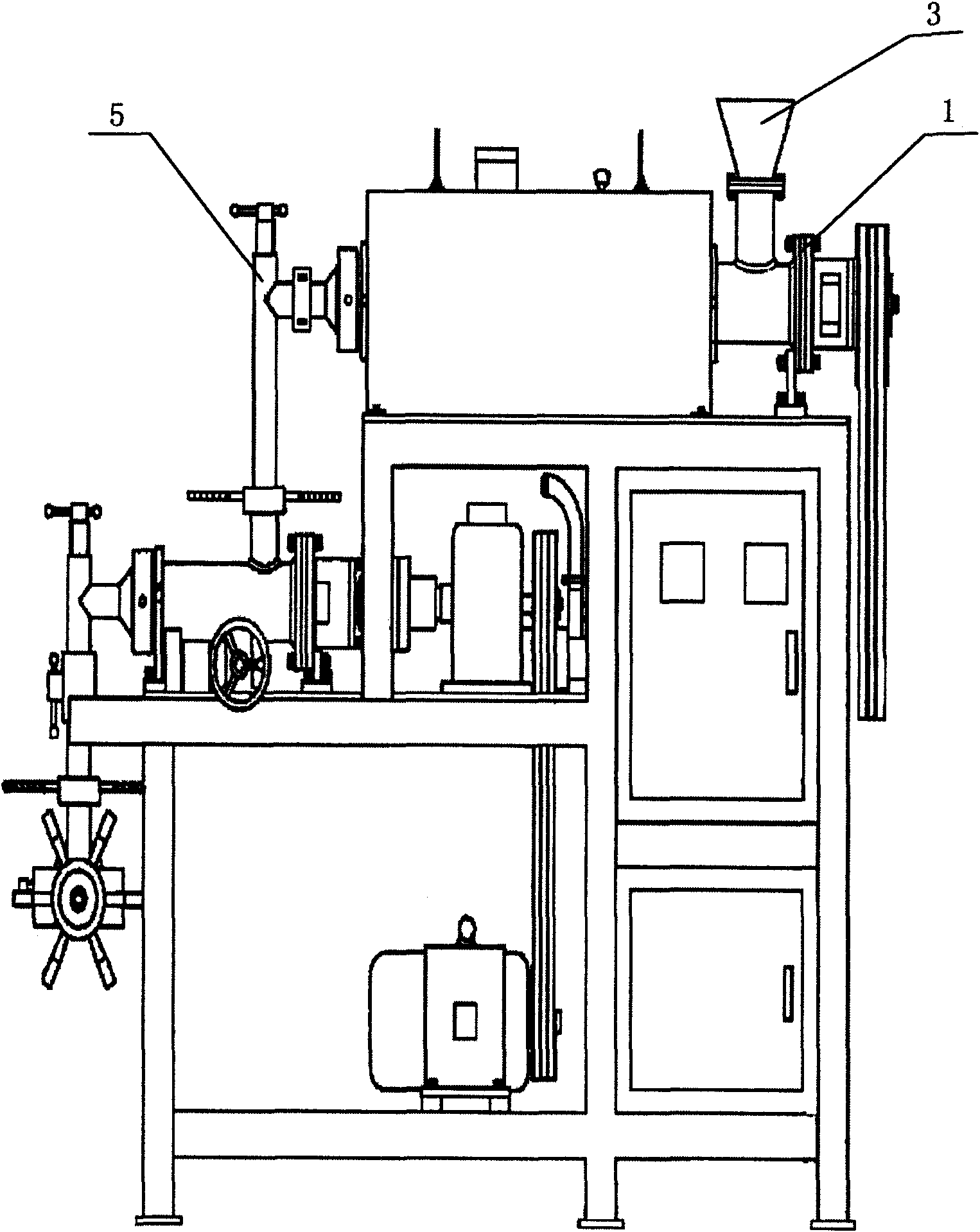

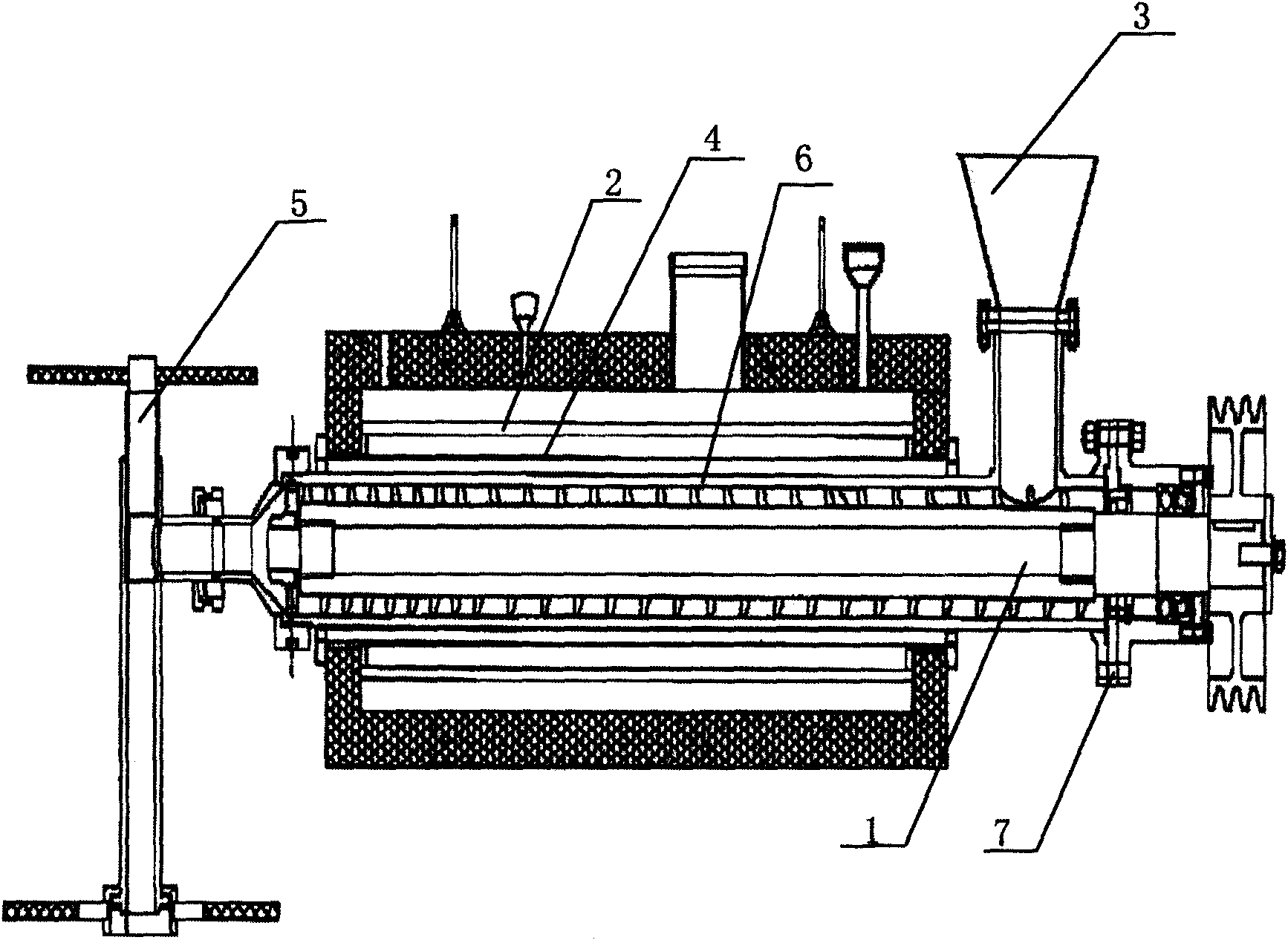

[0030] Said curing molding part includes a curing component, a high-pressure wire outlet component and an electric control mechanism, wherein the curing component includes a screw shaft 1 connected with a driving device, a feed port 3 and a discharge port 5, and the outer ring of the screw shaft 1 A casing 6 is provided. Said curing assembly also includes a sleeve 2, the sleeve 2 is arranged on the outside of the sleeve 6, and an electromagnetic heating device 4 is installed between the sleeve 2 and the sleeve 6, and the screw shaft 1 is close to the feeding port. One end of 3 is provided with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com