135 DEG C irradiation-crosslinked polyolefin heat-shrinkable tube

A technology of cross-linked polyolefin and heat-shrinkable tubes, which is applied in the field of irradiated cross-linked polyolefin heat-shrinkable tubes at 135°C, which can solve the problems of poor oil resistance, high equipment cost requirements, and non-stacking shrinkage, etc., to achieve extrusion processing Improved performance, improved surface quality, and reduced melt pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the above-mentioned 135 ℃ radiation cross-linked polyolefin heat-shrinkable tube comprises the following steps:

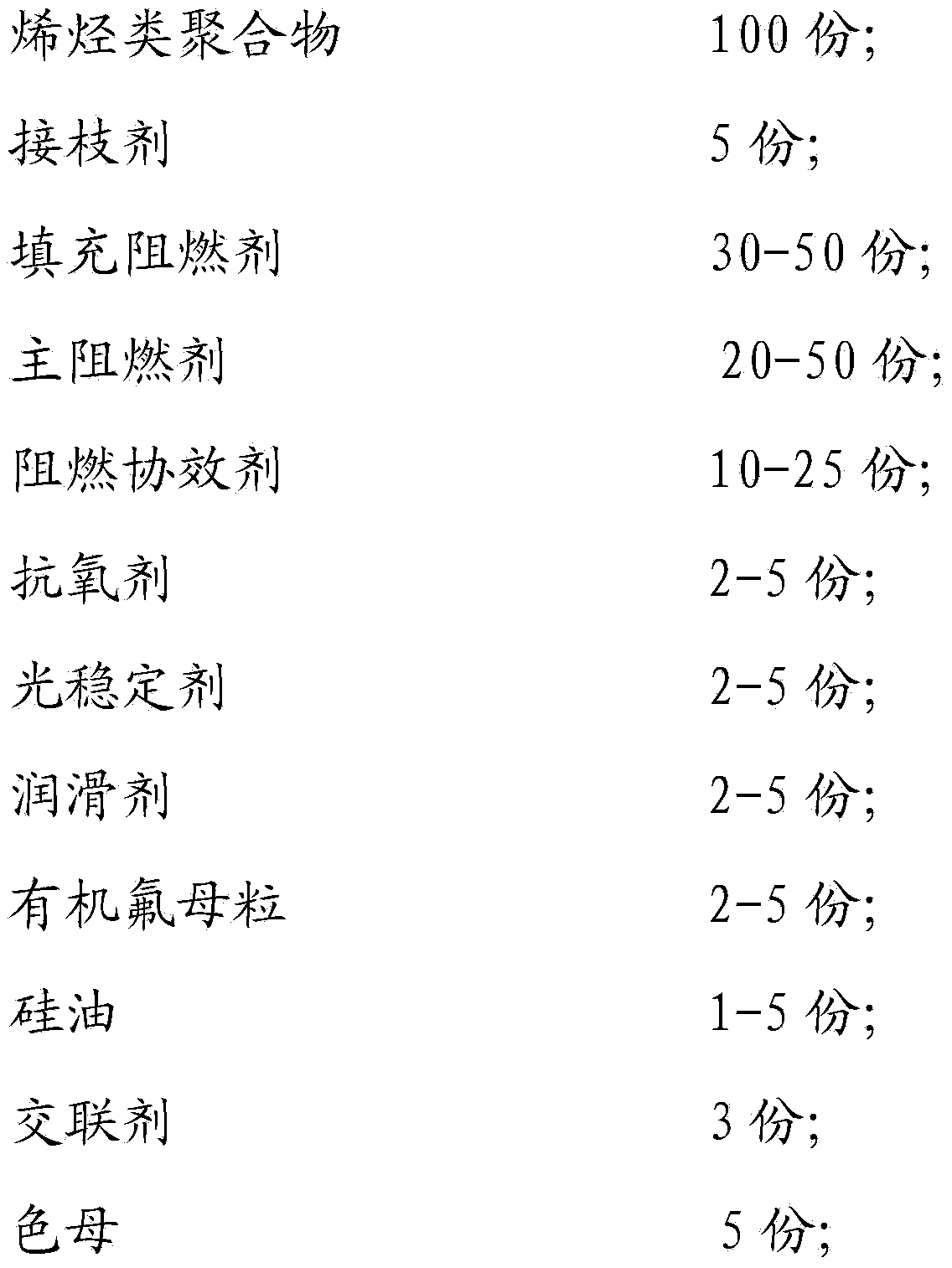

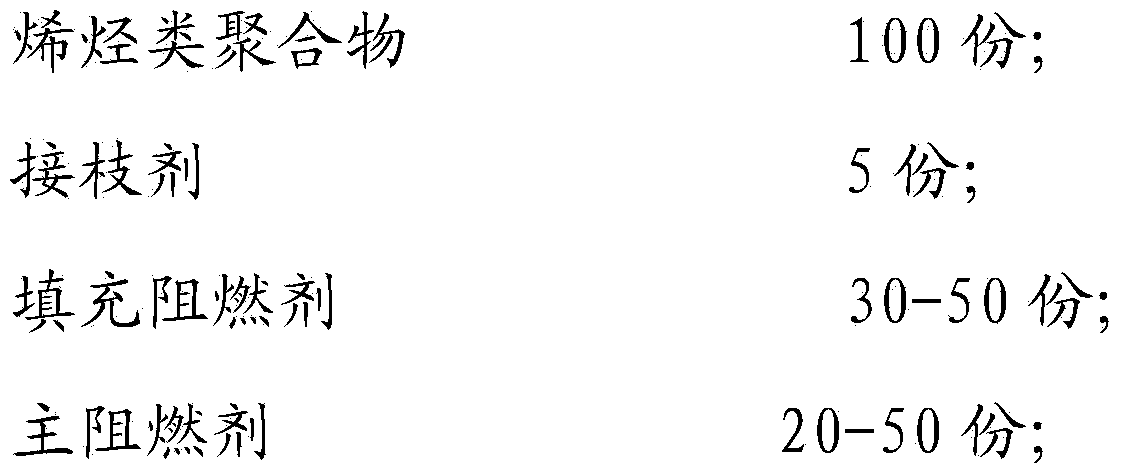

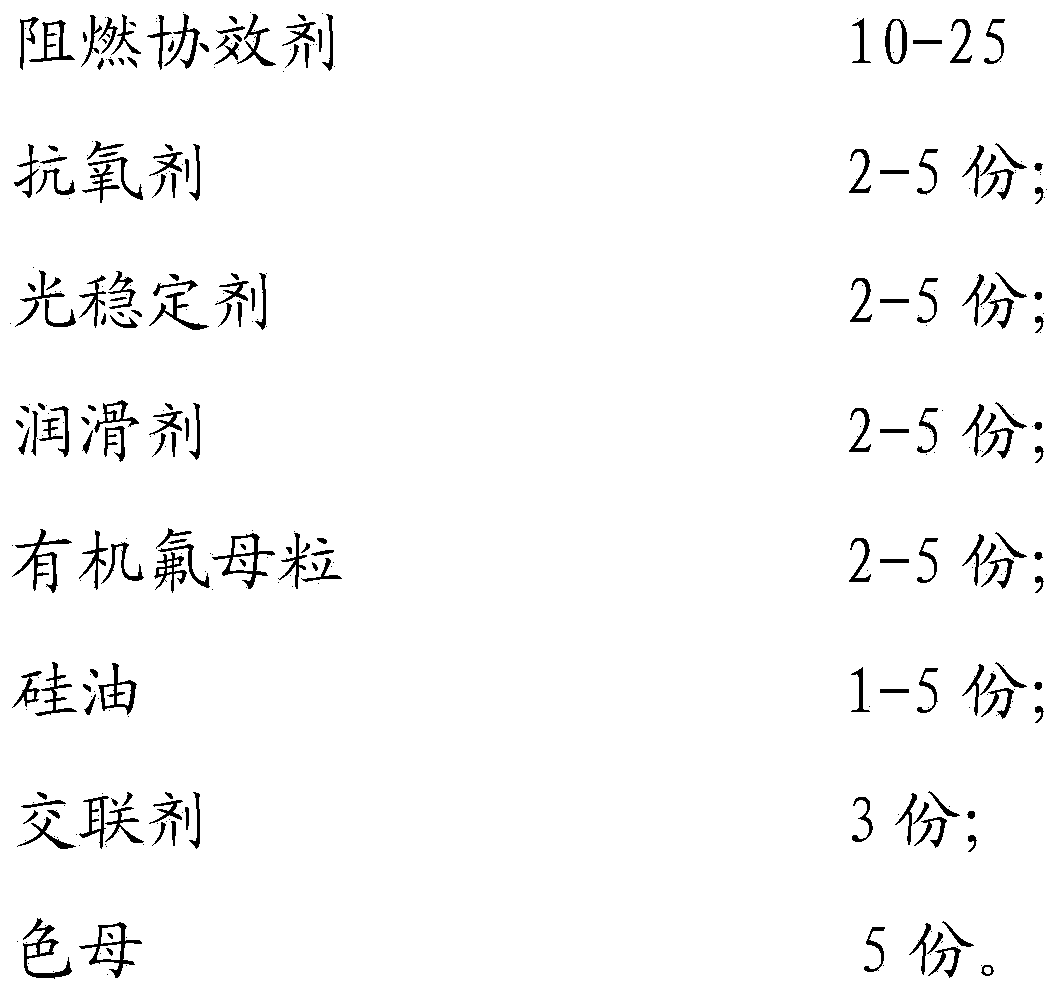

[0047] Step 1: Take the following components in parts by weight, 100 parts of olefin polymer; 5 parts of grafting agent; 30-50 parts of filling flame retardant; 20-50 parts of main flame retardant; flame retardant synergist 10-25 parts; 2-5 parts of antioxidant; 2-5 parts of light stabilizer; 2-5 parts of lubricant; 2-5 parts of organic fluorine masterbatch; 1-5 parts of silicone oil; Mother 5 copies.

[0048] Step 2: Stir the components in step 1 with a high-speed mixer, and produce a masterbatch at 100-160°C through an internal mixer or twin-screw.

[0049] Step 3: Process the masterbatch prepared in step 2 through a single-screw extruder, and shape and extrude a pipe under the condition of 90-160°C.

[0050] Step 4: The tube extruded in step 3 is irradiated in an electron accelerator, and the irradiation dose is 5-15 Mrad.

[00...

preparation Embodiment 1

[0053] Take the following components:

[0054] 100 parts of olefin polymers (specifically, 30Kg of ethylene methyl acrylate (EMA Akema 18MA03) and 70Kg of ethylene vinyl acetate (EVA));

[0055] 5 parts of grafting agent (concretely get maleic anhydride modified terpolymer 5Kg);

[0056] Fill with 50 parts of flame retardant (specifically take magnesium hydroxide 20Kg, aluminum hydroxide 30Kg);

[0057] 20 parts of main flame retardant (concretely get 20Kg of decabromodiphenylethane flame retardant);

[0058] 10 parts of flame retardant synergist (specifically take 10Kg of antimony trioxide);

[0059] 5 parts of antioxidant (specifically take antioxidant 10763Kg, antioxidant DNP 2Kg);

[0060] 2 parts of light stabilizer (specifically take 2Kg of tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite (brand: GW540))

[0061] 4 parts of lubricant (specifically take 2Kg of zinc stearate and 2Kg of silicone);

[0062] 2 parts of organic fluorine masterbatch (specifically take 2Kg ...

preparation Embodiment 2

[0071] Take the following components:

[0072] 100 parts of olefinic polymer (specifically take 80Kg of ethylene methyl acrylate (EMA Akema 18MA03) and 20Kg of ethylene octene copolymer resin (POE));

[0073] 5 parts of grafting agent (concretely get maleic anhydride modified copolymer 5Kg);

[0074] Fill with 30 parts of flame retardant (specifically take 30Kg of magnesium hydroxide);

[0075] 50 parts of main flame retardant (specifically take 40Kg of decabromodiphenylethane, 10Kg of decabromodiphenyl ether);

[0076] 25 parts of flame retardant synergist (specifically 5Kg of zinc borate and 20Kg of antimony trioxide);

[0077] 2 parts of antioxidant (specifically take antioxidant 10101.5Kg, antioxidant Ky4050.5Kg);

[0078] 2 parts of light stabilizer (specifically take 2Kg of tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite (brand: GW540))

[0079] 2 parts of lubricant (specifically take 2Kg of lubricant zinc stearate);

[0080] 5 parts of organic fluorine masterbatch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com