Air cushion belt type conveyor sweeper

A technology of belt conveyors and cleaners, applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc., can solve problems affecting the production plan of enterprises, falling on other equipment and the ground, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

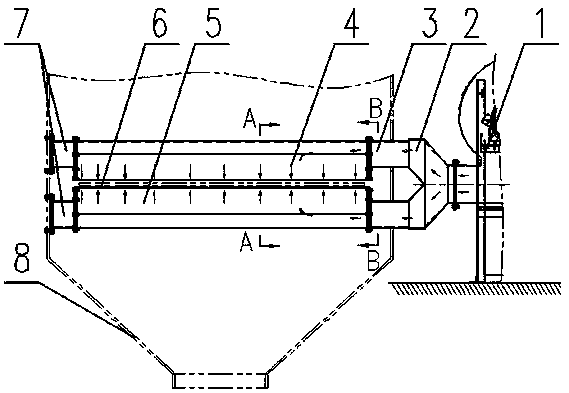

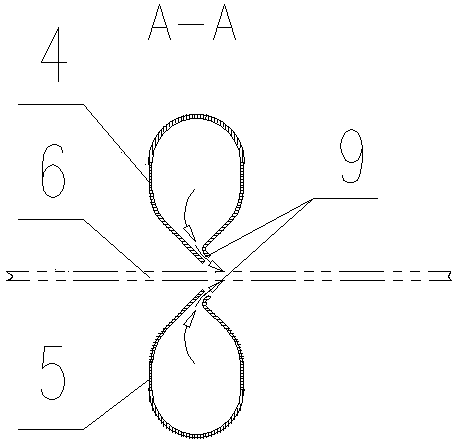

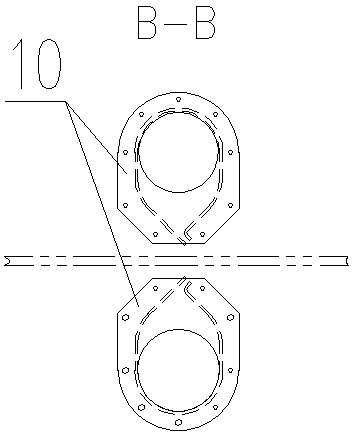

[0008] Combining the above drawings to describe the embodiment, what this technical solution adopts is that the high-pressure centrifugal fan 1 is a self-contained air source, and the high-pressure centrifugal fan is connected with the distribution box 2 by bolts through the flange, and the conveyor adjacent to the distribution box The side wall of the head hopper 8 is processed with two assembly holes through which the transition air pipe 3 passes. One end of the two transition air pipes penetrates into the assembly hole and is welded with the special-shaped flange 10, and the other end is welded with the air distribution box. One end of the strong wind pipe 4 and the lower strong wind pipe 5 is welded on the special-shaped flange 10-1, the special-shaped flange 10 and the special-shaped flange 10-1 are connected by bolts, and the other end is welded to another special-shaped flange 10-2, One end of the support pipe 7 is welded to the special-shaped flange 10-3, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com