Method for making blind slots of buried copper blocks in circuit boards

A production method and circuit board technology, which is applied in the fields of printed circuit manufacturing, printed circuits, electrical components, etc., can solve the problems of height difference of heating components and affect the heat dissipation effect of heating components, and achieve the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

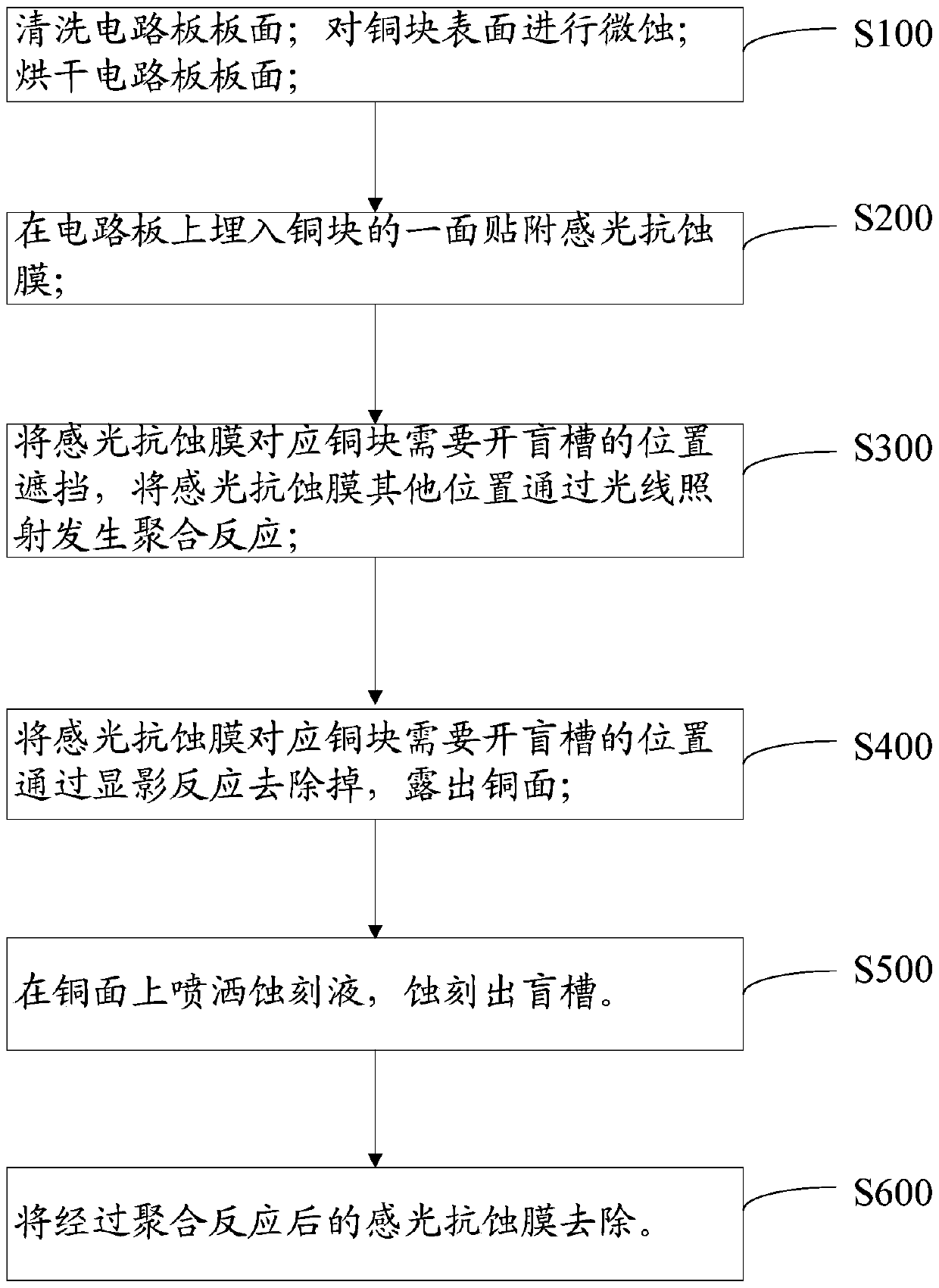

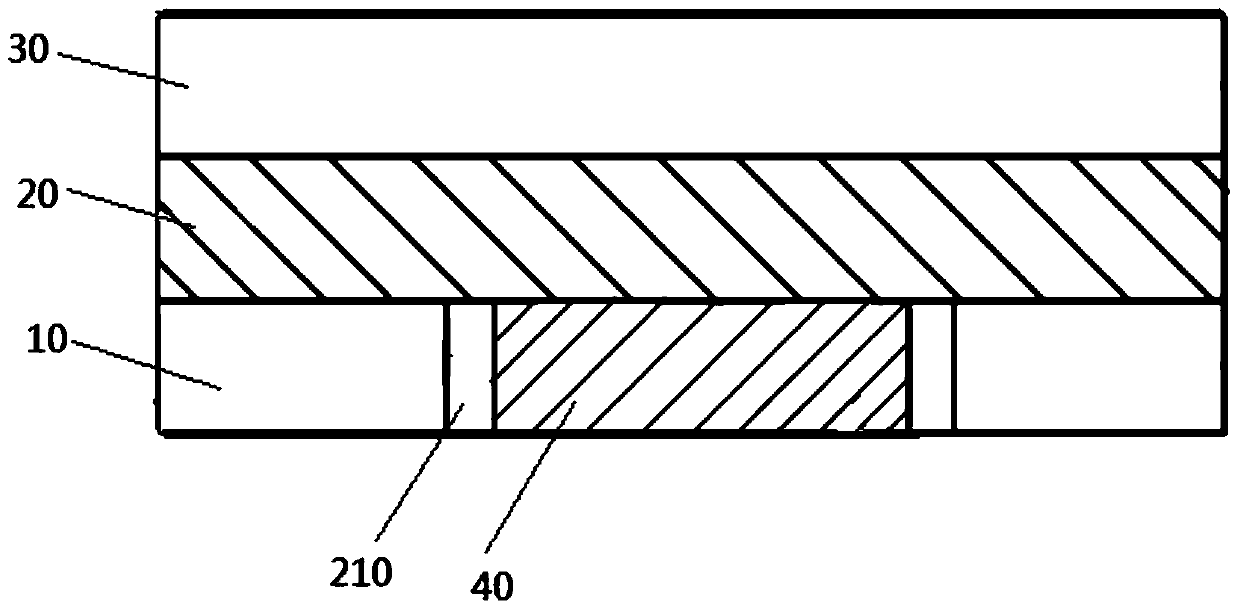

[0037] refer to figure 1 , 3 , a method for manufacturing a circuit board buried copper block blind slot, comprising the steps of:

[0038] S100: cleaning the surface of the circuit board; microetching the surface of the copper block 40; drying the surface of the circuit board.

[0039] S200: attaching a photosensitive resist film 50 on one side of the copper block 40 embedded in the circuit board;

[0040] S300: Covering the position of the photosensitive resist film 50 corresponding to the copper block 40 where the blind groove 110 needs to be opened, and irradiating other positions of the photosensitive resist film 50 with light to undergo a polymerization reaction;

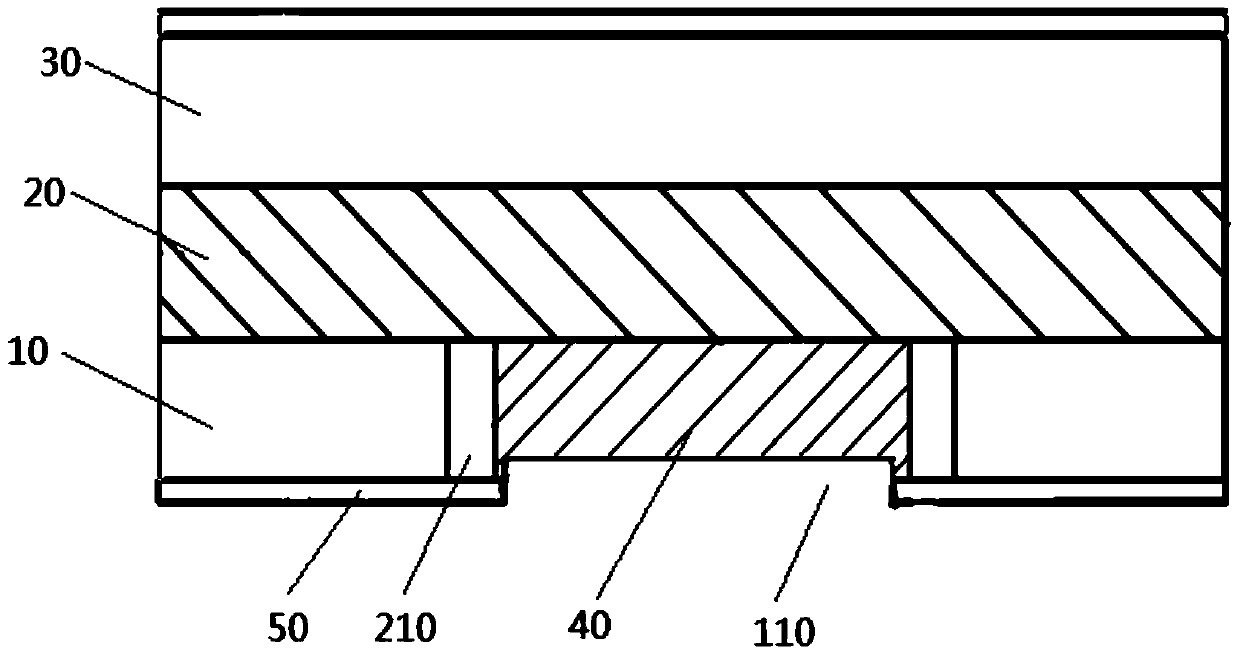

[0041] S400: removing the position of the photosensitive resist film 50 corresponding to the copper block 40 where the blind groove 110 needs to be opened, through a developing reaction, to expose the copper surface;

[0042] S500: Spray an etchant on the copper surface to etch the blind groove 110 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com