Upright pure mechanical drilling rod mud scrapping device

A purely mechanical and mud scraper technology, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well parts, etc., can solve the problems of low manual mud scraping efficiency and large number of drill pipes, so as to improve the drilling efficiency and reduce the The effect of labor intensity and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

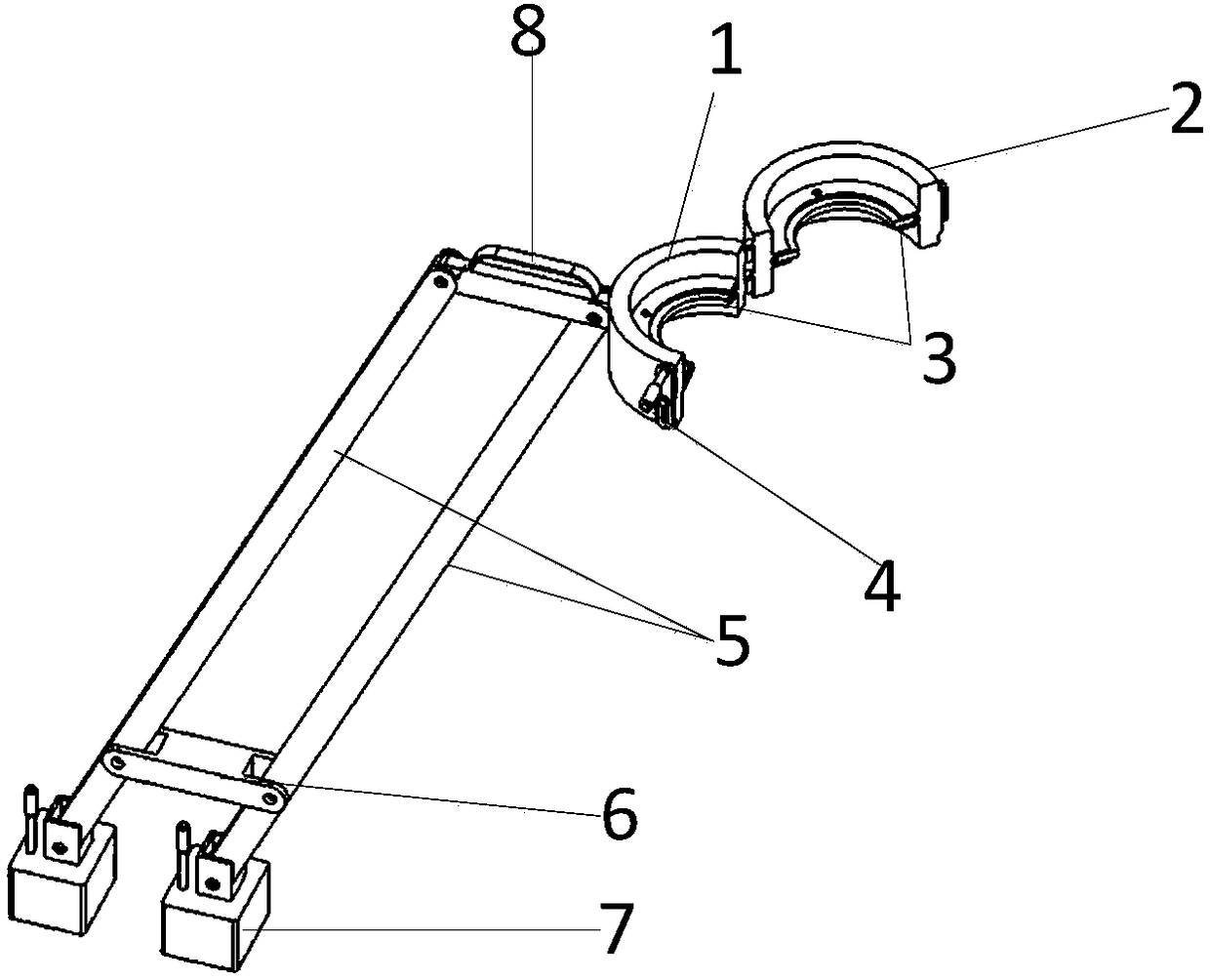

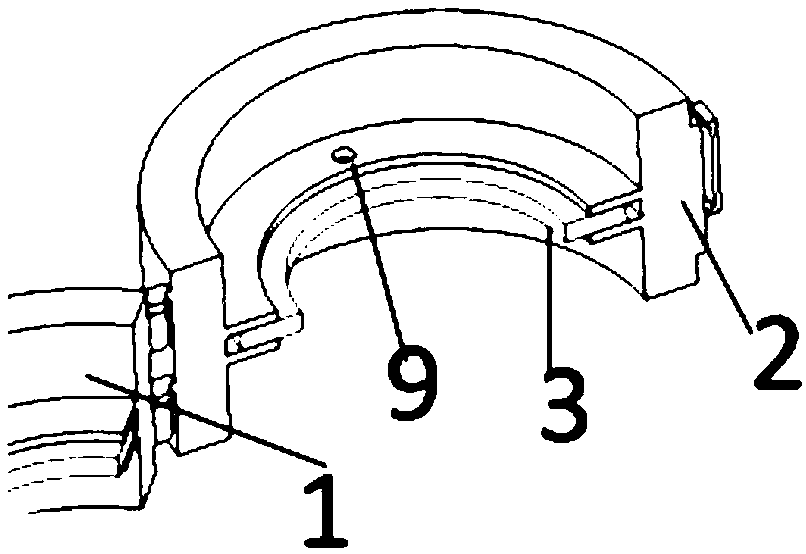

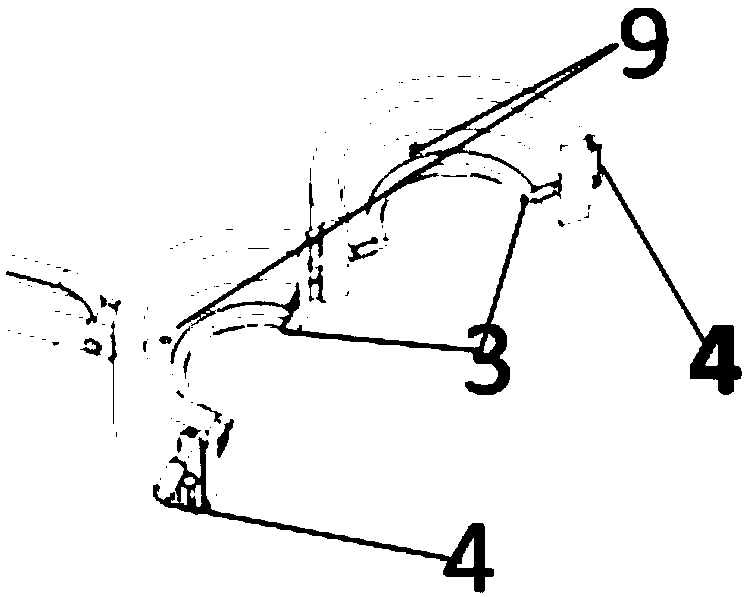

[0017] Such as figure 1 figure 2 Shown: a vertical purely mechanical drill pipe mud scraper, including two powerful magnet suction cups 7 adsorbed on the drill floor next to the wellhead. There are uprights 5, and the uprights 5 are arranged horizontally with each other, and the top of the uprights 5 is provided with a working grip 8, and the working grip 8 is provided with a semicircular left casing 1, and one end of the left casing 1 is connected with a semicircular Shaped right housing 2, the other end is provided with a locking mechanism 4 that can fasten the left housing 1 and the right housing 2, and the left housing 1 and the right housing 2 are provided with ring-shaped rubber mud scrapers 3. The left casing 1 and the right casing 2 are buckled together to form a ring structure.

[0018] The inside of the left housing 1 and the right housing 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com