High-efficiency crystalline silicon heterojunction solar cell silicon wafer cleaning device and method

A technology for cleaning solar cells and silicon wafers. It is used in the manufacture of circuits, electrical components, and semiconductor/solid-state devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

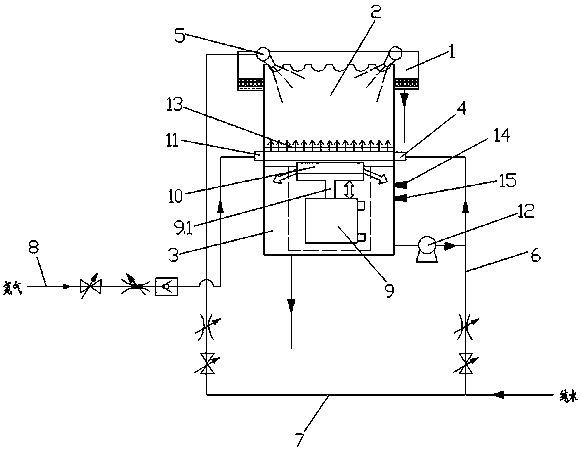

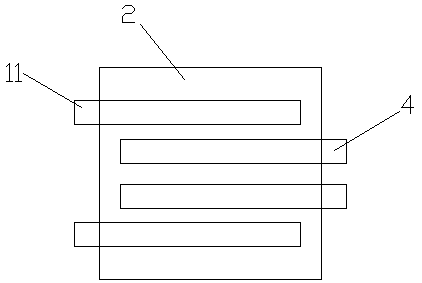

Method used

Image

Examples

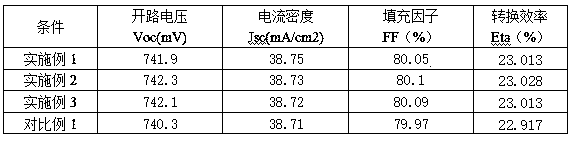

Embodiment 1

[0040] a. Adopt the above-mentioned cleaning method to carry out texturing and cleaning treatment to the N-type monocrystalline silicon wafer (180um) with a size of 156.75mm. The cleaning time is 50s for overflow and 70s for spraying;

[0041] b. The intrinsic amorphous silicon layer on the back is prepared by PECVD, and the 7nm deposition is completed in one step;

[0042] c. Selecting the n-type amorphous silicon film as the doped layer on the light-receiving surface. Using plasma-enhanced chemical vapor deposition to prepare an n-type amorphous silicon layer with a thickness of 6 nm;

[0043] d. Use plasma chemical vapor deposition to prepare a p-type amorphous silicon layer with a total thickness of 10 nm;

[0044] e. Use (RPD, PVD) method to deposit TCO conductive film with a thickness of 100nm;

[0045] f. Form front and back silver metal electrodes by screen printing;

[0046] g. Curing makes a good ohmic contact between the silver grid line and the TCO;

[0047] h....

Embodiment 2

[0049] Same as Example 1, except that the cleaning time is 70s for overflow and 50s for spraying.

Embodiment 3

[0051] Same as Example 1, except that the cleaning time is 90s for overflow and 30s for spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com