Chemical pipeline cleaning device

A cleaning device and pipeline technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of unclean cleaning and slipping, achieve clean cleaning, improve cleaning efficiency, and have a large contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

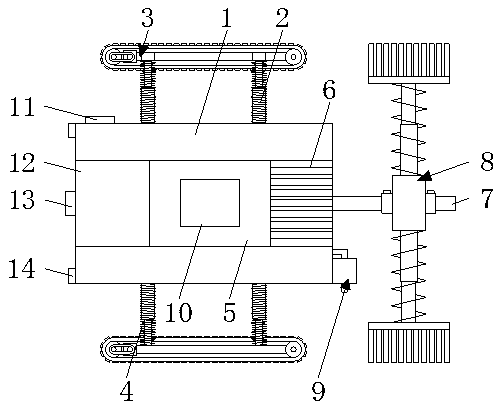

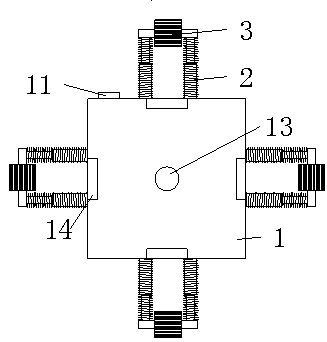

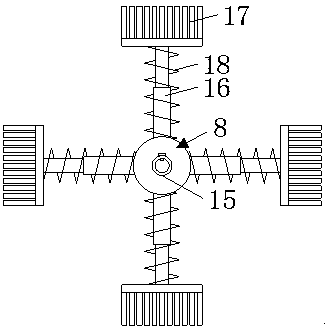

[0026] A chemical pipeline cleaning device, comprising a bracket 1, the surface of the bracket 1 is connected with a driving device 3 through a first telescopic rod 2, the surface of the first telescopic rod 2 is covered with a first spring 4, and a battery is installed inside the bracket 1 5 and the cleaning motor 6, the cleaning motor 6 is connected with the cleaning brush 8 through the rotating shaft 7, the driving device 3 is made up of the support plate 19, the driving wheel 20, the driven wheel 21, the driving motor 22 and the rubber track 23, the driving wheel 20 and the driven wheel 21 Respectively rotate and be connected to the two ends of support plate 19, drive motor 22 is installed on the surface of support plate 19, drive motor 22 drives driving wheel 20 to rotate by transmission belt, and driving wheel 20 rotates by rubber track 23 driven driven wheel 21, and rubber track 23 Anti-slip protrusions 24 are provided on the surface.

[0027] In this technical solution...

Embodiment 2

[0029] A chemical pipeline cleaning device, comprising a bracket 1, the surface of the bracket 1 is connected with a driving device 3 through a first telescopic rod 2, the surface of the first telescopic rod 2 is covered with a first spring 4, and a battery is installed inside the bracket 1 5 and the cleaning motor 6, the cleaning motor 6 is connected with the cleaning brush 8 through the rotating shaft 7, the driving device 3 is made up of the support plate 19, the driving wheel 20, the driven wheel 21, the driving motor 22 and the rubber track 23, the driving wheel 20 and the driven wheel 21 Respectively rotate and be connected to the two ends of support plate 19, drive motor 22 is installed on the surface of support plate 19, drive motor 22 drives driving wheel 20 to rotate by transmission belt, and driving wheel 20 rotates by rubber track 23 driven driven wheel 21, and rubber track 23 The surface is provided with anti-slip protrusions 24, and the cleaning brush 8 is compose...

Embodiment 3

[0032] A chemical pipeline cleaning device, comprising a bracket 1, the surface of the bracket 1 is connected with a driving device 3 through a first telescopic rod 2, the surface of the first telescopic rod 2 is covered with a first spring 4, and a battery is installed inside the bracket 1 5 and the cleaning motor 6, the cleaning motor 6 is connected with the cleaning brush 8 through the rotating shaft 7, the driving device 3 is made up of the support plate 19, the driving wheel 20, the driven wheel 21, the driving motor 22 and the rubber track 23, the driving wheel 20 and the driven wheel 21 Respectively rotate and be connected to the two ends of support plate 19, drive motor 22 is installed on the surface of support plate 19, drive motor 22 drives driving wheel 20 to rotate by transmission belt, and driving wheel 20 rotates by rubber track 23 driven driven wheel 21, and rubber track 23 The surface is provided with anti-slip protrusions 24, and the cleaning brush 8 is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com